Low voltage varistor ceramic material and preparation method thereof

A ceramic material and varistor technology, applied in the field of piezoelectric ceramic materials, can solve the problems of unsuitable low-voltage varistor ceramics and high potential gradient, and achieve the effects of reducing energy consumption, reducing potential gradient and improving nonlinear coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

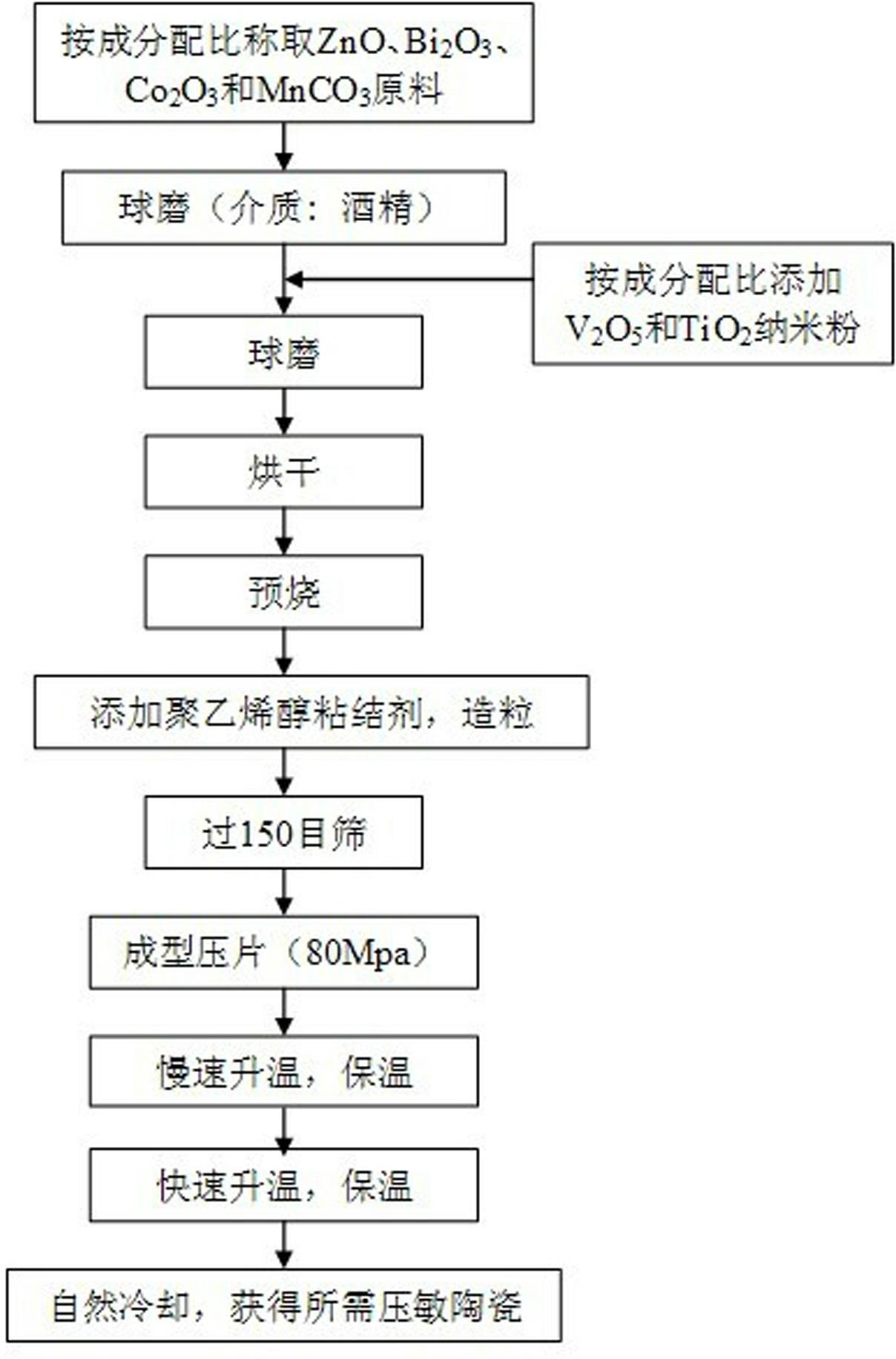

Method used

Image

Examples

Embodiment 1

[0021] (1) Use the following raw material components and their content to prepare materials:

