Method for manufacturing decorative components

A technology for decorative elements and components, which is applied to household components, applications, household appliances, etc., can solve the problems of uneven vibration behavior, unfavorable visual surface of decorative components, and influence, and achieves the effect of reducing production time and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

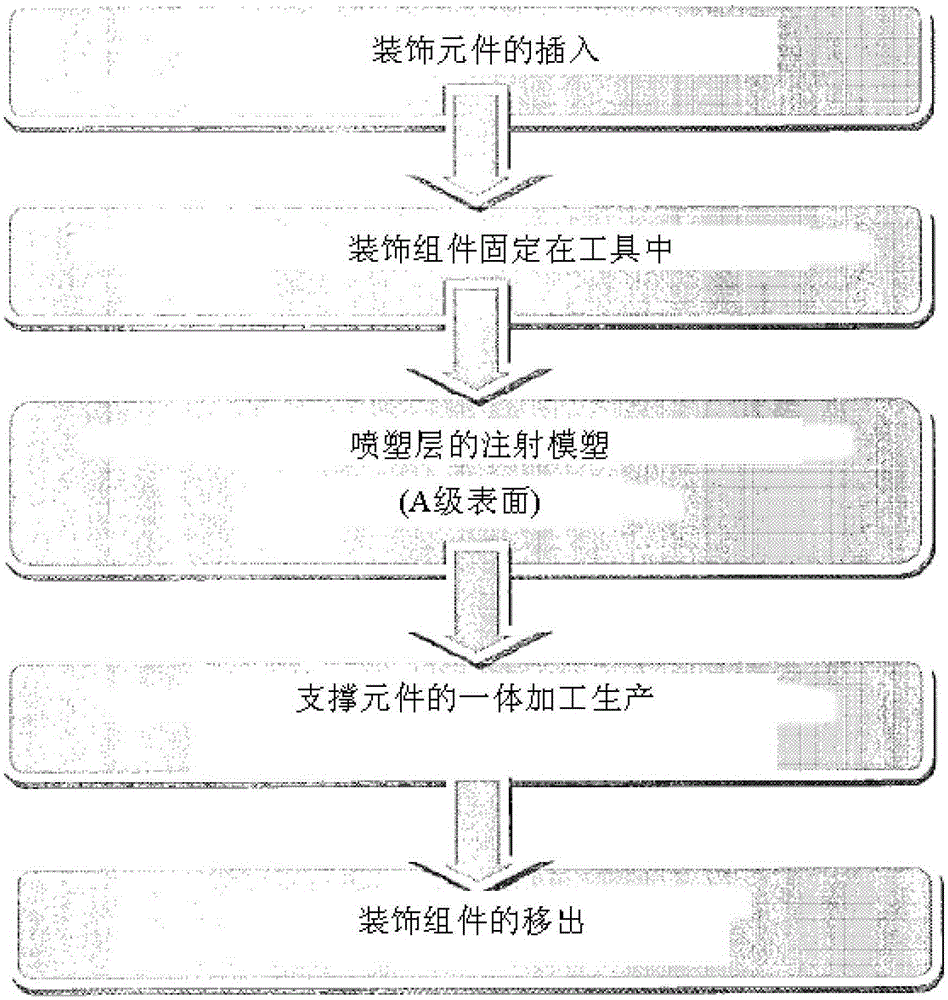

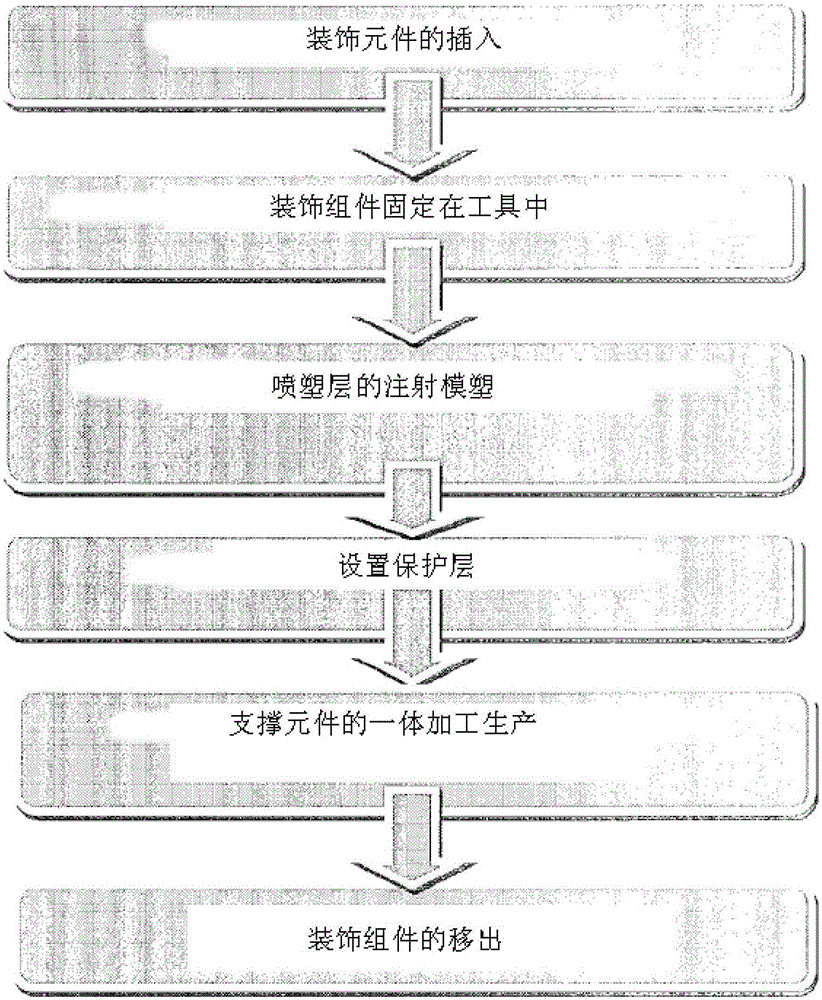

[0023] figure 1 and 2 represents the method steps according to the invention. according to figure 1 The first method step, step 1 inserts the decorative element into the injection mold, step 2 fixes the decorative element in the injection mold, and does not displace during the injection molding process, step 3, encapsulates the decorative element as a whole by injection molding In the plastic sprayed material, a completely closed plastic coated layer is created around the decorative element. according to figure 1 In the method, the plastic sprayed layer forms a continuous outer layer which, when unfinished, forms the visible face of the trim component. In step 4, without changing the position of the decorative element in the mold, the supporting element is directly cast on the back of the decorative element surrounded by the sprayed plastic layer through integral processing. The plastic-sprayed layer increases the rigidity of the decorative element, so that no thermal def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com