Preparation method of magnetic molecularly imprinted polymer for separating/purifying sudan I

A magnetic molecular imprinting and Sudan red technology, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of low selectivity and easy damage to the spatial structure of polymers, and achieve the effect of rapid detection and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

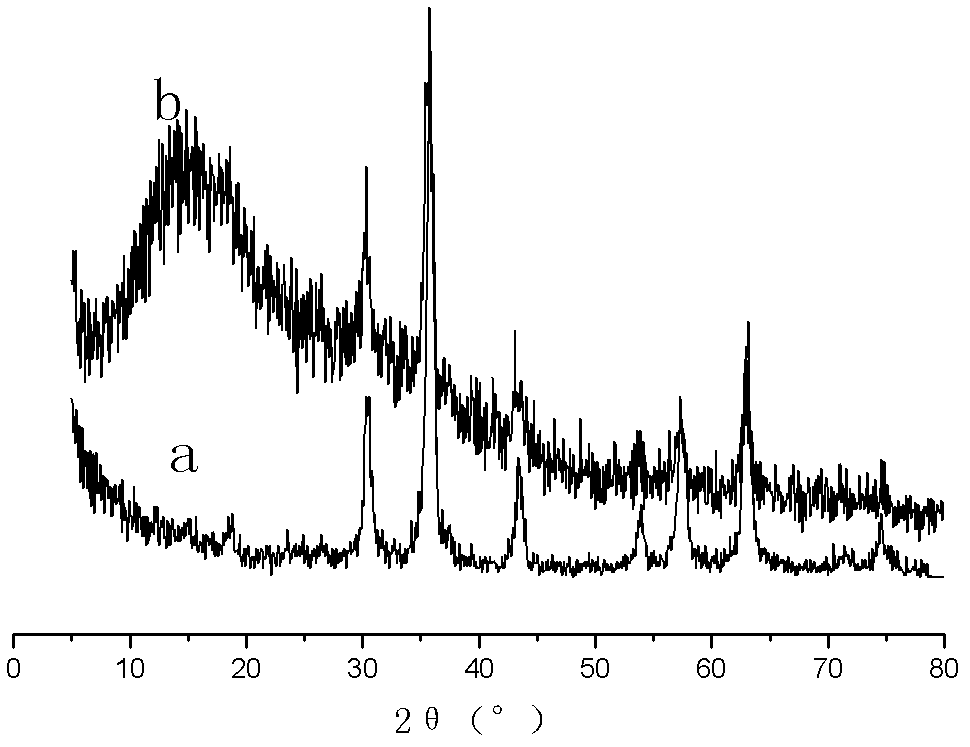

[0027] (1) Take 80mL H 2 O was added to the three-necked flask, deoxygenated by nitrogen for half an hour, and then 9.56g FeCl was added 3 ·6H 2 O and 5.60 g FeSO 4 ·7H 2 O, the three-necked bottle was placed in a 65°C constant temperature oil bath, stirred rapidly, and after 30 minutes, concentrated ammonia water was added dropwise to pH = 8-9, and the color gradually became black, and Fe was formed at this time 3 o 4 precipitation. The whole reaction process was carried out under the protection of nitrogen. After 1 h, use a strong magnet to settle the resulting granular product, separate the supernatant, and wash with H successively. 2 O and absolute ethanol to wash the precipitate to neutrality.

[0028] (2) Unmodified Fe 3 o 4 There are a large number of hydroxyl groups on the surface of the particles, which are not easy to disperse in organic solvents. When preparing molecularly imprinted polymers, they are mostly distributed on the surface of the polymer and are...

