A method for printing and dyeing fabrics with vat dyes

A technology of dyes and fabrics, applied in the field of vat dyes printing and dyeing fabrics, which can solve the problems of unfavorable large-scale use, etc., and achieve the effects of good level dyeing and washing resistance, large economic value, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Cotton was dyed with indigo dyes using the method disclosed in this invention.

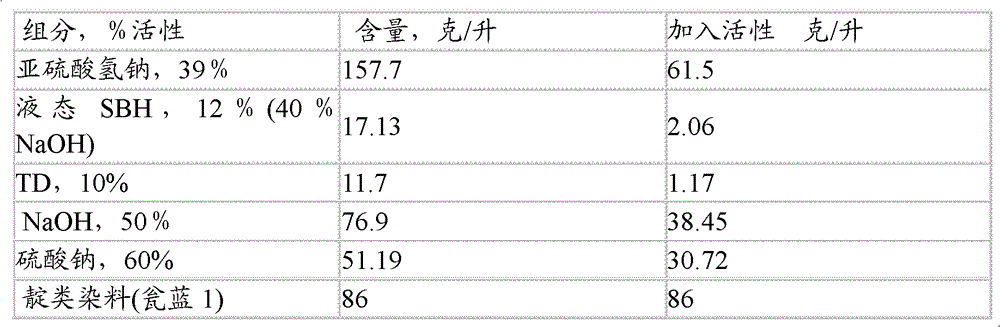

[0028] The masterbatch in the form of an aqueous mixture was prepared by mixing the following amounts in grams per liter of masterbatch (grams per liter):

[0029]

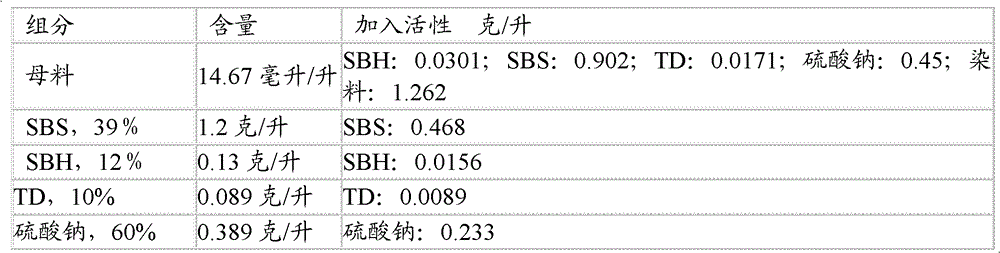

[0030] Using a pH meter, the pH value of the masterbatch was 13.34, and the oxidation-reduction potential (ORP) was -800 millivolts. The masterbatch was kept at room temperature for 2 hours without stirring, then a portion of it was mixed with additional bisulfite, borohydride, thiourea dioxide, sodium sulfate and diluted with water to prepare the following dye bath , expressing its content in units per liter of dyeing bath:

[0031]

[0032] The total amount of SBH added to form the dyebath (in g / L) (amount added to masterbatch + additional amount added to dyebath) was 0.0301+0.0156=0.0457 g / L. The total amount of SBS added to form the dyebath was 0.902+0.468=1.37 g / L. The total amount of TD added to form the dyebath ...

Embodiment 2

[0037] Example 2: Dyeing of cotton with indigo dyes using the method disclosed in this invention.

[0038] Cotton was dyed as described in Example 1, but with an initial pH of 9.65 in the dyebath. The dyebath color test results are relative to the L * a * b * The color on the color scale is L * : 16.26, a * : 1.72,b * : -12.71 measured on fabric dyed with indigo dye (using SBH, SBS under similar conditions). For dyed fabrics, ΔL * -0.56, Δa * =0.45, Δb * =0.61, ΔE=0.94. On a scale of 1-5, the wash resistance test after 5 washes received the highest rating of 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com