Single-conductor flexible high temperature heat tracing cable

A heating cable, flexible technology, applied in the field of cables, can solve the problems of difficult temperature adjustment and control, excessive energy consumption, poor flexibility, etc., and achieve the effects of easy construction and maintenance, high heating power, and small temperature difference across the length

Inactive Publication Date: 2012-04-25

JIANGSU XINYANG CABLE

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

And this kind of pipeline is generally outdoors. When the transported liquid is lower than a certain temperature, not only the viscosity is high, but sometimes it will solidify, so the problem of antifreeze and heat preservation is raised.

The antifreeze and heat preservation of short-distance pipelines can be protected by steam, but this method is not only labor-intensive and time-consuming, but also must be equipped with steam boilers, and the temperature is difficult to adjust and control; for long-distance pipelines, due to excessive energy consumption, this method The method is even more unworkable

In this case, heating cables have been widely used, but at present, the heating temperature of electric heating cables has great limitations, the service life is low and the flexibility is poor, and the construction is difficult

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

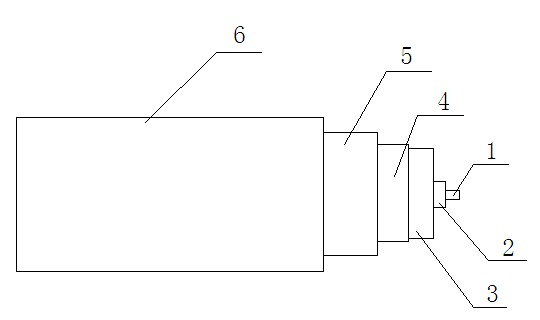

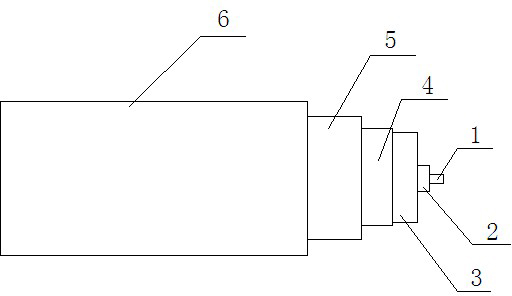

[0008] Such as figure 1 As shown, the present invention is provided with an insulated conductor, and a heating element 3, an inner sheath layer 4, a shielding layer 5 and an outer sheath layer 6 are sequentially arranged outside the insulated conductor; the insulated conductor includes a silver-plated copper wire 1, and the silver-plated copper wire 1 is wrapped with an insulating layer 2 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a single-conductor flexible high temperature heat tracing cable and relates to the technical field of a cable, in particular to a flexible high temperature heat tracing cable. The single-conductor flexible high temperature heat tracing cable comprises an insulated conductor. A heating body, an undersheath layer, a shielding layer and an outer sheath layer are sequentially arranged outside the insulated conductor. The insulated conductor comprises silver plated copper wires. An insulating layer is coated outside the silver plated copper wires. The single-conductor flexible high temperature heat tracing cable is uniform to emit heat, has ultralow full-length temperature difference, has low temperature resistance and high heating power, and is suitable for an industrial pipeline to convey crude oil, liquid industrial chemicals and industrial water.

Description

technical field [0001] The invention relates to the technical field of cables, in particular to a flexible high-temperature heating cable. Background technique [0002] With the development of industrial pipeline transportation technology, long-distance transportation of crude oil, liquefied chemical raw materials and industrial water has become more and more common. At the same time, pipeline transportation technology is used in power plants, kerosene plants, water treatment workshops and food processing departments to replace machinery Transportation, too, is becoming more and more popular. And this kind of pipeline is generally all outdoors, when the conveying liquid is lower than a certain temperature, not only the viscosity is higher, sometimes also solidify, so the problem of antifreeze and heat preservation has just been raised. The antifreeze and heat preservation of short-distance pipelines can be protected by steam, but this method is not only labor-intensive and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H05B3/56H05B3/10

CPCH05B2214/03

Inventor 葛广

Owner JIANGSU XINYANG CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com