Low-temperature co-fired ceramic substrate material and preparation method thereof

A low-temperature co-fired ceramic and ceramic substrate technology is applied in the field of electronic substrate materials to achieve the effects of excellent dielectric properties, cost reduction and low dielectric constant.

Active Publication Date: 2013-06-19

威海圆环先进陶瓷股份有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the development of modern technology requires electronic equipment to be reduced in size and weight, and the integration of a single active device can no longer meet production applications, so the miniaturization of passive devices has become inevitable.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

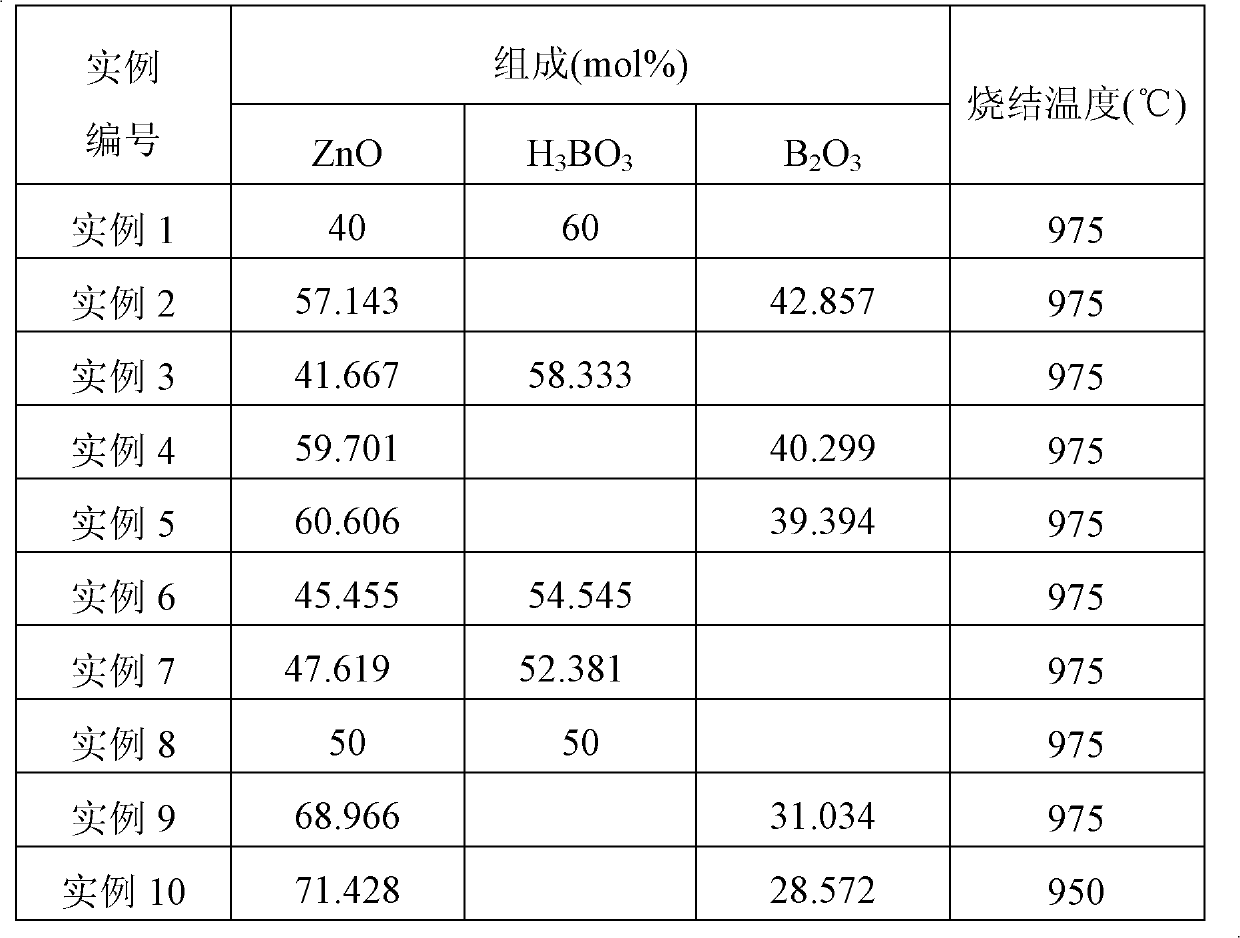

example 1

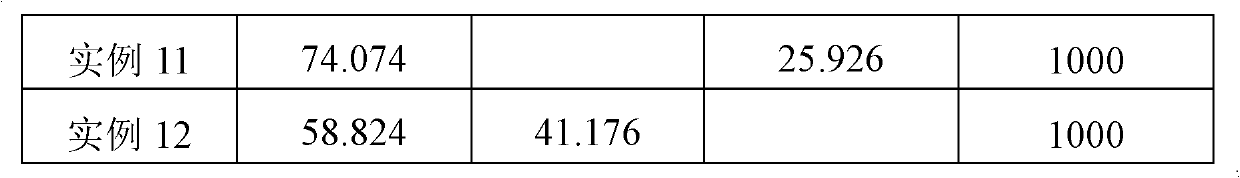

example 13~18

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a low-temperature co-fired ceramic substrate material and a preparation method thereof. The ceramic substrate material is zinc borate ceramic of which the main crystalline phase is 3ZnO.B2O3. The ceramic raw material consists of the components of ZnO and H3BO3, wherein the mole percent of the H3BO3 is 60-41.176%, or the raw material consists of chemical components of ZnO and B2O3, wherein the mole percent of the B2O3 is 42.857-25.926%. The preparation method of the ceramic substrate material comprises the steps of firstly presintering to combine 3ZnO.B2O3 powder, then adding deionized water, ball milling, drying, granulating, tableting and sintering. The material disclosed by the invention has a low sintering temperature (950-1000 DEG C) and good microwave dielectric performances: dielectric constant epsilon r = 6.5-6.9, Q*f = 26400-44600 GHz, and the resonant frequency temperature coefficient = -66 to -94 ppm / K, and the dielectric performance requirement of a high-frequency high-speed circuit on the substrate material can be met.

Description

technical field The invention belongs to the field of electronic substrate materials, in particular to a low-temperature co-fired ceramic substrate material and a preparation method thereof. Background technique With the rapid development of modern information technology, the miniaturization, light weight, integration and high frequency of electronic circuits have put forward requirements for small size, high frequency, high reliability and high integration of electronic components. The microelectronics technology based on the integration of active devices has been developed relatively well, and once became the main technology for the miniaturization of electronic devices. However, the development of modern technology requires electronic equipment to be reduced in size and weight, and the integration of a single active device can no longer meet production applications, so the miniaturization of passive devices has become inevitable. At present, small and medium-sized passiv...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B35/453C04B35/622

Inventor 周东祥胡云香傅邱云龚树萍郑志平赵俊刘欢韦东梅

Owner 威海圆环先进陶瓷股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com