Water and oil repellency surface microstructure and manufacturing method thereof

A hydrophobic, oleophobic and microstructure technology, which is applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of poor performance repeatability, irregular micro-nano structure, poor uniformity, etc., and achieve flow resistance reduction, The effect of simple chemical treatment and high mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

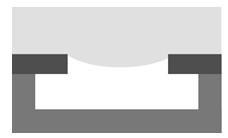

[0036] like figure 1 As shown, a hydrophobic and oleophobic surface microstructure includes a substrate and a T-shaped micro-nanostructure etched on the substrate. The T-shaped micro-nanostructure includes a vertical part 1 and a horizontal part 2, and the horizontal part 2 is arranged on the vertical part. 1 top, and the horizontal part 2 is aligned with the center of the vertical part 1. There is a strong enough bonding force between the horizontal part 2 and the vertical part 1 to maintain a stable mechanical strength. The cross-sectional area of the horizontal part 2 is larger than that of the vertical part 1, and the diameter of the horizontal part 2 is less than 50um. The T-shaped micro-nanostructures are arranged in an array, and the distance between adjacent T-shaped micro-nanostructures is no more than 15 times the diameter of the transverse part 2 .

[0037] like figure 2 and 3 As shown, the T-shaped micro-nanostructure can make use of the wetting properties o...

Embodiment 2

[0040] This embodiment is except following feature, and other is all identical with embodiment 1:

[0041] like Figure 5 The process steps shown are as follows: first, the surface is treated with substrate cleaning and mask pattern transfer process, and SiO with a thickness of 100nm-200nm is thermally grown. 2 thin-film silicon substrate; then, using CF 4 or CHF 3 Gas plasma etching and etching of SiO with photoresist as a mask 2 thin film until the silicon surface is exposed; then, the photoresist is washed off with stripper or acetone, and subjected to O 2plasma cleaning; furthermore, using XeF 2 The silicon surface is treated by a vapor phase etching process; finally, the XeF 2 The silicon surface treated by vapor phase etching process is obtained as Figure 9 The hydrophobic and oleophobic surface microstructure shown.

Embodiment 3

[0043] This embodiment is except following feature, and other is all identical with embodiment 1:

[0044] Such as Figure 6 The process steps shown are as follows: first, the surface is treated with substrate cleaning and mask pattern transfer process, and SiO with a thickness of 100nm-200nm is thermally grown. 2 thin-film silicon substrate; then, using CF 4 or CHF 3 Gas plasma etching and etching of SiO with photoresist as a mask 2 thin film until the silicon surface is exposed; then, the photoresist is washed off with stripper or acetone, and subjected to O 2 Plasma cleaning; moreover, using DRIE etching process to process the silicon surface; finally, using CVD chemical vapor deposition process to process the silicon surface treated by DRIE etching process, to obtain the following Figure 10 The hydrophobic and oleophobic surface microstructure shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com