Mobile phone shell and manufacturing method thereof

A mobile phone shell and sheet technology, applied in the direction of the structure of the phone, can solve the problems of easy shielding of mobile phone signals, affecting the appearance of products, etc., and achieve the effects of light weight, increased service life, and guaranteed consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a method for preparing a mobile phone shell, said method comprising the following steps:

[0029] A, preparation sheet, it further comprises the steps:

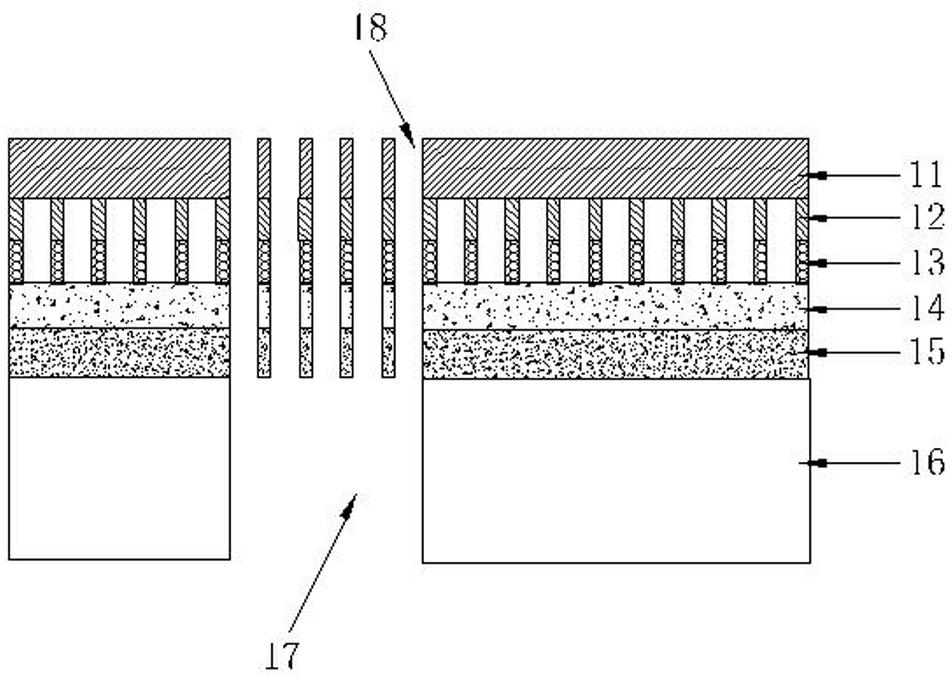

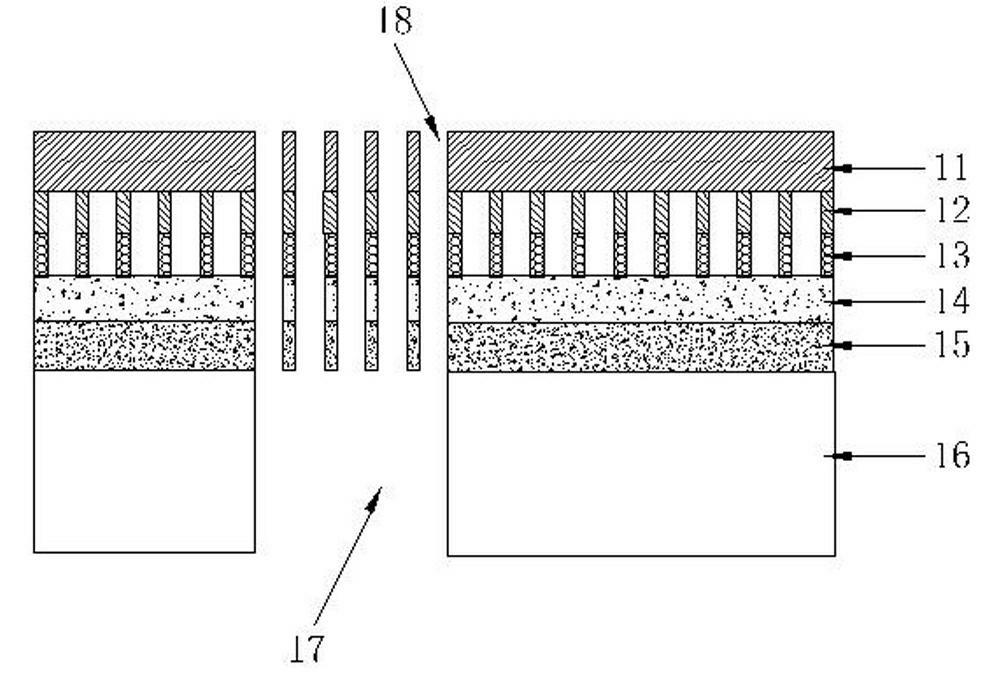

[0030] After forming a metal layer on one surface of the base sheet 11, print the ink layer: the base sheet 11 can be a variety of plastic sheets, which require transparency or translucence, and have good stretch formability and temperature shock resistance , has a certain surface hardness, smooth or matte surface, brushed surface can be, for example, it can be one or more of transparent polycarbonate (PC), polyethylene terephthalate (PET) .

