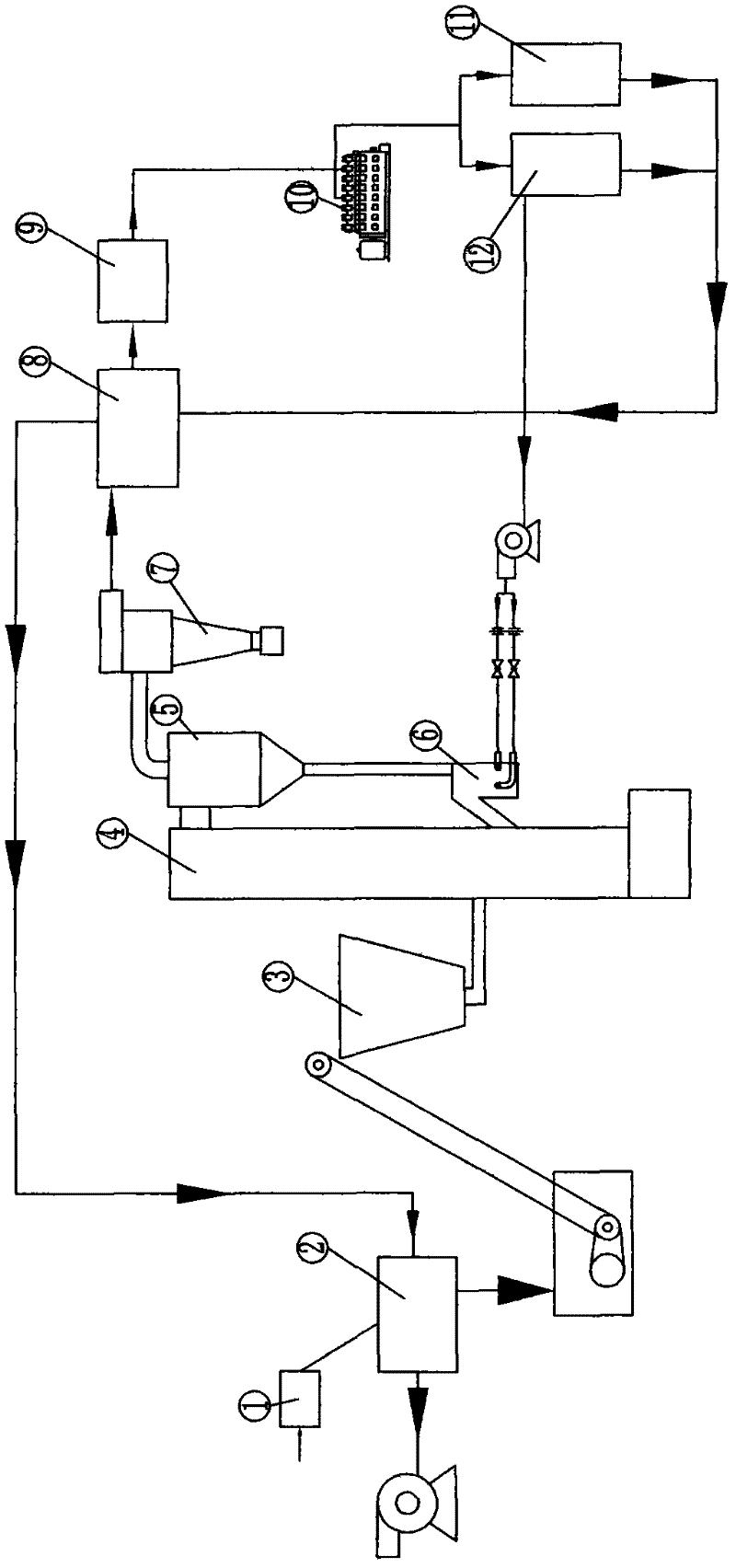

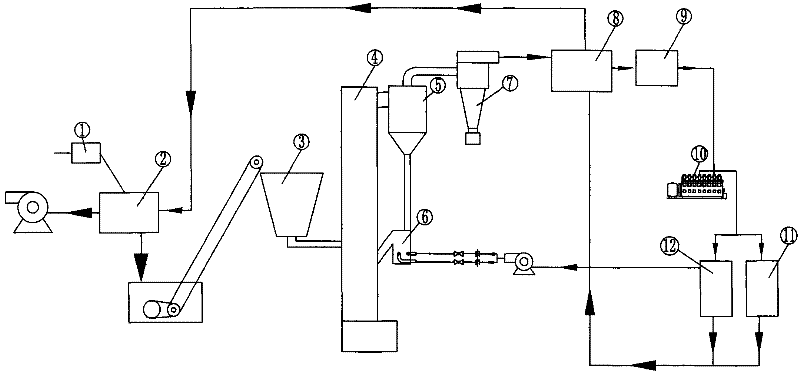

Biomass gasification generation system

A power generation system and biomass technology, applied in the direction of fuel oil system, gaseous engine fuel, granular/powdered fuel gasification, etc., can solve the problems of incomplete preheat recovery, low gasification efficiency, high energy consumption, etc., and achieve improved Raw material adaptability and the effect of improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The biomass raw material adopts wood chips with a water content of about 40%. After crushing and drying, the particle size is 6cm and the water content is 15%. It is added to the gasifier 4, and the air at 350°C preheated by the air preheater 12 is fed from the gasifier 4. The gasification furnace 4 is added at the bottom, and the high-temperature air and biomass undergo an efficient gasification reaction to generate high-temperature gas. The product undergoes gas-solid separation, and the unreacted residual carbon is collected and returned to the gasification furnace 4 through the feeding device for further reaction. The separated high-temperature gas enters the cyclone dust collector 7 for dust removal, and the gas cooled by the gas-flue gas heat exchanger 8 reaches 400°C. Using flue gas for energy recovery can prevent explosions when the gas-flue gas heat exchanger 8 leaks After being decoked, dedusted and further cooled by the purification device 9, the gas is sent t...

Embodiment 2

[0026] Biomass raw material adopts corn stalks with a water content of about 45%. After crushing and drying, the particle size is 4cm and the water content is 20%. It is added to the gasifier 4, and the air at 300°C is preheated by the air preheater for 12. 4 Add gasification furnace 4 at the bottom, high-temperature air and biomass undergo efficient gasification reaction to generate high-temperature gas, the product undergoes gas-solid separation, unreacted residual carbon is collected, and returns to gasification furnace 4 through the feeding device for further reaction . The separated high-temperature gas enters the cyclone dust collector 7 for dust removal, passes through the gas-flue gas heat exchanger 8, and the cooled gas reaches 400°C. Using flue gas for energy recovery can prevent gas-flue gas heat exchanger 8 from leaking Explosion, the gas is sent to the internal combustion generator set 10 to generate electricity after being decoked, dust removed and further cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com