Biomass combustion equipment with double fire grates

A biomass and double grate technology, which is applied in combustion equipment, solid fuel combustion, lighting and heating equipment, etc., can solve the problems of prohibitive fuel costs, etc., and achieve easy control and organization of combustion, clean operation site, and avoid thermal deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The principle, specific structure and best implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

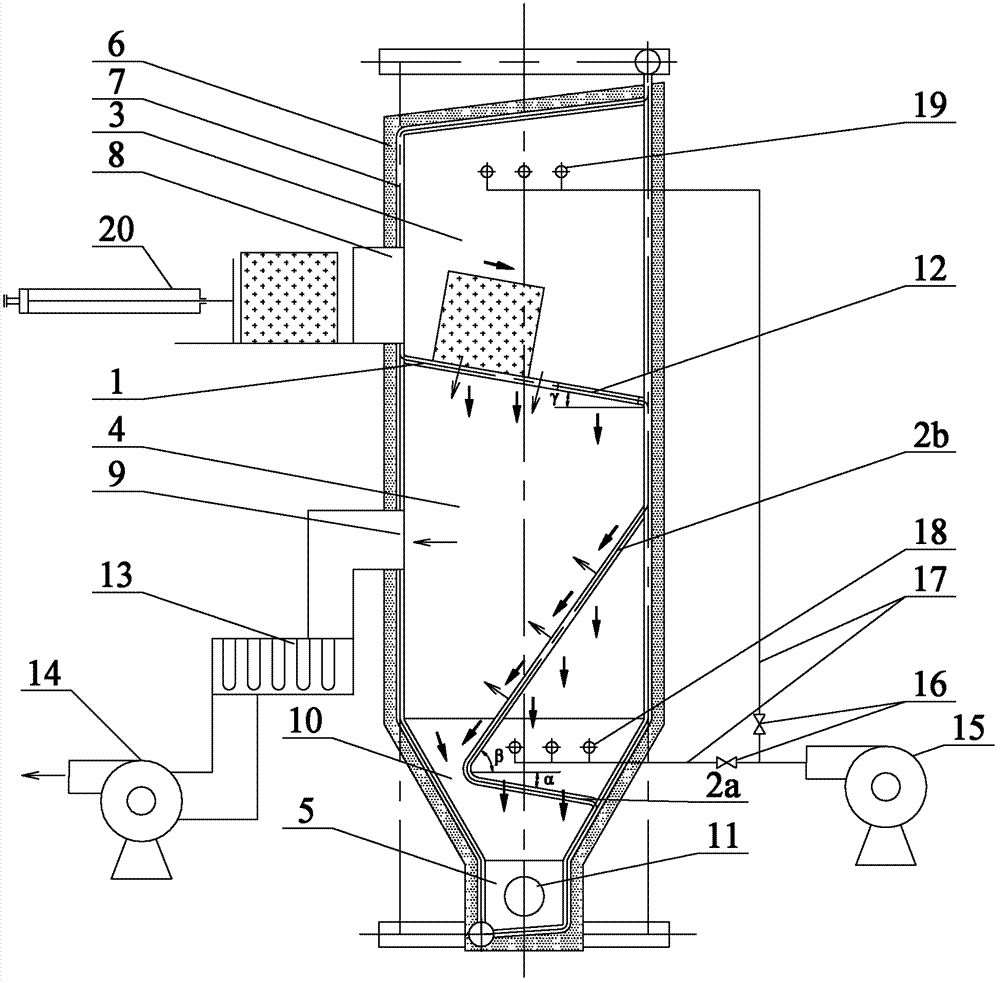

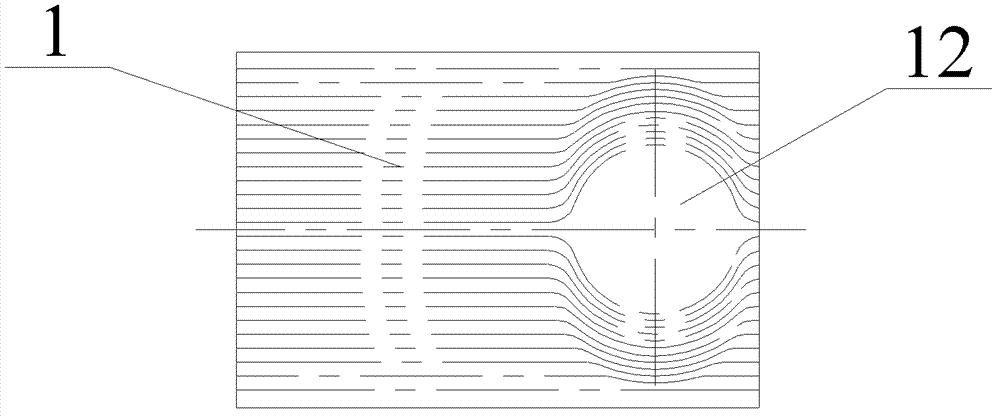

[0014] figure 1 It is a structural schematic diagram of the present invention, which includes a feeding device, a feed inlet 8, a flue gas outlet 9, a furnace wall 6, a water wall 7, a combustion chamber and a fire grate arranged in the combustion chamber. The feeding device is a piston pusher 20, which is used to send the bulk biomass package into the main combustion chamber 3 through the feed port 8. The grate is composed of the upper grate 1 and the lower grate. The upper grate 1 and the lower grate divide the combustion chamber into the main combustion chamber 3 and the auxiliary combustion chamber 4. The lower part of the auxiliary combustion chamber 4 is a contraction section, and the contraction of the auxiliary combustion chamber 4 The lower part of the section is provided with an ash chamber 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com