Method for producing organic fertilizer by polyoxin residue

A polyantimycin and organic fertilizer technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of difficult antibiotic residue treatment, difficult popularization and application, long treatment time, etc., to improve crop quality, increase crop yield, The effect of short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

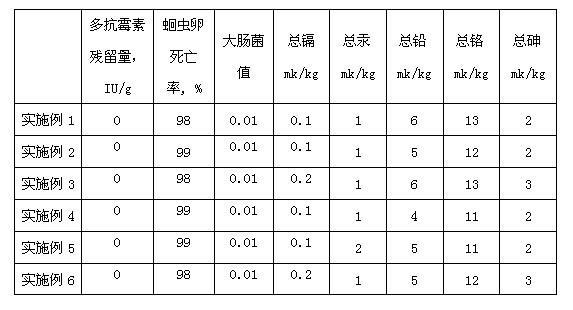

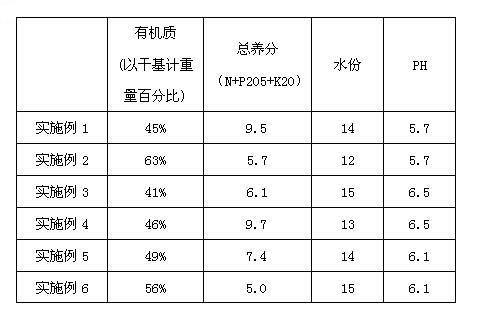

Embodiment 1

[0025] Filter the polyoxin fermentation broth with a plate frame to obtain 100 kg of massive polyoxin residue with a water content of 60-70% by weight, treat it in a pressure vessel with a temperature of 120 ° C and a saturated vapor pressure of 0.100 MPa for 30 minutes, add Mix 6 kg of potassium dihydrogen phosphate and 15 kg of diatomaceous earth evenly, then adjust the pH value to 5.7 with 1.9 kg of borax, and then dry the above mixture by exposure to the sun or other conventional methods. The mixture is dried until the water content is 18%, extruded and granulated, the hole diameter of the template is 3.0 mm, cooled, screened, tested, and packaged to obtain the granular organic fertilizer.

Embodiment 2

[0027] Filter the polyoxin fermentation broth with a plate frame to obtain 100 kg of massive polyoxin residue with a water content of 60-70% by weight, treat it in a pressure vessel with a temperature of 120 ° C and a saturated vapor pressure of 0.100 MPa for 30 minutes, add Mix 2 kg of potassium dihydrogen phosphate and 1 kg of bentonite evenly, then adjust the pH value to 5.7 with 1.7 kg of borax, and then dry the above mixture by exposure to the sun or other conventional methods. The mixture is dried until the water content is 13%, then pulverized, cooled, tested, and packaged to obtain a powdered organic fertilizer.

Embodiment 3

[0029] Filter the polyoxin fermentation broth with a plate frame to obtain 100 kg of massive polyoxin residue with a water content of 60-70% by weight, treat it in a pressure vessel with a temperature of 130.5 ° C and a saturated vapor pressure of 0.175 MPa for 20 minutes, add Mix 4 kg of potassium dihydrogen phosphate and 20 kg of diatomaceous earth evenly, then adjust the pH value to 6.5 with 5.1 kg of borax, and then dry the above mixture by exposure to the sun or other conventional methods. The mixture is dried until the water content is 20%, extruded and granulated, the hole diameter of the template is 3.3mm, cooled, screened, tested, and packaged to obtain the granular organic fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com