Method for producing LOW-E glass by means of vacuum magnetron sputtering

A vacuum magnetron sputtering, glass technology, applied in chemical instruments and methods, glass/slag layered products, layered products, etc. Greening and other problems, to achieve the effect of reducing thickness and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

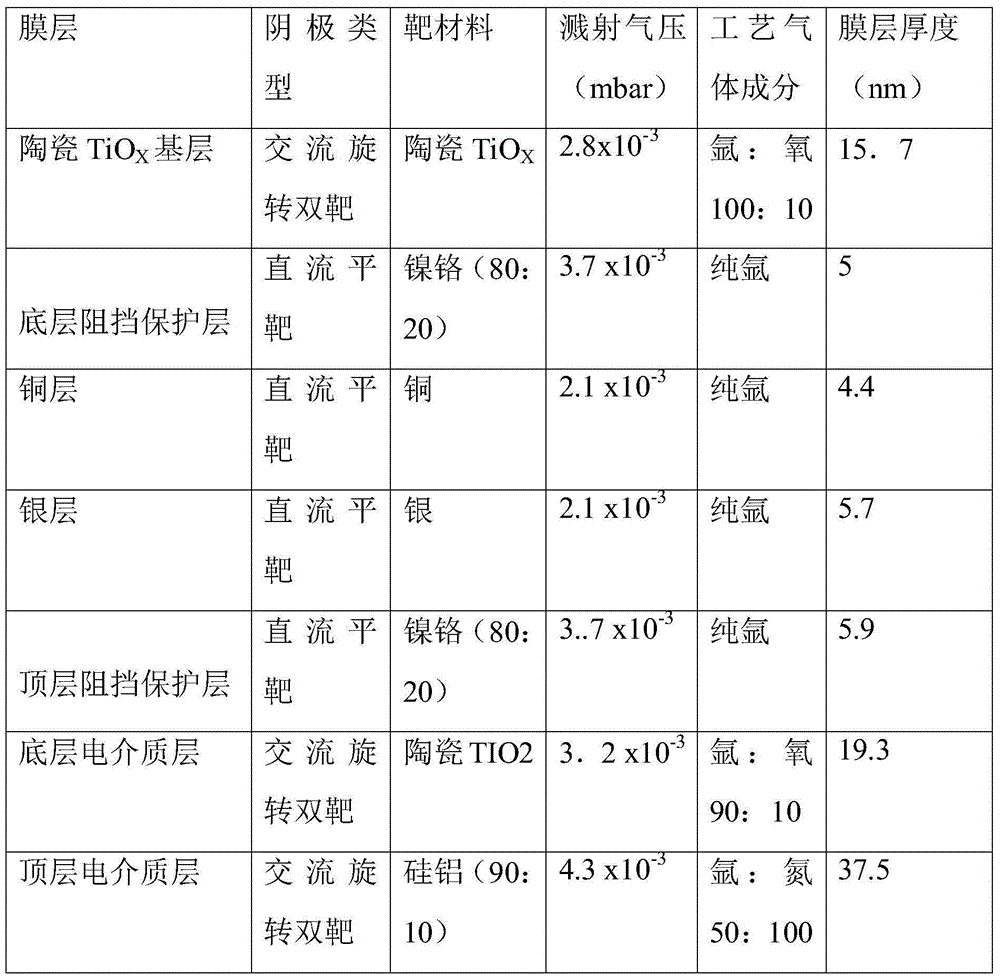

[0040] Table 1 Target position distribution and coating process parameters of coated glass in this embodiment

[0041]

[0042] The optical properties of the LOW-E glass produced by the method of the present embodiment are as follows:

[0043] Visible light transmittance T=60.1﹪; visible light glass surface reflectance 11.5﹪; visible light glass surface color coordinate a*=-2.2; visible light glass surface color coordinate b*=-7.2; visible light transmission color coordinate a*=-0.44; visible light transmission Pass color coordinate b*=-1.17.

