Production method for high-grade non-oriented silicon steel

A technology of oriented silicon steel and production method, which is applied in the field of non-oriented electrical steel manufacturing, can solve the problems of steel plate being too brittle, cold rolling performance deterioration, and yield reduction, etc., to reduce surface oxidation, improve cold rolling performance, and coarse grain Effect

Inactive Publication Date: 2012-04-18

武汉钢铁有限公司

View PDF6 Cites 33 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The purpose of the present invention is to solve the problem existing in the prior art that because the hot-rolled plate is too thin, the hot-rolled rolling pressure increases, the shape of the hot-rolled plate is difficult to ensure, and the normalization temperature or intermediate annealing temperature is too high, causing the steel plate to be too brittle and cold-rolled. Deterioration of performance, reduction of yield, surface oxidation of steel plate due to high annealing temperature of the finished product, easy nodulation of hearth rolls, etc., to provide a kind of non-oriented silicon steel with good cold rolling performance, extremely low loss of high grade, and high process reliability Production method of high-grade non-oriented silicon steel

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0033] The present invention is further described below:

[0034] Table 1 is a list of steel grade compositions and weight percent values of various embodiments of the present invention;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

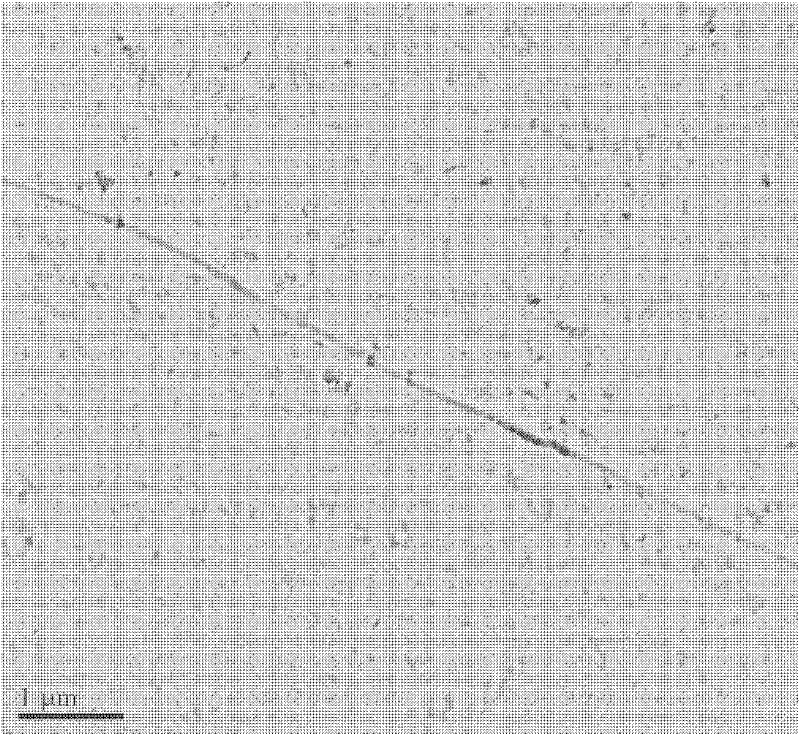

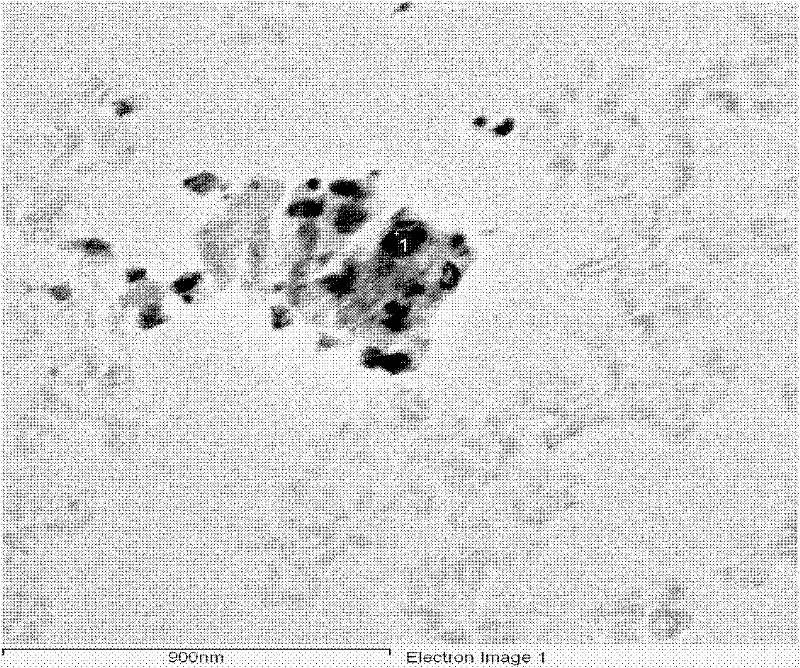

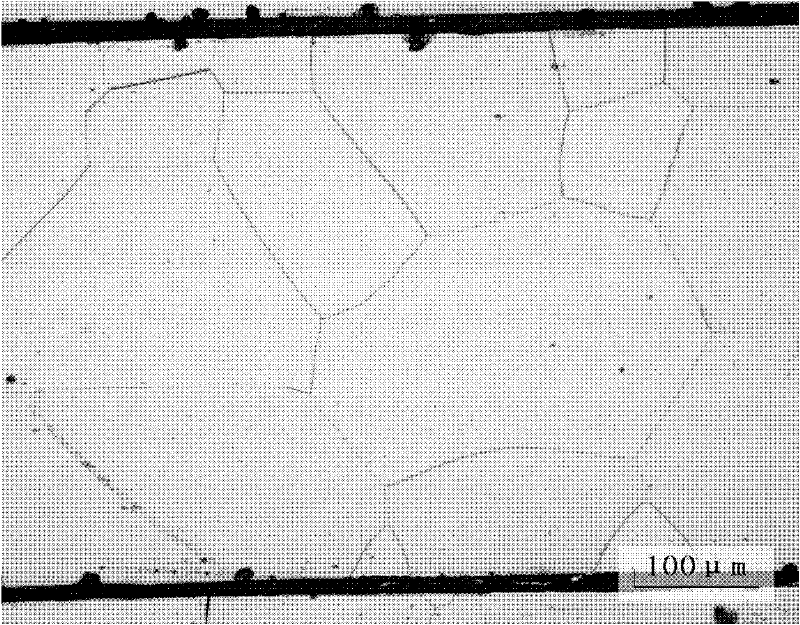

The invention relates to a manufacturing method for non-oriented electric steel. The method comprises the following steps of: smelting according to a clean steel process and continuously casting into billets; heating the continuous casting billets; performing hot rolling; reeling; naturally cooling to room temperature; normalizing; performing acid washing