EPS(Expanded Poly Styrol) wastewater treatment system

A wastewater treatment system and water inlet technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of high operating costs and large investment in membrane bioreactors and other problems, to achieve the effect of saving power, low investment cost and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

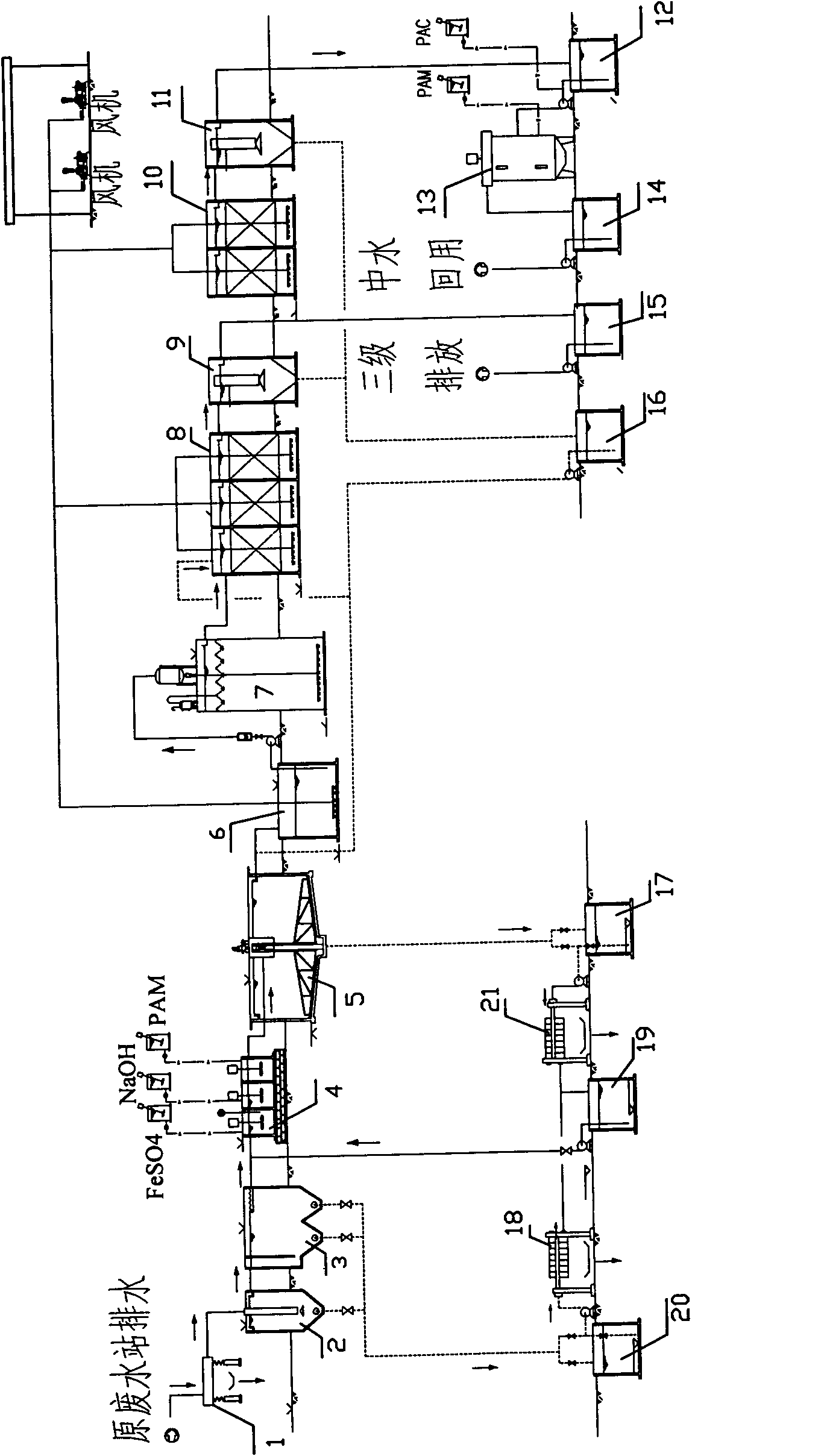

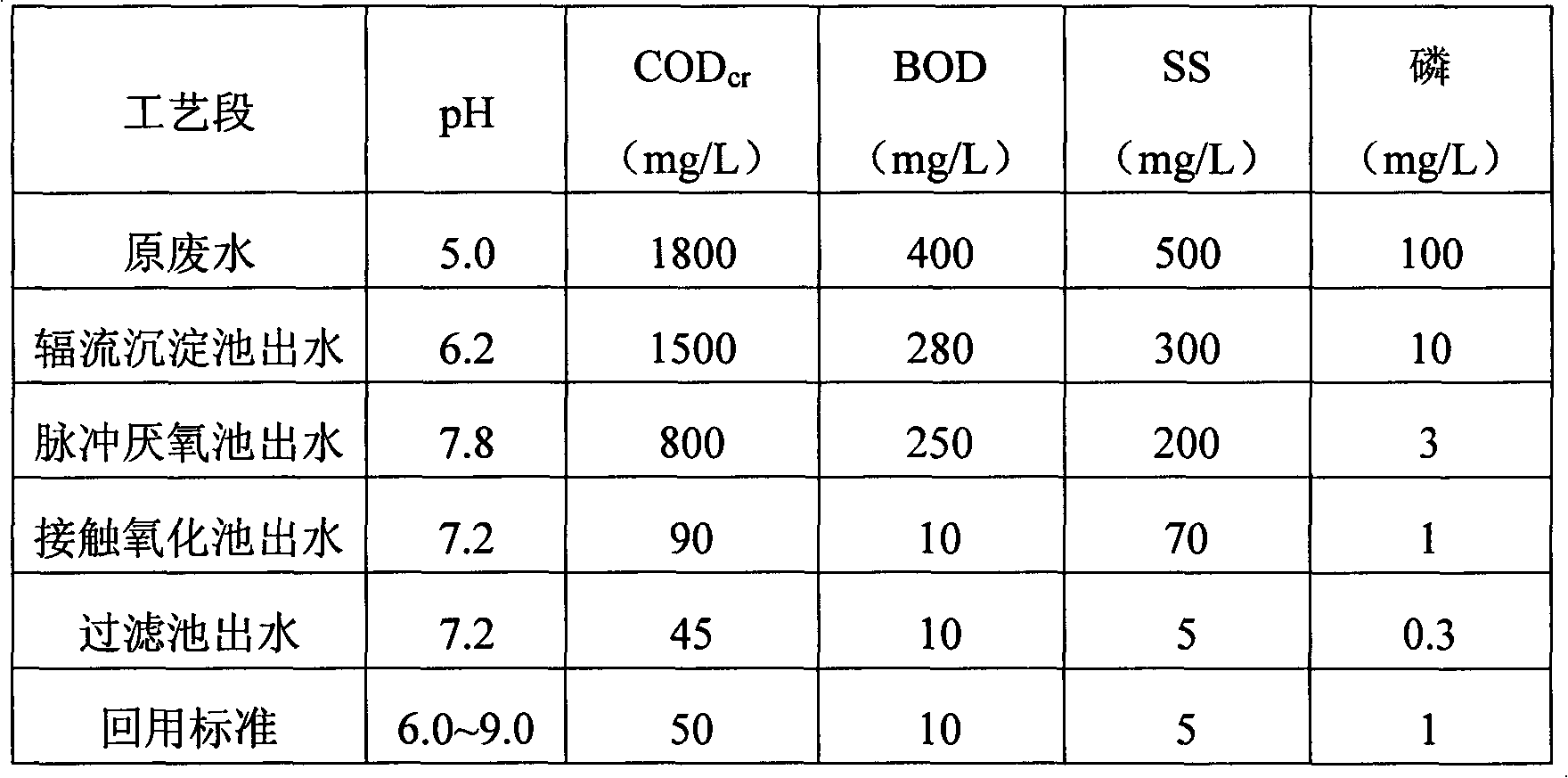

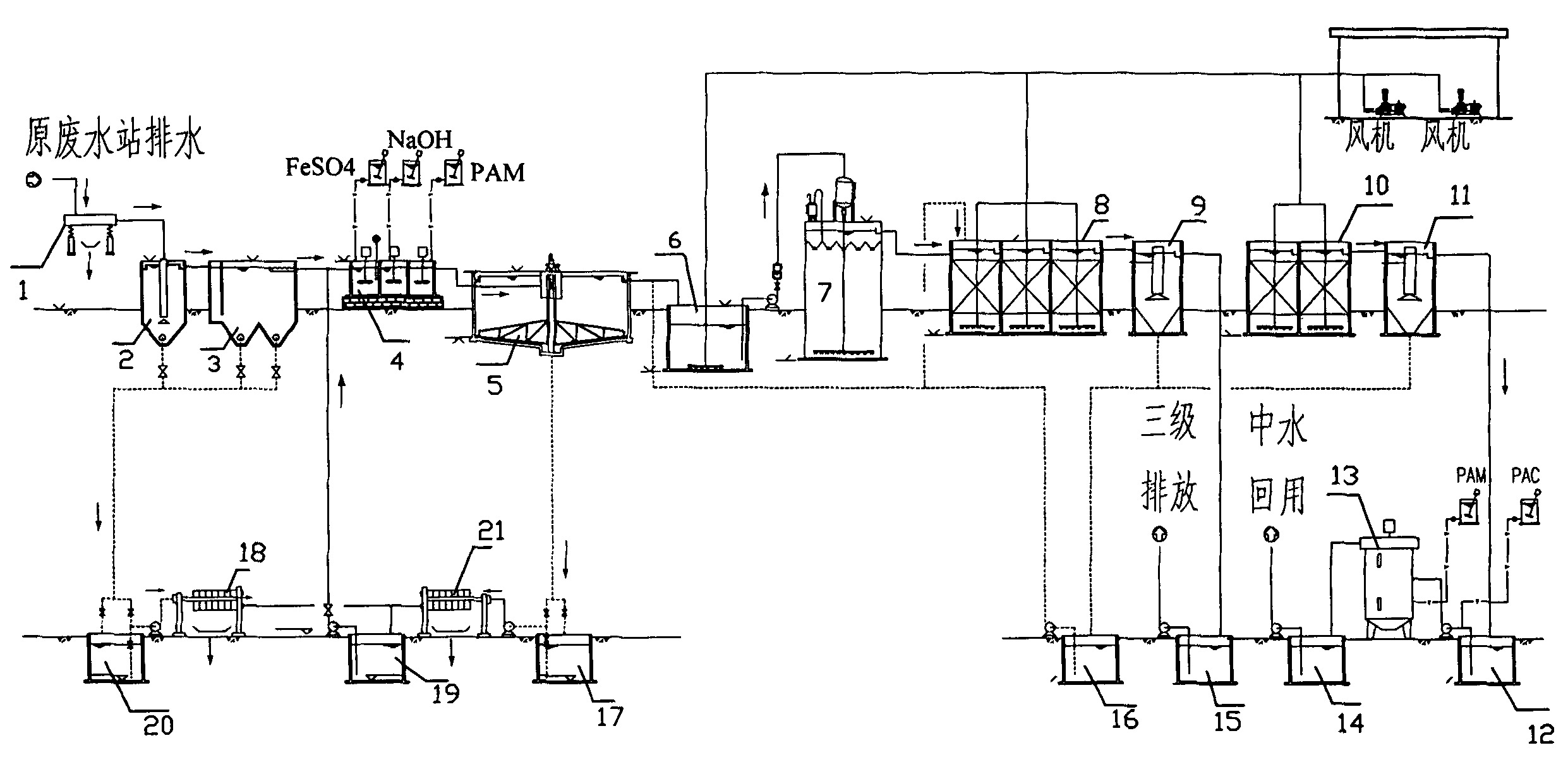

[0018] An EPS wastewater treatment system, the system includes a primary sedimentation tank group, a regulating tank 6, a pulse anaerobic reactor 7, a contact oxidation tank, a middle sedimentation tank 9, an intermediate tank 12, a coagulation sedimentation tower 13, and a reclaimed water reuse tank 14. Discharge pool 15. The primary settling tank group is sequentially composed of a vibrating screen 1, a vertical flow settling tank 2, an advective flow settling tank 3, a mixed flow reaction tank 4 and a radial flow settling tank 5 connected in series through pipelines.

[0019] The water inlet of the vibrating screen 1 is connected to the EPS production wastewater drainage pipe, the outlet of the vibrating screen 1 is connected to the water inlet of the vertical flow sedimentation tank 2, the water outlet of the vertical flow sedimentation tank 2 is connected to the water inlet of the advection sedimentation tank 3, and the outlet of the advection sedimentation tank 3 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com