Imitated silk fabric reactive printing method

A technology of reactive printing and imitation silk, applied in the field of textile printing and dyeing, can solve the problems of low product quality, increased equipment loss, use restrictions, etc., and achieve the effect of soft and drapey, bright colors and rich layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

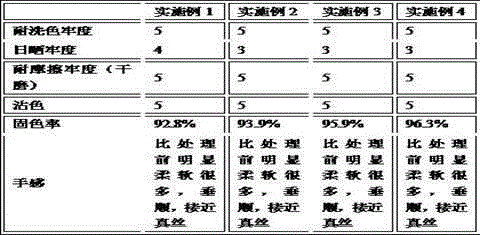

Examples

Embodiment 1

[0037] A method for imitation silk active printing, the steps are as follows:

[0038] (1) Fabric pretreatment: Put the imitation silk cloth into the pretreatment agent for pretreatment

[0039] Pretreatment agent is made up of the raw material of following parts by weight:

[0040] Trehalose 1 part

[0041] Collagen 1.5 parts

[0042] 50 parts of water

[0043] (2) Sizing: The pretreated imitation silk cloth is sizing on a sizing machine, and the sizing is composed of the following raw materials in parts by weight:

[0044] Phosphate grafted starch 0.5 parts

[0045] 4 parts sodium alginate

[0046] Nano titanium dioxide 1 part

[0047] Baking soda 3 parts

[0048] Yuan Mingfen 2 parts

[0049] 4 parts urea

[0050] Triethylene glycol 1 part

[0051] 40 parts of water

[0052] Mix the above components and put them into a beater, beat until the slurry is uniform, and then let it stand for 2 hours;

[0053] (3) Heating and shaping: Two hot blankets are pressed and h...

Embodiment 2

[0058] A method for imitation silk active printing, the steps are as follows:

[0059] (1) Fabric pretreatment: Put the imitation silk cloth into the pretreatment agent for pretreatment

[0060] Pretreatment agent is made up of the raw material of following parts by weight:

[0061] Trehalose 2 parts

[0062] Collagen 1 part

[0063] 60 parts of water

[0064] (2) Sizing: The pretreated imitation silk cloth is sizing on a sizing machine, and the sizing is composed of the following raw materials in parts by weight:

[0065] Phosphate grafted starch 1.5 parts

[0066] 3 parts sodium alginate

[0067] Nano titanium dioxide 1.5 parts

[0068] Baking soda 2 parts

[0069] Yuan Mingfen 3 parts

[0070] 3 parts urea

[0071] Triethylene glycol 1 part

[0072] 50 parts of water;

[0073] Mix the above components and put them into a beater, beat until the slurry is uniform, and then let it stand for 2 hours;

[0074] (3) Heating and shaping: Two hot blankets are pressed and...

Embodiment 3

[0079] A method for imitation silk active printing, the steps are as follows:

[0080] (1) Fabric pretreatment: Put the imitation silk cloth into the pretreatment agent for pretreatment

[0081] Pretreatment agent is made up of the raw material of following parts by weight:

[0082] Trehalose 1 part

[0083] Collagen 1.4 parts

[0084] 55 parts of water

[0085] (2) Sizing: The pretreated imitation silk cloth is sizing on a sizing machine, and the sizing is composed of the following raw materials in parts by weight:

[0086] Phosphate grafted starch 0.7 part

[0087] 4 parts sodium alginate

[0088] Nano titanium dioxide 1.1 parts

[0089] Baking soda 3 parts

[0090] Yuan Mingfen 2 parts

[0091] 4 parts urea

[0092] Triethylene glycol 1 part

[0093] 42 parts of water

[0094] Mix the above components and put them into a beater, beat until the slurry is uniform, and then let it stand for 2 hours;

[0095] (3) Heating and shaping: Two hot blankets are pressed and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com