Multi-cavity plasma generator anode

A plasma generator and multi-chamber technology, applied in the direction of plasma, can solve the problems of low output power and short service life, and achieve the effect of stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

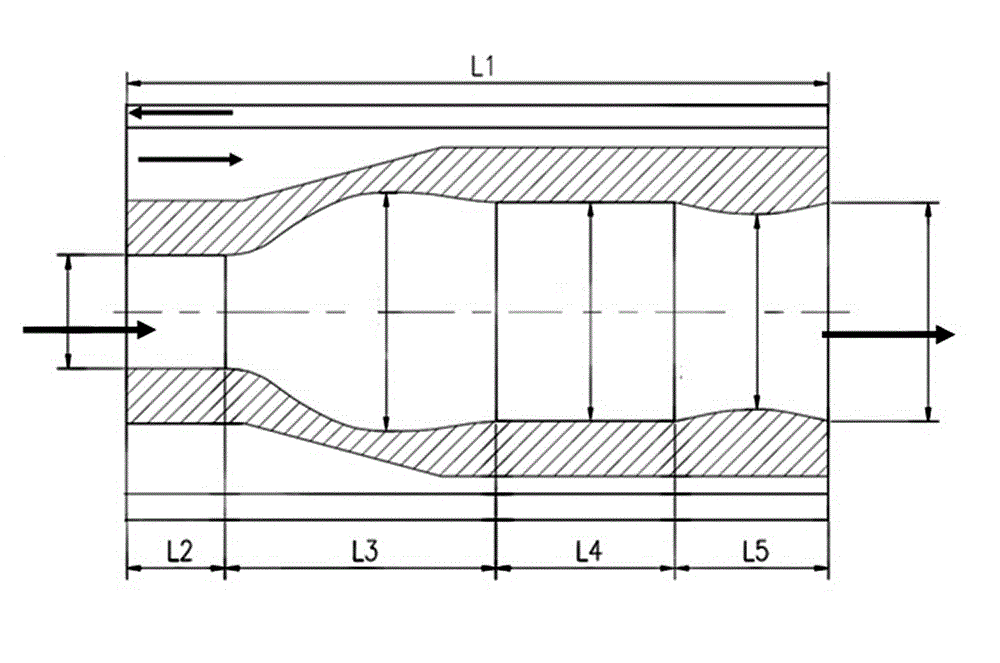

[0025] Such as figure 1 as shown, figure 1It is a structural diagram of a preferred embodiment of the multi-chamber plasma generator anode of the present invention. The anode of the multi-chamber plasma generator consists of a compression chamber L2, a combustion stabilization chamber L3, a diversion chamber L4, an acceleration chamber L5 and a water cooling system L1. The compression chamber L2 is located at the rear end of the anode, with a diameter of 20-60mm, a length of 20-50mm, and a thickness of 5-20mm, which mainly compresses the plasma generated by the cathode; the stable combustion chamber L3 is connected to the compression chamber L2, It is a parabolic cavity with a diameter of 20-100mm, a length of 30-100mm, and a thickness of 5-20m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com