conventionally; performing cold rolling for the first time; performing intermediate annealing in the total hydrogen atmosphere or the mixed atmosphere of hydrogen and nitrogen; performing cold rolling for the second time; performing final annealing; and cooling conventionally, coating and finishing for later use. The finished product silicon steel with coarse grains and good texture can be obtained by adopting lower process heat treatment temperature; brittleness of the steel is reduced and cold rolling performance of a steel plate is improved by adopting lower normalizing temperature and intermediate annealing temperature; the problems of surface oxidation of the steel plate, nodulation of a furnace bottom roller and the like can be effectively solved by adopting lower finished product annealing temperature; and the high-grade non-oriented silicon steel with lower iron loss can be produced stably.

Description

technical field [0001] The invention relates to a method for manufacturing non-oriented electrical steel, in particular to a method for producing high-grade non-oriented silicon steel. Background technique [0002] Non-oriented electrical steel is widely used as core material for motors and transformers. In recent years, from the viewpoint of energy saving, there has been a strong demand for improvement in the efficiency of various electric appliances, and lower iron loss is desired as core materials for motors and transformers used in these electric appliances. [0003] As a means to reduce the loss of non-oriented electrical steel, we know that the resistivity of the steel plate can be increased by increasing the content of alloying elements such as Si and Al. However, when the current non-oriented silicon steel reaches the highest level, the brittleness of the steel plate will be increased on the basis of the existing Si and Al content, and the cold rolling performance o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/04C22C38/02C22C33/04C21D8/12

Inventor 詹东方李准黄璞周雅琴

Owner 武汉钢铁有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com