Embodiment 2

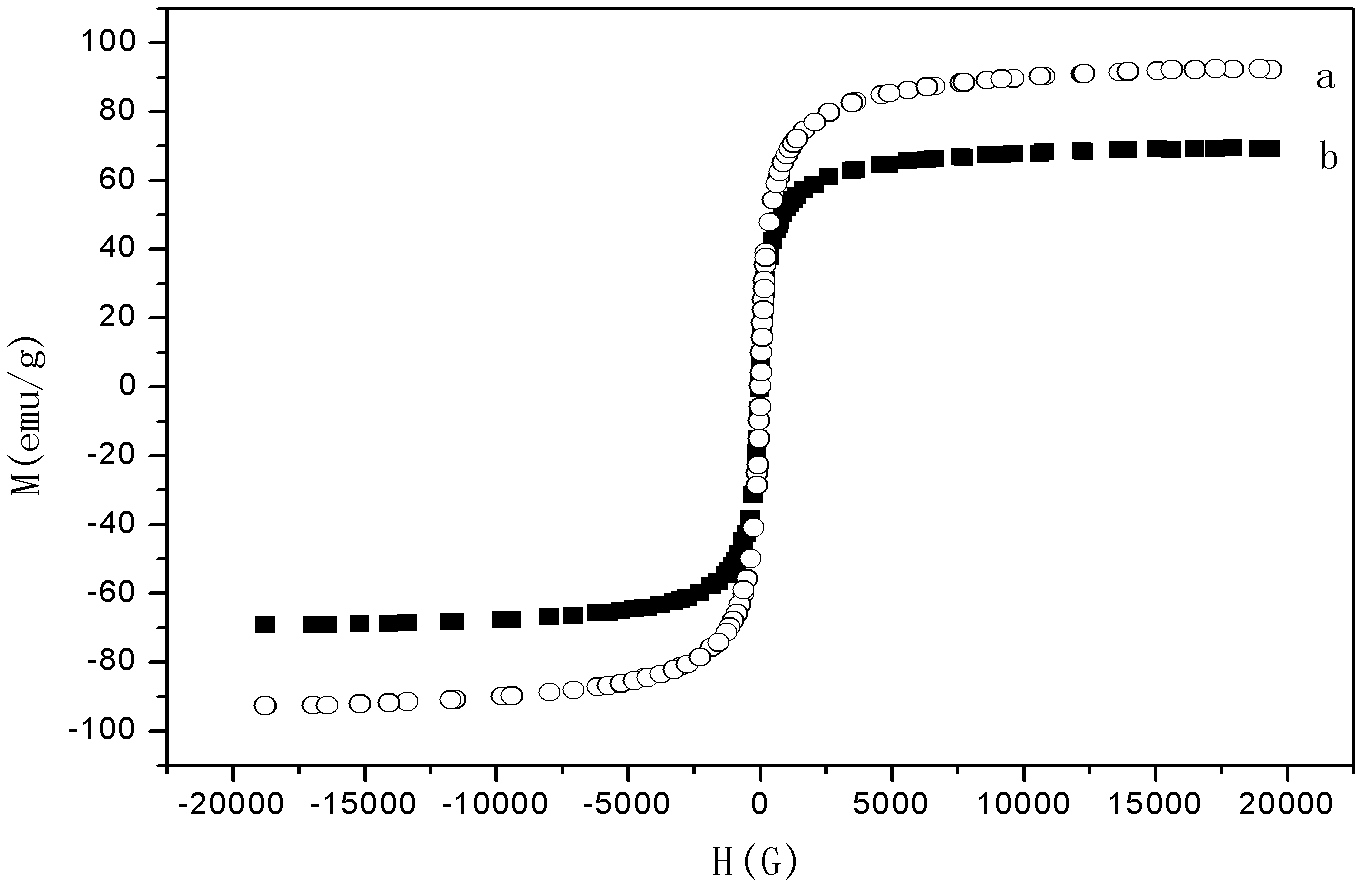

[0035] Weigh 1mmol of Sudan I and 4mmol of methacrylic acid (MAA), place in a 250mL Erlenmeyer flask, add 180mL of acetonitrile, and sonicate for half an hour to mix well. Then add 3.00mL of cross-linking agent ethylene glycol dimethacrylate (EGDMA), 10mL of acetonitrile-based magnetic fluid prepared in Example 1 and 1.0g of initiator azobisisobutyronitrile (AIBN), and continue to sonicate. Nitrogen gas was passed for 1 h to remove the oxygen in the system, and the reaction was carried out in an air shaker at 60° C. for 24 h. Take it out and cool it to room temperature, add methanol / acetic acid (85:15, V / V) solution to ultrasonic for 30min, filter through a Buchner funnel, then use the same solution for Soxhlet extraction for 48h until no Sudan I molecules can be detected, and then use acetone Repeated sedimentation to remove fine powder, and finally vacuum dried at 60°C for 24h.

Embodiment 3

[0037] Weigh 1mmol Sudan I and 4mmol methacrylic acid (MAA), place in a 250mL Erlenmeyer flask, add 180mL acetonitrile, and ultrasonically mix for half an hour. Then add 1.5mL of cross-linking agent ethylene glycol dimethacrylate (EGDMA), 10mL of acetonitrile-based magnetic fluid prepared in Example 1 and 1.0g of initiator azobisisobutyronitrile (AIBN), and continue to sonicate. Nitrogen was passed for 1 h to remove the oxygen in the system, and the reaction was carried out in an air shaker at 65° C. for 24 h. Take it out and cool it to room temperature, add methanol / acetic acid (85:15, V / V) solution and sonicate for 20min, filter through a Buchner funnel, and then perform Soxhlet extraction with the same solution for 48h until no Sudan I molecules can be detected, and then use acetone Repeated sedimentation to remove fine powder, and finally vacuum dried at 60°C for 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com