On-line cleaning device and method for ball valve overhauling seal

A technology for checking and repairing sealing and cleaning devices, which is applied to cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc. It can solve problems such as inability to enter the volute, shortened service life of ball valve maintenance seals, and loose closure, etc., to achieve The effect of improving economic operation capacity, improving safety and stability, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

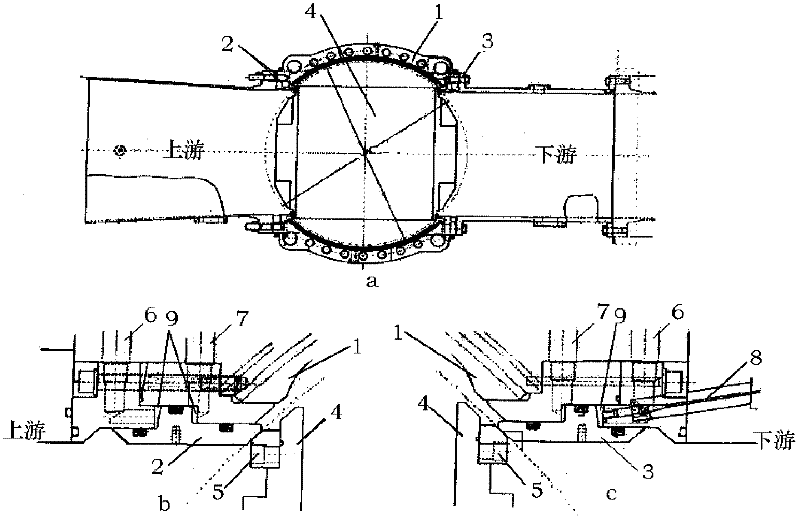

[0019] The invention provides an online cleaning device and method for checking and repairing the seal of a ball valve. The following will be described in conjunction with the accompanying drawings and embodiments.

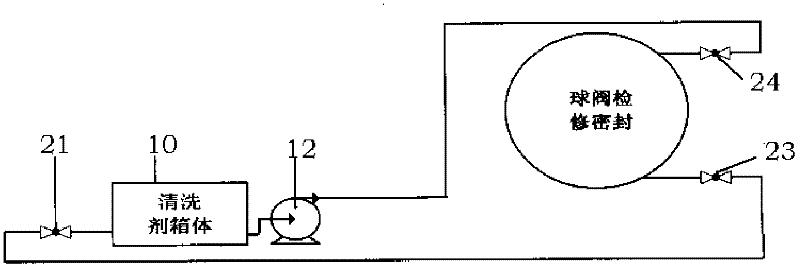

[0020] like figure 2 Shown is a schematic diagram of an online cleaning device for ball valve inspection and seal. A mobile cleaning device is adopted. The cleaning device is made of 304 stainless steel as a whole. The middle part of the box body 10 is equipped with a pull-out movable filter screen 11. The upper cover of the box body is a movable flip cover, which is convenient for on-site use and maintenance of the equipment in the box. The upper cover and the box body The joint is sealed with rubber to prevent the cleaning fluid 22 from overflowing; the electrical control box 15 is placed in front of the box body 10, the water pump 12 is placed at the lower part of the front end of the box body 10, and the base of the water pump is equipped with a shock absorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com