High-performance concrete extrusion partition plate and its preparation method

A high-performance concrete and partition board technology, which is applied in the field of building materials, can solve the problems of cracks between partition boards and partition boards, poor bending resistance, and poor water resistance of partition boards, so as to eliminate yellowing and Falling off phenomenon, high compressive strength, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

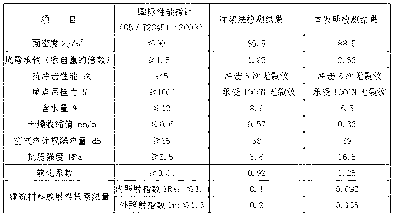

Method used

Image

Examples

Embodiment 1

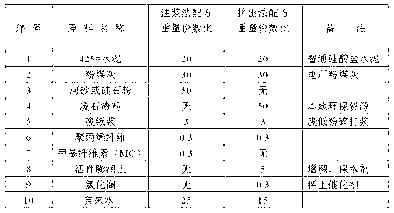

[0035] A high-performance concrete extruded partition wall board is made of the following components according to the ratio of parts by weight:

[0036] 200 parts of cement; 200 parts of fly ash;

[0037] 400 parts of waste rock powder; 3 parts of polypropylene fiber;

[0038] 30 parts of plant fiber; 60 parts of inorganic water retaining agent;

[0039] 2 parts of rare earth catalyst; 150 parts of tap water.

[0040] Wherein, the cement is Portland cement with a label of 42.5R; the fly ash is the first-grade fly ash produced by a coal-fired thermal power plant; the waste rock powder is stone powder crushed from waste rock slag to 80 mesh; The plant fiber is waste paper pulp; the inorganic water-retaining agent is activated bentonite, and the activated bentonite is made from the following raw materials in weight percentage:

[0041] Bentonite 75%; Retarding superplasticizer 20%;

[0042] Sodium dodecylbenzenesulfonate 8%;

[0043] The above raw materials are sequentially ...

Embodiment 2

[0050] A high-performance concrete extruded partition wall board is made of the following components according to the ratio of parts by weight:

[0051] 300 parts of cement; 350 parts of fly ash;

[0052] 600 parts of waste rock powder; 5 parts of polypropylene fiber;

[0053] 50 parts of plant fiber; 80 parts of inorganic water retaining agent;

[0054] 3 parts of rare earth catalyst; 200 parts of tap water.

[0055]Wherein, the cement is Portland cement with a label of 42.5R; the fly ash is first-grade fly ash produced by a coal-fired thermal power plant; the waste rock powder is stone powder crushed from waste rock slag to 200 mesh; The plant fiber is waste paper pulp; the inorganic water-retaining agent is activated bentonite, and the activated bentonite is made from the following raw materials in weight percentage:

[0056] Bentonite 85%; Retarding superplasticizer 10%;

[0057] Sodium dodecylbenzenesulfonate 2%;

[0058] The above raw materials are sequentially adde...

Embodiment 3

[0065] A high-performance concrete extruded partition wall board is made of the following components according to the ratio of parts by weight:

[0066] 250 parts of cement; 275 parts of fly ash;

[0067] 500 parts of waste rock powder; 4 parts of polypropylene fiber;

[0068] 40 parts of plant fiber; 70 parts of inorganic water retaining agent;

[0069] 2.5 parts of rare earth catalyst; 175 parts of tap water.

[0070] Wherein, the cement is Portland cement with a label of 42.5R; the fly ash is the first-grade fly ash produced by a coal-fired thermal power plant; the waste rock powder is stone powder crushed from waste rock slag to 140 mesh; The plant fiber is waste paper pulp; the inorganic water-retaining agent is activated bentonite, and the activated bentonite is made from the following raw materials in weight percentage:

[0071] 80% bentonite; 15% retarded superplasticizer;

[0072] Sodium dodecylbenzenesulfonate 5%;

[0073] The above raw materials are sequentiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com