Catalyst for preparing synthesis gases through dry methane reforming (DMR) and preparation method thereof

A carbon dioxide and catalyst technology, which is applied in the field of nickel-based catalyst and its preparation, achieves the effects of high conversion rate, reduced cost, good anti-coking performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

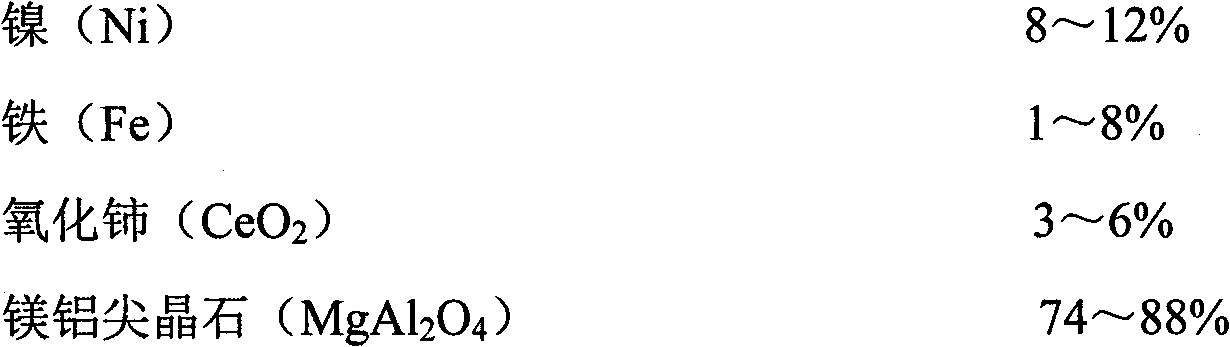

[0032]The components and mass percentages of the catalyst for producing synthesis gas by reforming methane and carbon dioxide are:

[0033]

[0034] The concrete steps of the preparation method of the catalyst of a kind of methane carbon dioxide reforming synthesis gas are as follows:

[0035] (1) Preparation of mesoporous MgAl 2 o 4 spinel carrier

[0036] First according to the ratio of the molar weight (mol) of magnesium nitrate: the molar weight (mol) of aluminum nitrate: the volume (ml) of distilled water is the ratio of 1: 2: 1300, magnesium nitrate and aluminum nitrate are added into distilled water, stir until Dissolved to prepare A mixed liquid. Then by the molar weight (mol) of cetyltrimethylammonium bromide: the volume (ml) of citric acid: the ratio of the volume (ml) of ethylene glycol is the ratio of 1: 2300: 300, under stirring condition First, mix cetyltrimethylammonium bromide and citric acid evenly, then add ethylene glycol and mix evenly to make B mixe...

Embodiment 2

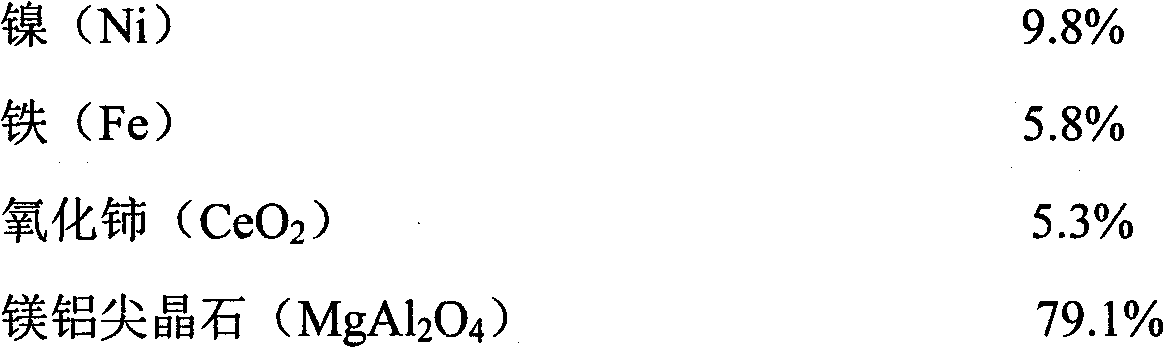

[0042] The components and mass percentages of the catalyst for producing synthesis gas by reforming methane and carbon dioxide are:

[0043]

[0044] A preparation method of a catalyst for methane carbon dioxide reforming synthesis gas, same as embodiment 1, wherein:

[0045] In the (1) step, mixed solution A is made up of the ratio of 1: 1.7: 1000 by the molar weight (mol) of magnesium nitrate: the molar weight (mol) of aluminum nitrate: the volume (ml) of distilled water. The mixed liquid B is made up with the ratio of molar weight (mol) of cetyltrimethylammonium bromide: volume (ml) of citric acid: volume (ml) of ethylene glycol is 1: 2000: 200. The temperature in the constant temperature water bath was 80°C. The temperature in the drying oven was 130° C., and the drying time was 45 hours. The calcination temperature in the muffle furnace was 680° C., and the calcination time was 5.5 hours.

[0046] In the (2) step, mixed solution C is made up of the ratio of 1: 0.2: ...

Embodiment 3

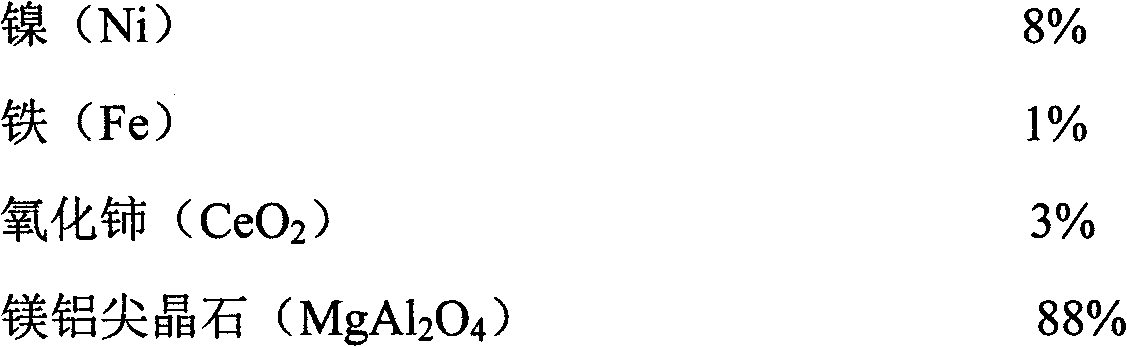

[0049] The components and mass percentages of the catalyst for producing synthesis gas by reforming methane and carbon dioxide are:

[0050]

[0051] A preparation method of a catalyst for methane carbon dioxide reforming synthesis gas, same as embodiment 1, wherein:

[0052] In the 1st (1) step, mixed solution A is made up of the ratio of 1: 2.3: 1500 by the molar weight (mol) of magnesium nitrate: the molar weight (mol) of aluminum nitrate: the ratio of the volume (ml) of distilled water. The mixed liquid B is made up in the ratio of 1:2500:400 molar weight (mol) of cetyltrimethylammonium bromide: volume (ml) of citric acid: volume (ml) of ethylene glycol. The temperature in the constant temperature water bath was 70°C. The temperature in the drying oven was 110° C., and the drying time was 55 hours. The calcination temperature in the muffle furnace was 720° C., and the calcination time was 5 hours.

[0053] In the (2) step, the mixed solution C is made up of nickel ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com