Time-controlled intermittent life test method based on junction temperature real-time correction

A technology of life test and heating time, applied in semiconductor working life test, single semiconductor device test, instrument and other directions, can solve the problem of insufficient accuracy of intermittent life test, and achieve the effect of strict conditions and accurate test requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

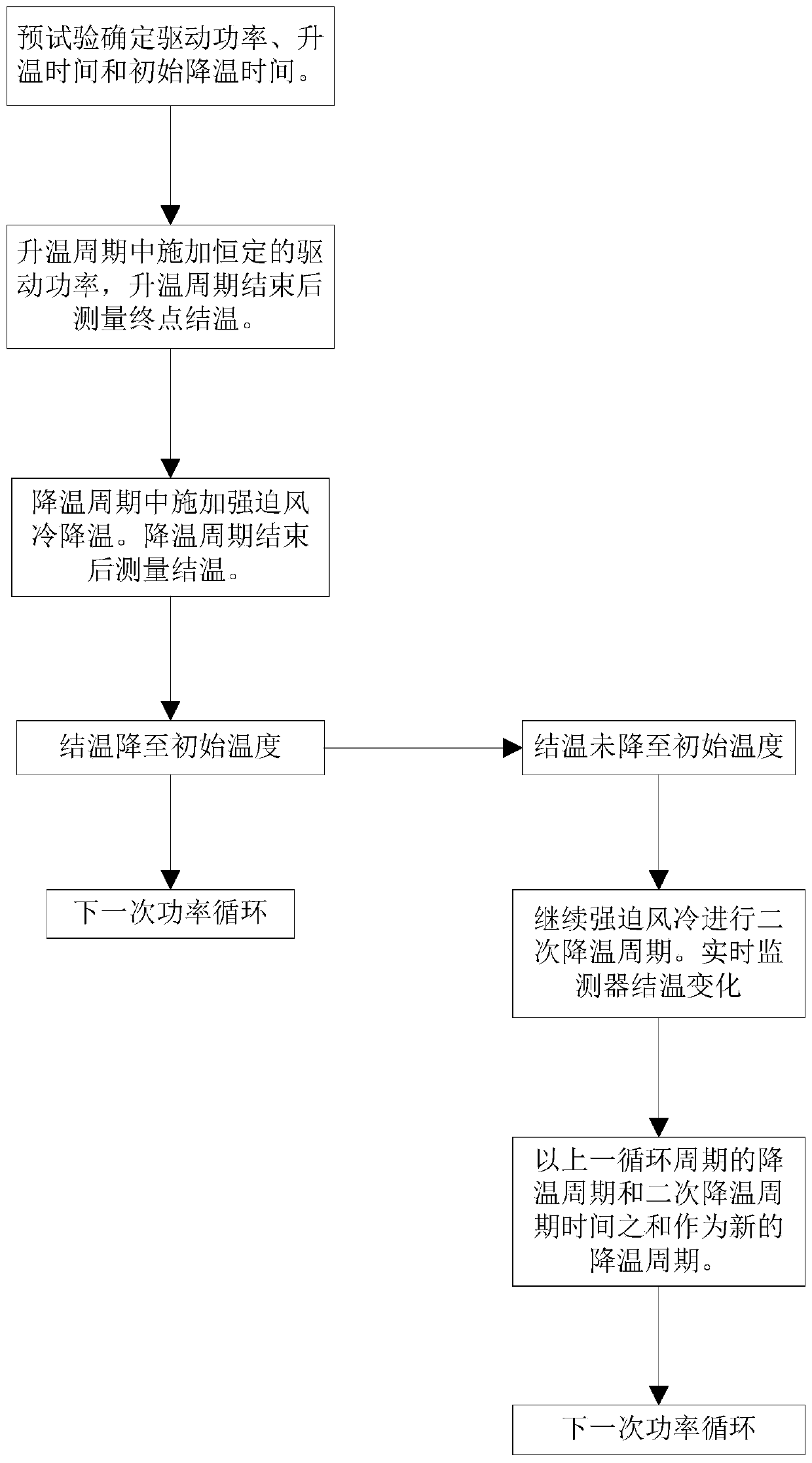

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] The implementation method of junction temperature monitoring in the test process of the present invention comprises the following contents:

[0025] This method needs to measure the junction temperature online during the test, and the influence of the measurement of the junction temperature on the test process should be minimized. Compared with the case temperature measurement, the junction temperature measurement cannot be directly carried out by external means such as thermocouples. In the implementation process of the present invention, it is necessary to use the indirect measurement of the junction temperature by monitoring the changes of temperature-sensitive electrical parameters.

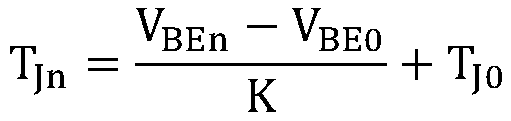

[0026] For the relationship between the temperature-sensitive electrical parameters of specific devices and the junction temperature, it is necessary to apply a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com