[0031] The metal layer is a layer of metal layer formed on the base sheet 11 through physical vapor deposition, electroplating, printing, spraying, etc. methods such as physical vapor deposition, electroplating, printing, spraying, etc. are known by those skilled in the art. It is well known and will not be repeated here. The metal layer is ...

Embodiment 1

[0041] The transparent base layer sheet 11 provided by Bayer is selected, the material is polycarbonate (PC), the model is DMX 1H00MY-112, both sides are glossy, the thickness is 0.175mm, and the specification is 230×200mm.

[0042] The operating surface of the base sheet 11 is coated with an indium-tin alloy by sputtering to obtain a metal layer with a light transmittance of 2%.

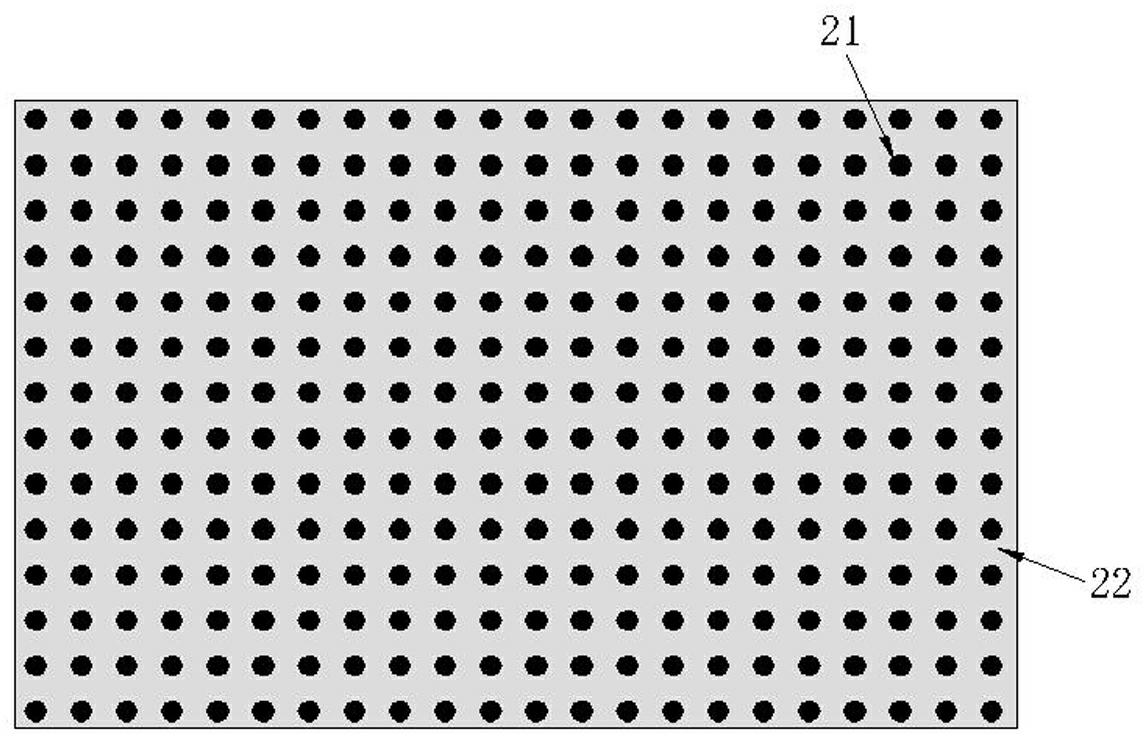

[0043] On the surface of the metal layer, an ink layer with a mesh pattern and positioning holes are printed. The ink used is XWR black ink provided by Powerlong, Germany. The screen used for printing is 300 mesh, and the printing thickness of the ink layer is 0.005mm. The circular holes in the mesh pattern are arranged regularly, the diameter of the circular holes is 0.3mm, and the hole spacing in the horizontal and vertical directions is both 0.6mm.

[0044] Put the above base sheet printed with metal layer and ink layer into the solution of model Rts-700 provided by Xinhongda Company for deplatin...

Embodiment 2

[0053] The transparent base layer sheet 11 provided by Bayer is selected, the material is polycarbonate (PC), the model is DMX 1H00MY-112, both sides are glossy, the thickness is 0.175mm, and the specification is 230×200mm.

[0054] The operating surface of the base sheet 11 is coated with an indium-tin alloy by sputtering to obtain a metal layer with a light transmittance of 4%.

[0055] On the surface of the metal layer, an ink layer with a mesh pattern and positioning holes are printed. The ink used is XWR black ink provided by Powerlong, Germany. The screen used for printing is 300 mesh, and the printing thickness of the ink layer is 0.01mm. The circular holes in the mesh pattern are arranged regularly, the diameter of the circular holes is 0.5 mm, and the hole spacing in the horizontal and vertical directions is 1 mm.

[0056] Put the above base sheet printed with metal layer and ink layer into the solution of model Rts-700 provided by Xinhongda Company for deplating, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com