Molecular sieve coating load manganese based composite oxide integrated catalyst and preparation method thereof

A technology of composite oxides and monolithic catalysts, applied in molecular sieve catalysts, physical/chemical process catalysts, separation methods, etc., can solve the problems of scarce precious metal resources, high prices, and high manufacturing costs, and achieve low manufacturing costs, high-temperature activity, and Not easy to fall off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 15.79g of 50% Mn(NO 3 ) 2 solution, 2.30g Cu(NO 3 ) 2 ·3H 2 O. 2.89g Silicalite-1 molecular sieve, add 6.86g water, stir to form a slurry, and then apply the slurry to a size of 50mm×25mm×40mm, with an opening rate of 195cell / in 2 , On the cordierite honeycomb ceramics with a mass of 30.2g, blow out the residual liquid in the honeycomb channel. At this time, there is still a part of the slurry remaining. Air the cordierite honeycomb ceramics at room temperature until the surface is dry, and then dry at 120°C for 1 hour, and then in the muffle Baking in a furnace at 500°C for 1 hour. Repeat the above impregnation, drying, and calcination twice, the last calcination temperature is 500°C, and calcination is performed for 4 hours to obtain the monolithic catalyst of the present invention.

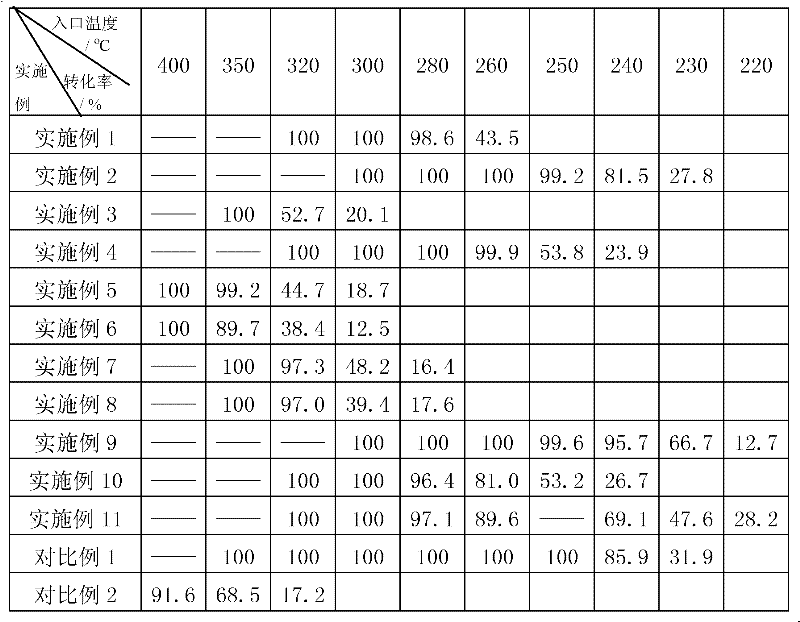

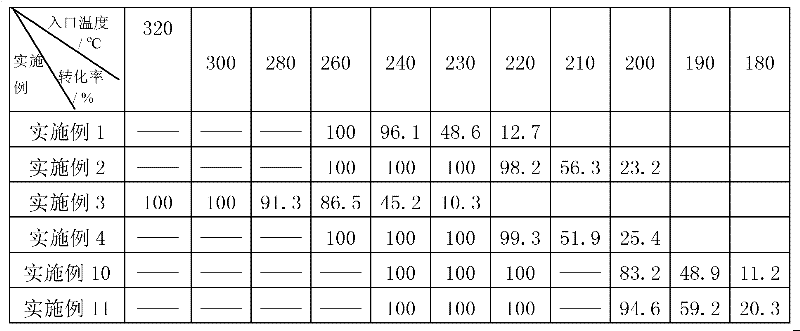

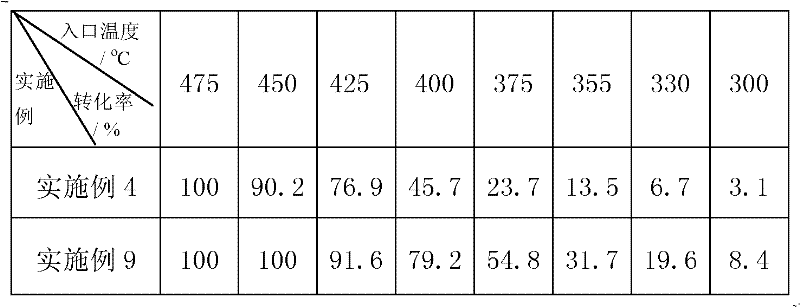

[0020] The prepared monolithic catalyst is made into a cylindrical shape, packed in a fixed-bed catalytic combustion reactor, and the catalytic combustion of toluene or ethyl ...

Embodiment 2

[0022] Weigh 15.82g of 50% Mn(NO 3 ) 2 solution, 2.29g Cu(NO 3 ) 2 ·3H 2 O, 2.91g H-ZSM-5, 11.16g citric acid, 1.18g polyethylene glycol, add 9.92g water, stir to form a slurry, and then apply the slurry to a size of 50mm×25mm×40mm, with a porosity of 195cell / in 2 , On the cordierite honeycomb ceramics with a mass of 30.2g, blow out the residual liquid in the honeycomb channel. At this time, there is still a part of the slurry remaining. Air the cordierite honeycomb ceramics at room temperature until the surface is dry, and then dry at 120°C for 1 hour, and then in the muffle Baking in a furnace at 500°C for 1 hour. Repeat the above impregnation, drying, and calcination twice, the last calcination temperature is 500°C, and calcination is performed for 4 hours to obtain the monolithic catalyst of the present invention.

[0023] The catalytic combustion effects of the prepared monolithic catalyst on toluene and ethyl acetate are shown in Table 1 and Table 2, respectively. ...

Embodiment 3

[0025] Weigh 15.76g of 50% Mn(NO 3 ) 2 solution, 2.26g Cu(NO 3 ) 2 ·3H 2 O, 2.93g TS-1, 11.62g citric acid, 1.19g polyethylene glycol, add 9.90g water, stir to form a slurry, and then apply the slurry to a size of 50mm×25mm×40mm, with an opening ratio of 195cell / in 2 , On the cordierite honeycomb ceramics with a mass of 30.5g, blow out the residual liquid in the honeycomb channel. At this time, there is still a part of the slurry remaining. Air the cordierite honeycomb ceramics at room temperature until the surface is dry, and then dry at 120°C for 1 hour, and then in the muffle Baking in a furnace at 500°C for 1 hour. Repeat the above impregnation, drying, and calcination twice, the last calcination temperature is 800°C, and calcination is performed for 4 hours to obtain the monolithic catalyst of the present invention.

[0026] The catalytic combustion effects of the prepared monolithic catalyst on toluene and ethyl acetate are shown in Table 1 and Table 2, respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| F | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com