Screening of new strain capable of producing camptothecin and method for preparing camptothecin

A technology of camptothecin and bacterial strains, which is applied in the field of preparing camptothecin, can solve the problems of long synthetic route, high cost, and low extraction yield, achieve the effects of mild reaction conditions, solve the problem of drug source, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

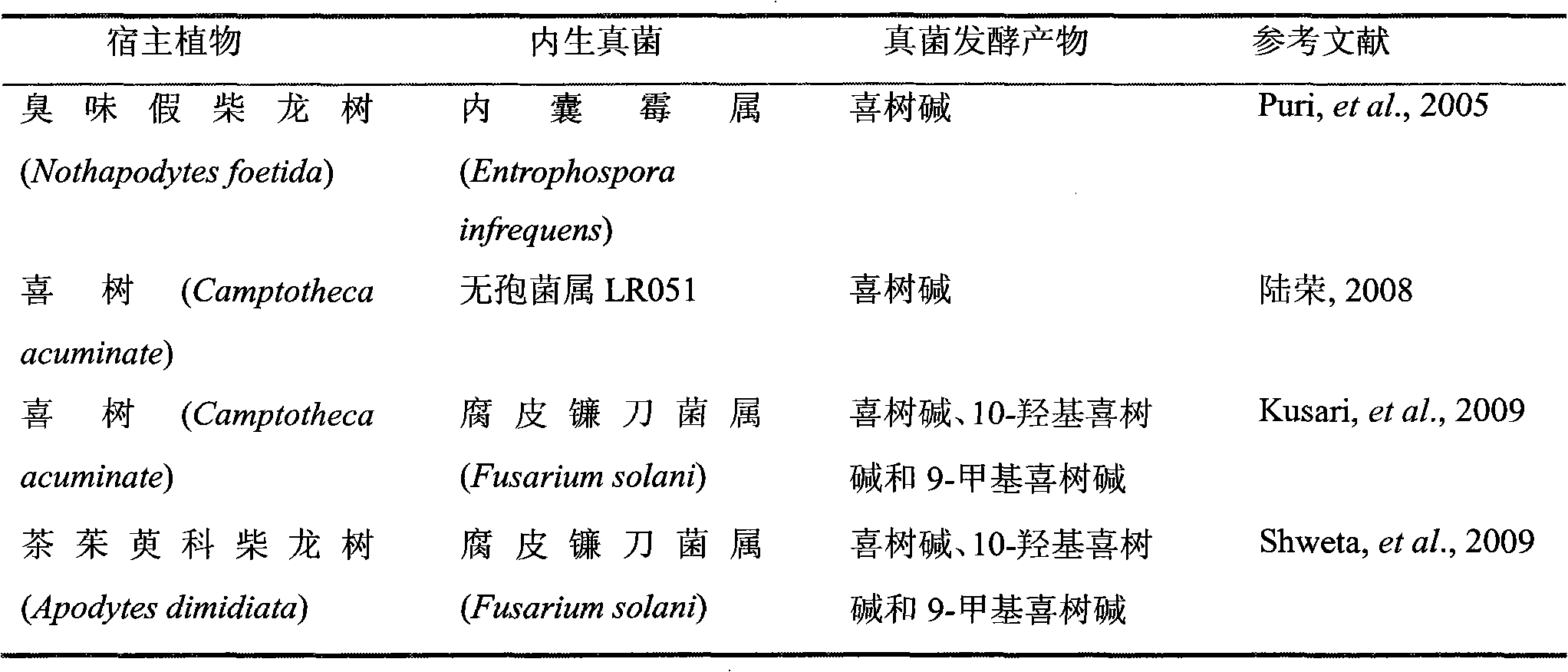

Method used

Image

Examples

Embodiment 1

[0022] Screen the new bacterial species producing camptothecin from camptothecin bark, the specific experimental steps are as follows:

[0023] 1. Rinse the surface dust of camphor tree bark with sterile water first, then soak it with ethanol with a volume ratio of 75% for 30s, wash off the surface ethanol with sterile water, and then soak it with mercuric chloride with a mass fraction of 0.1% for 30s. Rinse with sterile water for 3 to 5 times, and then cut it into small pieces of 5mm×5mm with a sterile knife;

[0024] 2. Inoculate the above materials on a PDA medium plate and incubate at a constant temperature of 28-30°C; when colonies grow obviously around the sample, pick colonies of different shapes and transfer them to the slope of the PDA medium, purify and cultivate at 28-30°C, and store spare;

[0025] 3. Strain activation: Inoculate the isolated endophytic fungi in the activation medium: glucose 20g / L, peptone 10g / L, magnesium sulfate 5g / L, potassium dihydrogen phosp...

Embodiment 2

[0029] Screen the new bacterial species producing camptothecin from the fruit of camptothecin, and the specific experimental steps are as follows:

[0030] 1. Rinse the surface dust of the camphor tree fruit with sterile water, then soak it in 75% ethanol by volume for 30s, wash off the surface ethanol with sterile water, then soak it in mercuric chloride with a mass fraction of 0.1% for 30s, sterile Rinse with water for 3 to 5 times, and then cut it into small pieces of 5mm×5mm with a sterile knife;

[0031] 2. Inoculate the above materials on a PDA medium plate and incubate at a constant temperature of 28-30°C; when colonies grow obviously around the sample, pick colonies of different shapes and transfer them to the slope of the PDA medium, purify and cultivate at 28-30°C, and store spare;

[0032] 3. Strain activation: Inoculate the isolated endophytic fungi in the activation medium: glucose 20g / L, peptone 10g / L, magnesium sulfate 5g / L, potassium dihydrogen phosphate 5g / L,...

Embodiment 3

[0036] Screen the new bacterial species producing camptothecin from camptothecin bark, the specific experimental steps are as follows:

[0037] 1. Rinse the surface dust of camphor tree bark with sterile water first, then soak it with ethanol with a volume ratio of 75% for 30s, wash off the surface ethanol with sterile water, and then soak it with mercuric chloride with a mass fraction of 0.1% for 30s. Rinse with sterile water for 3 to 5 times, and then cut it into small pieces of 5mm×5mm with a sterile knife;

[0038] 2. Inoculate the above materials on a PDA medium plate and incubate at a constant temperature of 28-30°C; when colonies grow obviously around the sample, pick colonies of different shapes and transfer them to the slope of the PDA medium, purify and cultivate at 28-30°C, and store spare;

[0039] 3. Strain activation: Inoculate the isolated endophytic fungi in the activation medium: glucose 20g / L, peptone 10g / L, magnesium sulfate 5g / L, potassium dihydrogen phosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com