Straw fiber board manufacturing method and liquid ball mill with plastic lining boards

A technology for straw fibers and a manufacturing method, which is applied in the field of plastic lining liquid ball mills, can solve problems such as difficulties, and achieve the effects of uniform particles, smooth surface and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

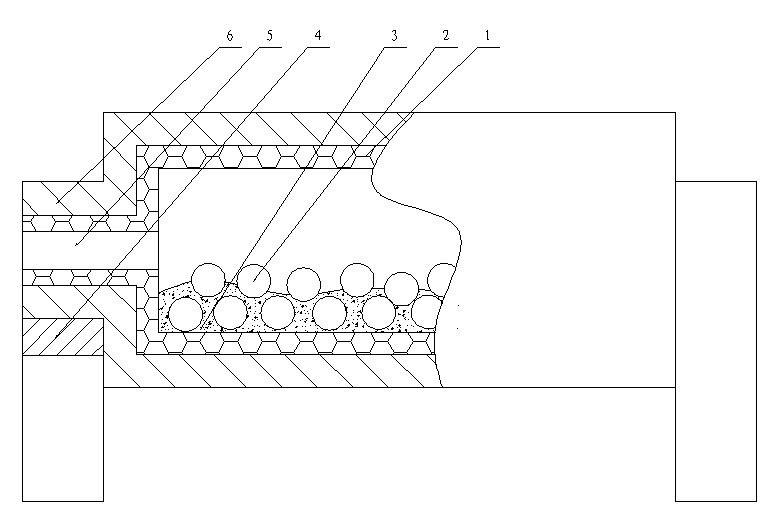

Image

Examples

Embodiment 1

[0020] A kind of manufacture method of straw fiber board, its steps are as follows:

[0021] (1) Cut the wheat straw into 5-15mm sections, remove broken leaves and sediment impurities, and then remove iron through a magnetic drum;

[0022] (2) Stir and disperse the straw blocks, put them into the plastic liner liquid ball mill, and then inject water. The amount of water added is based on the immersion of the straw, and hydrofluoric acid is added. The concentration of hydrofluoric acid is 47%, and the pH is adjusted to 5-6, washed with water after stirring until the pH is 6-7, and then centrifuged;

[0023] by chemical formula SiO 2 + 4HF = SiF 4 + 2H 2 O, 4 SiF 4 + 3H 2 O+ 2HF = 3H 2 SiF 6 + H 2 SiO 3 , before large-scale production, according to the straw in different regions, add hydrofluoric acid according to different straw amounts, check the pH value after grinding, find out the amount of hydrofluoric acid added per unit weight corresponding to the pH after g...

Embodiment 2

[0030] A kind of manufacture method of straw fiber board, its steps are as follows:

[0031] (1) Cut the wheat straw into 5-15mm sections, remove broken leaves and sediment impurities, and then remove iron through a magnetic drum;

[0032] (2) Stir and disperse the straw blocks, put them into the plastic liner liquid ball mill, and then inject water. The amount of water added is based on the immersion of the straw, and hydrofluoric acid is added. The concentration of hydrofluoric acid is 47%, and the pH is adjusted to 5-6, then add sulfuric acid, the amount of sulfuric acid added is 1 / 10 of the amount of hydrofluoric acid, the purpose is to remove the suberin cells of the straw, wash with water after stirring until the pH is 6-7, and then centrifuge ;

[0033] by chemical formula SiO 2 + 4HF = SiF 4 + 2H 2 O, 4 SiF 4 + 3H 2 O+ 2HF = 3H 2 SiF 6 + H 2 SiO 3 , before large-scale production, according to the straw in different regions, add hydrofluoric acid according...

Embodiment 3

[0040] A method for manufacturing a straw fiberboard, the same as in Embodiment 1, replacing wheat straw with corn stalks.

[0041] In an embodiment, the performance test of the straw fiberboard is as follows:

[0042] sample Density (kg / cm 3 ) Internal bonding strength / MPa Static Bending Strength / MPa Elastic modulus / MPa Board screw holding force / N Example 1 950 0.60 40 3000 1600 Example 2 880 0.58 30 2800 1650 Example 3 920 0.50 25 2500 1500 Example 4 900 0.55 35 2600 1580

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com