Method and device for preparing diamond film doped with ultrafine nano-structural metal particles

A diamond film and metal particle technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of low bonding strength of diamond film thickness film and substrate, which limits the promotion and control of the industrialization of diamond film preparation Complicated and other problems, to achieve the effect of improving the degree of bonding, prolonging the service life, and uniform thickness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

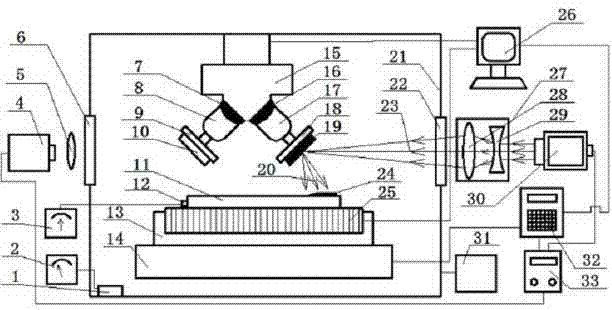

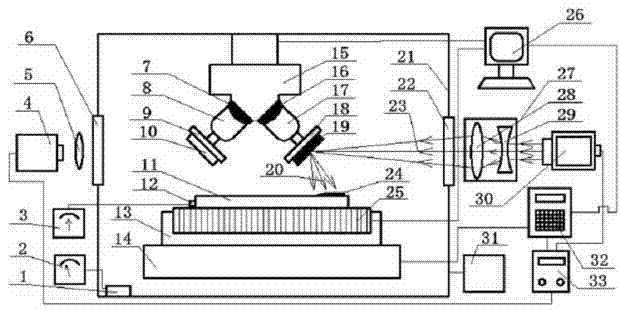

[0031] Use absolute ethanol and deionized water to clean the surface of the silicon-based alloy, clamp the cleaned silicon-based alloy on the heating device 25, and then fix the metal target 10 and the graphite target 19 on the metal target brackets 9 and 19 respectively. On the graphite target support 18, the rotating base A7 and the rotating base B16 are adjusted so that the included angles between the metal target 10 and the graphite target 19 and the surface of the silicon-based alloy in the horizontal direction are 135° and 45°, on the side of the silicon-based alloy. After attaching the temperature sensor 12, adjust the position of the table 14 so that the vertical distance from the upper surface of the silicon-based alloy to the lowermost end of the graphite target 19 is 2.5 mm. Use the vacuum pump 31 to pump the gas in the airtight working chamber 21, observe the pressure indicator 2, and make the internal pressure reach 3×10 -3 Pa, the computer 26 controls the heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com