[0022] V 2 o 5 0.06 mol, 10.913 g

[0023] TiO 2 1.10 moles, 87.888 grams

[0024] ZnO 96.666 moles, 7866.582 grams

[0025] Bi 2 o 3 0.692 moles, 322.442 grams

[0026] co 2 o 3 0.988 moles, 163.873 grams

[0027] MnCO 3 0.494 mol, 56.783 g

[0028] where: V 2 o 5 : TiO 2 : ZnO-Bi 2 o 3 The molar ratio of the base is 0.06: 1.10: 98.84; ZnO-Bi 2 o 3 Basic composition ZnO: Bi 2 o 3 :Co 2 o 3 : MnCO 3 The molar ratio is 97.8 0 : 0.70 : 1.00 : 0.50.

[0029](2) Using absolute ethanol as solvent, the weighed ZnO, Bi 2 o 3 、Co 2 o 3 and MnCO 3 After the raw materials are mixed, ball mill at a rate of 280r / min for 13h in a ball mill, add V 2 o 5 and TiO 2 Then ball mill for 11h, take it out and bake at 100°C for 10h;

[0030] (3) The final powder after ball milling is...

Embodiment 2

[0036] (1) Use the following raw material components and their content to prepare materials:

[0037] V 2 o 5 0.07 mol, 12.731 g

[0038] TiO 2 1.00 moles, 79.898 grams

[0039] ZnO 96.951 moles, 7889.775 grams

[0040] Bi 2 o 3 0.594 moles, 276.778 grams

[0041] co 2 o 3 0.989 moles, 164.039 grams

[0042] MnCO 3 0.396 mol, 45.519 g

[0043] where: V 2 o 5 : TiO 2 : ZnO-Bi 2 o 3 The molar ratio of the base is 0.07: 1.00: 98.93; ZnO-Bi 2 o 3 Basic composition ZnO: Bi 2 o 3 :Co 2 o 3 : MnCO 3 The molar ratio is 98.00:0.60:1.00:0.4.

[0044] (2) Using absolute ethanol as solvent, the weighed ZnO, Bi 2 o 3 、Co 2 o 3 and MnCO 3 After the raw materials are mixed, ball mill at a rate of 260r / min for 14h in a ball mill, add V 2 o 5 and TiO 2 Then ball mill for 12 hours, take it out and bake at 120°C for 8 hours;

[0045] (3) The final powder after ball milling is p...

Embodiment 3

[0051] (1) Use the following raw material components and their content to prepare materials:

[0052] V 2 o 5 0.08 mol, 14.550 g

[0053] TiO 2 1.20 moles, 95.878 grams

[0054] ZnO 96.449 moles, 7848.923 grams

[0055] Bi 2 o 3 0.691 moles, 321.976 grams

[0056] co 2 o 3 1.086 moles, 180.127 grams

[0057] MnCO 3 0.494 mol, 56.783 g

[0058] where: V 2 o 5 : TiO 2 : ZnO-Bi 2 o 3 The molar ratio of the base is 0.08: 1.20: 98.72; ZnO-Bi 2 o 3 Basic composition ZnO: Bi 2 o 3 :Co 2 o 3 : MnCO 3 The molar ratio is 97.70:0.70:1.10:0.50.

[0059] (2) Using absolute ethanol as solvent, the weighed ZnO, Bi 2 o 3 、Co 2 o 3 and MnCO 3 After the raw materials are mixed, ball mill at a rate of 300r / min for 12h in a ball mill, add V 2 o 5 and TiO 2 Then ball mill for 10 hours, take it out and bake at 110°C for 9 hours;

[0060] (3) The final powder after ball milling i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com