Embodiment 2

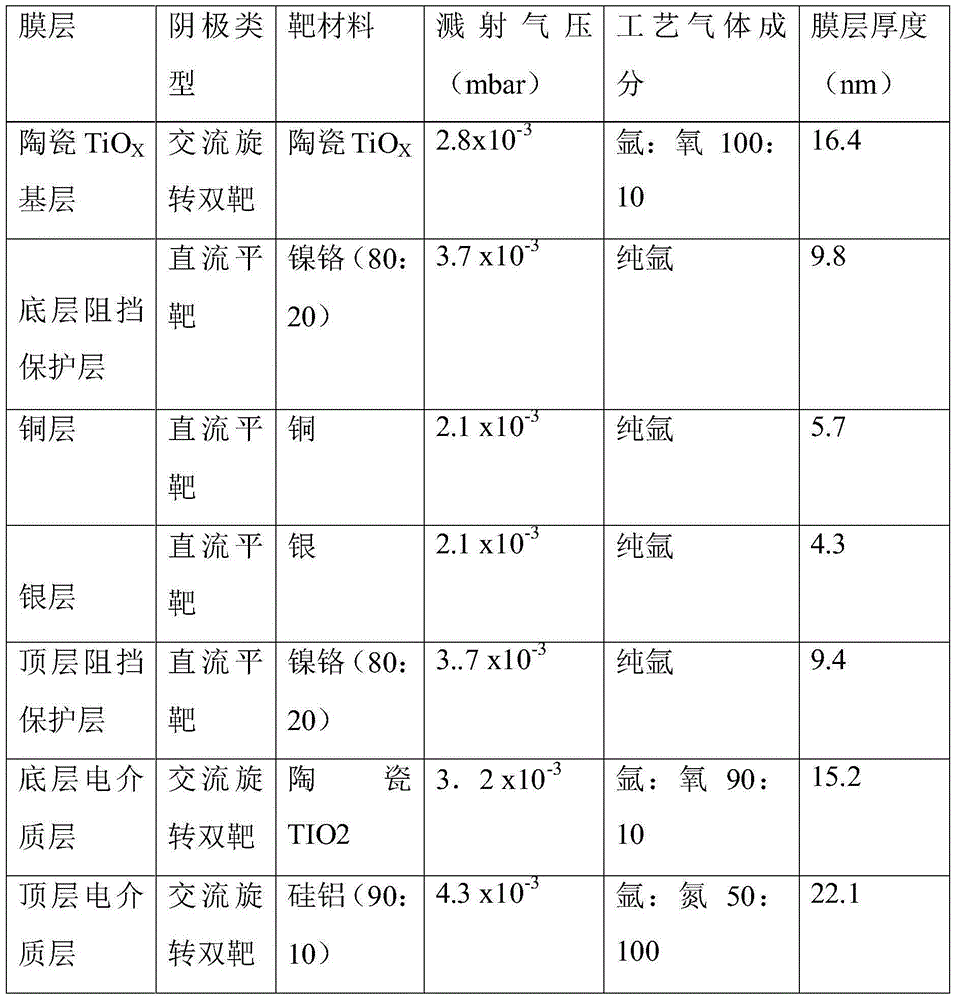

[0045] Table 2 is the target position distribution and coating process parameters of the coating glass of this embodiment

[0046]

[0047]The optical properties of the LOW-E glass produced by the method of the present embodiment are as follows:

[0048] Visible light transmittance T=51.5﹪; visible light glass surface reflectance 18.15﹪; visible light glass surface color coordinate a*=-3.05; visible light glass surface color coordinate b*=-2.95; visible light transmission color coordinate a*=-1.04; visible light transmission Pass color coordinate b*=-1.06.

Embodiment 3

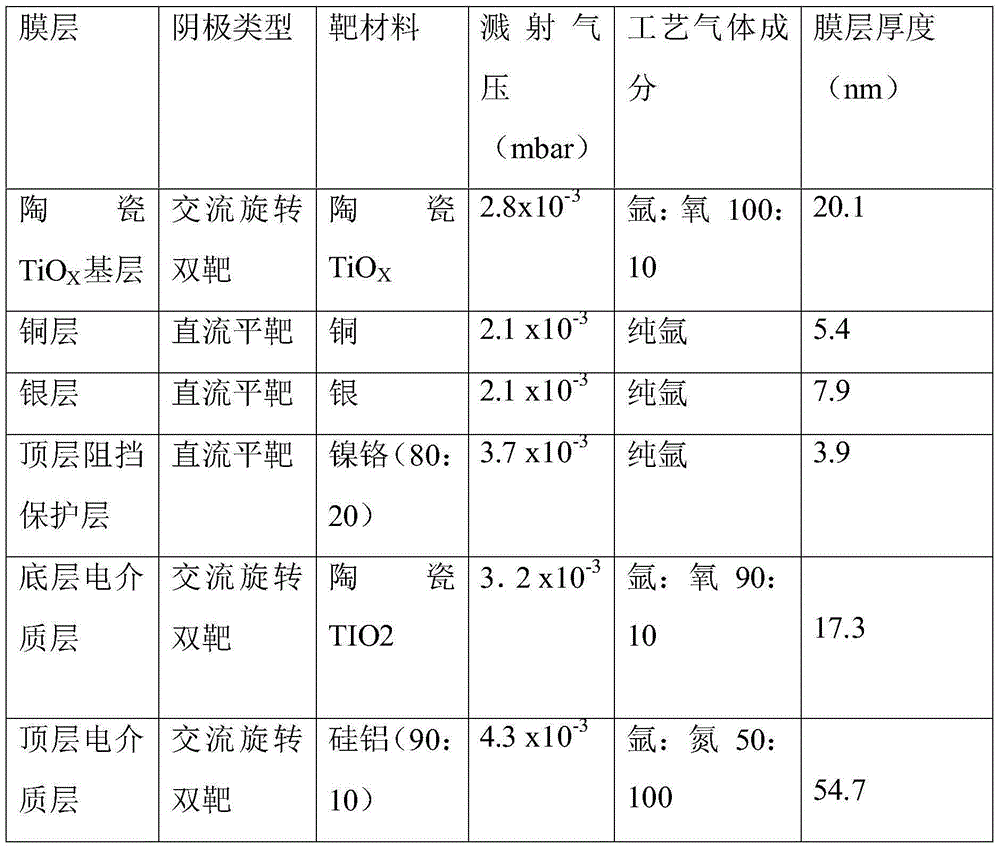

[0050] Table 3 is the target position distribution and process parameters of the coated glass of this embodiment

[0051]

[0052] The optical properties of the LOW-E glass produced by the method of the present embodiment are as follows:

[0053] Visible light transmittance T=64.8﹪; visible light glass surface reflectance 11.35﹪; visible light glass surface color coordinate a*=-2.10; visible light glass surface color coordinate b*=-4.04; visible light transmission color coordinate a*=-0.19; visible light transmission The passing color coordinate b*=0.62.

[0054] To sum up, the Low-E glass produced by this method eliminates the problem of green and yellowish outdoor reflection colors due to the greenish color of the glass substrate, and also greatly improves the refractive index of the Low-E glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com