Heavy-duty engine deep thermal shock test device

A technology of cold and heat shock and test equipment, which is applied in the direction of engine testing, measuring equipment, machine/structural component testing, etc., to achieve the effects of shortening the test cycle, improving product life, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

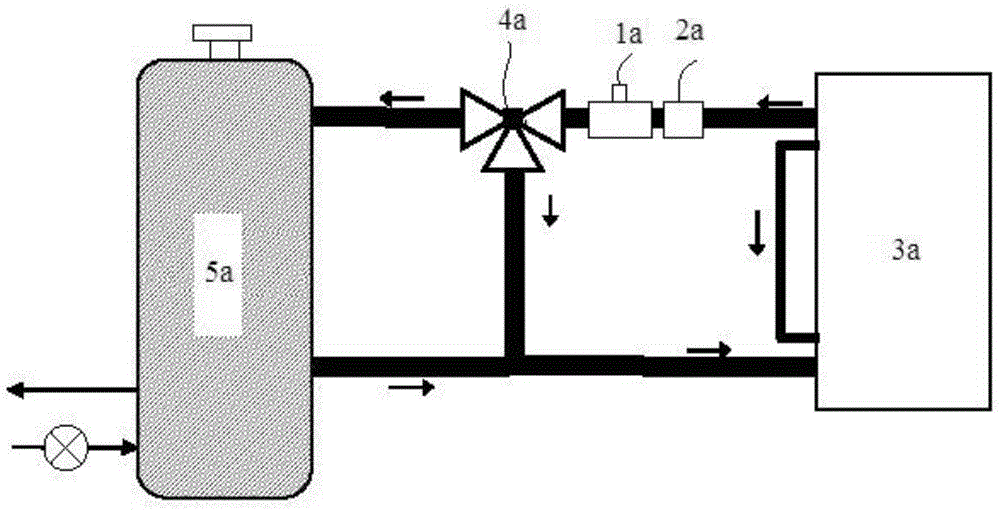

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

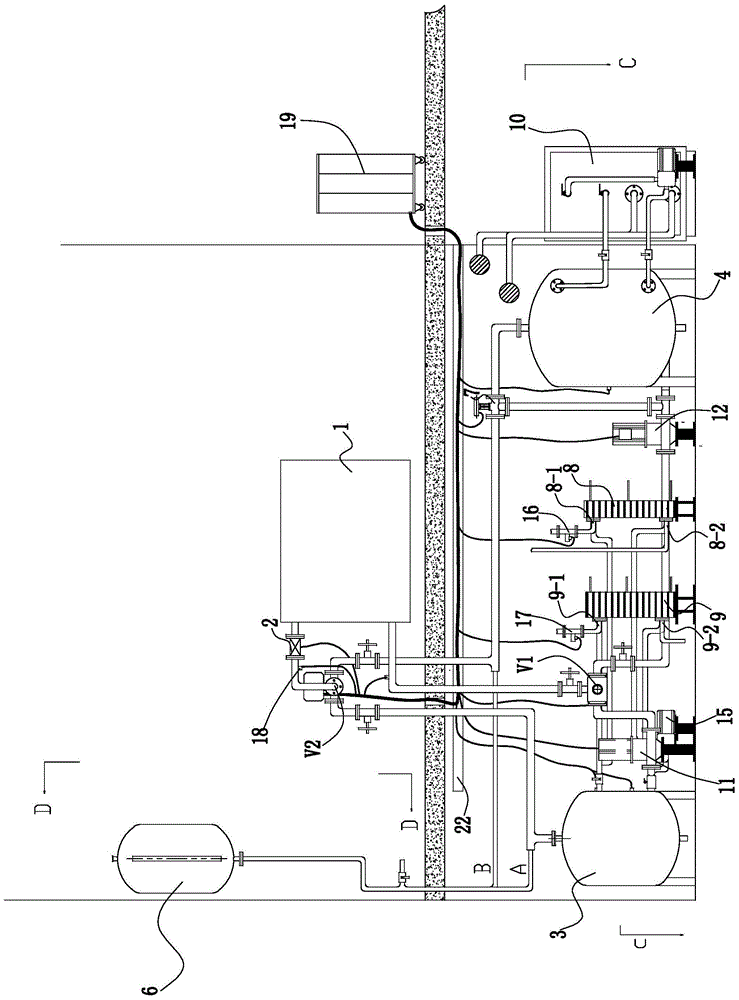

[0034] The present invention will be further described below in conjunction with specific drawings.

[0035] Such as Figure 2 to Figure 5 As shown: the heavy-duty engine deep cold and heat shock test device includes engine 1, electromagnetic flowmeter 2, hot water tank 3, cold water tank 4, cold expansion water tank 5, thermal expansion water tank 6, three-way proportional valve 7, hot water heat exchange Device 8, cooling water inlet 8-1, cooling water outlet 8-2, steam heat exchanger 9, steam inlet 9-1, steam outlet 9-2, refrigeration unit 10, first circulation pump 11, second circulation pump 12 , the third circulation pump 13, the fourth circulation pump 14, the fifth circulation pump 15, the first solenoid valve 16, the second solenoid valve 17, the engine outlet water temperature sensor 18, the thermal shock control cabinet 19, the air release port 20, and the air release valve 21. Electrical cable bridge 22, first switching valve V1, second switching valve V2, etc.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com