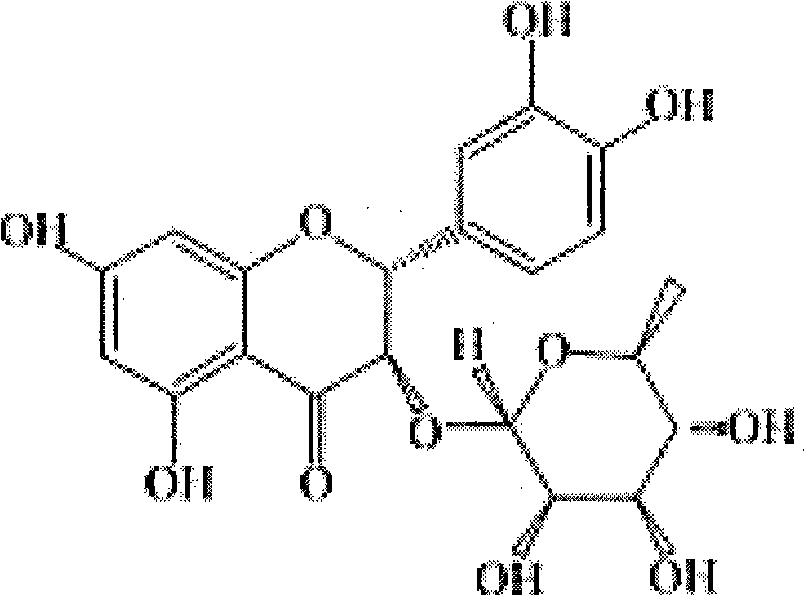

Method for extracting astilbin from china root

A technology of astilbin and smilax, which is applied in the field of extracting astilbin, which can solve the problems of increased environmental burden, low specificity, and high production cost, and achieves the effects of easy industrial scale-up, high purification specificity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take 2 kg of Smilax cocos (astilbin content 0.23%), grind it into 20 meshes, add 16 L of water, reflux extraction for 1 hour, extract 3 times, and combine the extracts. The extract was concentrated in vacuum to 1 / 4 of the original volume, 2% sodium chloride was added while it was hot, acidified with hydrochloric acid with stirring until the pH was 2, the flavonoids were precipitated, and filtered. The filtrate was further diluted with water and filtered. Combine the two filter cakes and add 2 times the amount of ethyl acetate to degrease. The dry degreased solid is saturated and dissolved with 90% ethanol. The sample is mixed with AB-8 macroporous resin, and the water-soluble impurities are first eluted with water at a flow rate of 2BV / h until it flows The product was colorless, and then eluted with 10% ethanol at a flow rate of 2BV / h until astilbin was detected, and finally eluted with 60% ethanol at a flow rate of 2BV / h to obtain astilbin eluate. Astilbin was deliqui...

Embodiment 2

[0036] Take 2 kg of Smilax cocos (astilbin content 0.28%), grind it into 20 meshes, add 12 L of water, reflux extraction for 2 hours, extract twice, and combine the extracts. The extract was concentrated in vacuum to 1 / 5 of the original volume, 3% sodium chloride was added while it was hot, acidified with hydrochloric acid to pH 2 after stirring, and the flavonoids were precipitated, and filtered. The filtrate was further diluted with water and filtered. Combine two filter cakes and add 3 times the amount of ethyl acetate to degrease, and the dried degreased solid is saturated and dissolved with 95% ethanol, and the mixed sample is saturated with AB-8 macroporous resin for adsorption, and the water-soluble impurities are firstly eluted with water at a flow rate of 2BV / h Until the effluent is colorless, then elute with 30% ethanol at a flow rate of 2BV / h until astilbin is detected, and finally use 80% ethanol at a flow rate of 2BV / h to wash off astilbin to obtain an astilbin el...

Embodiment 3

[0038] Take 2 kg of Smilax cocos (astilbin content 0.3%), pulverize into 30 mesh, add 15 L of water, reflux extraction for 1 hour, extract 3 times, and combine the extracts. The extract was concentrated in vacuum to 1 / 4 of the original volume, 2% sodium chloride was added while it was hot, acidified with hydrochloric acid to pH 1 after stirring, the flavonoids were precipitated, and filtered. The filtrate was further diluted with water and filtered. Combine the two filter cakes and add 2 times the amount of ethyl acetate to degrease. The dry degreased solid is saturated and dissolved with 90% ethanol, and the mixed sample is saturated with HPD-400 macroporous resin for adsorption. First, water-soluble impurities are eluted with water at a flow rate of 2BV / h Until the effluent is colorless, elute with 50% ethanol at a flow rate of 2BV / h until astilbin is detected, and finally use 90% ethanol at a flow rate of 2BV / h to wash off astilbin to obtain an astilbin eluate. Astilbin wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com