Remote control electric rolling door alternating-current motor control circuit with automatic locking function

A technology of automatic locking and AC motor, which is applied in the field of rolling shutter door control, can solve problems such as unguaranteed safety, and achieve the effect of improving anti-theft performance and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

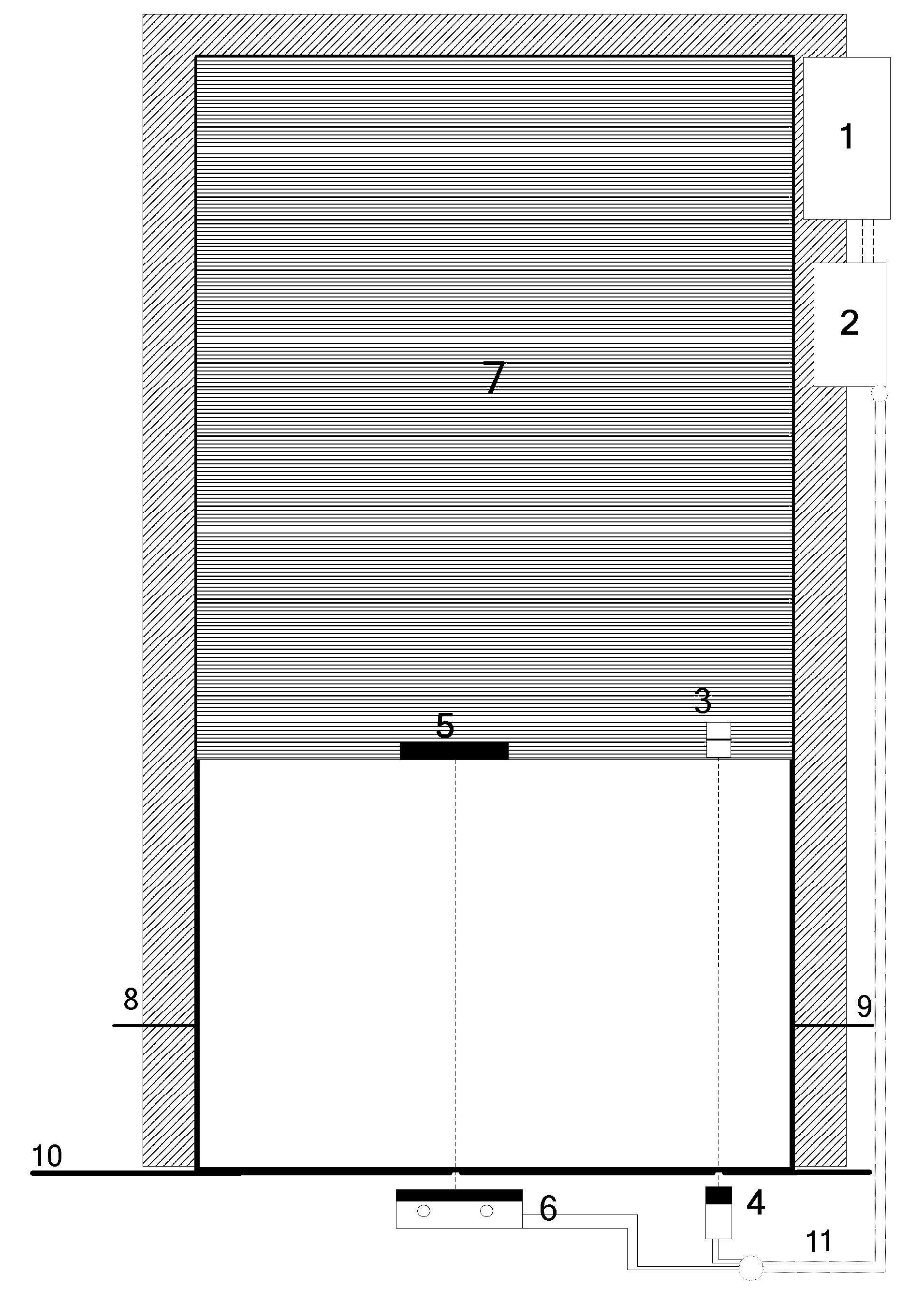

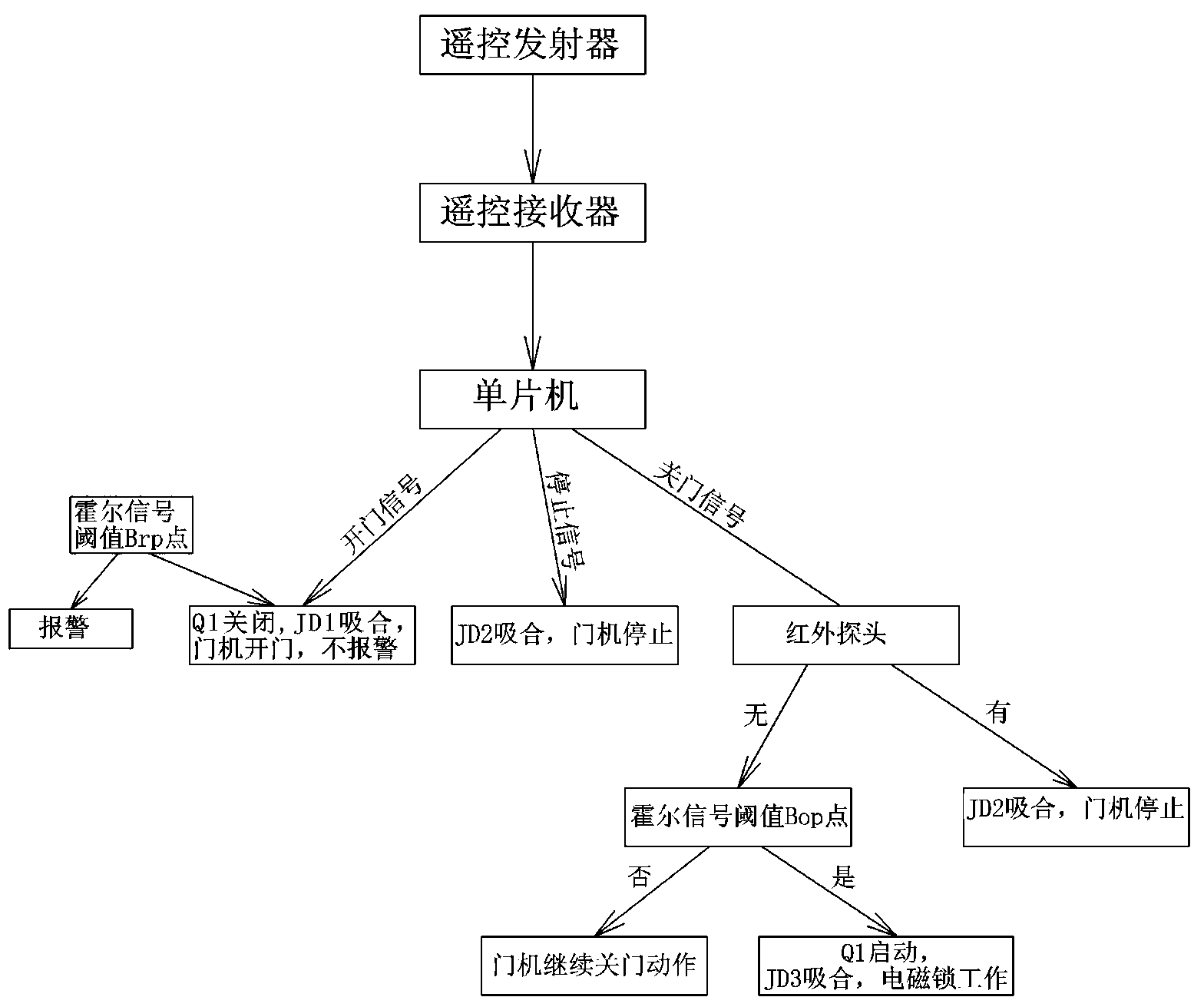

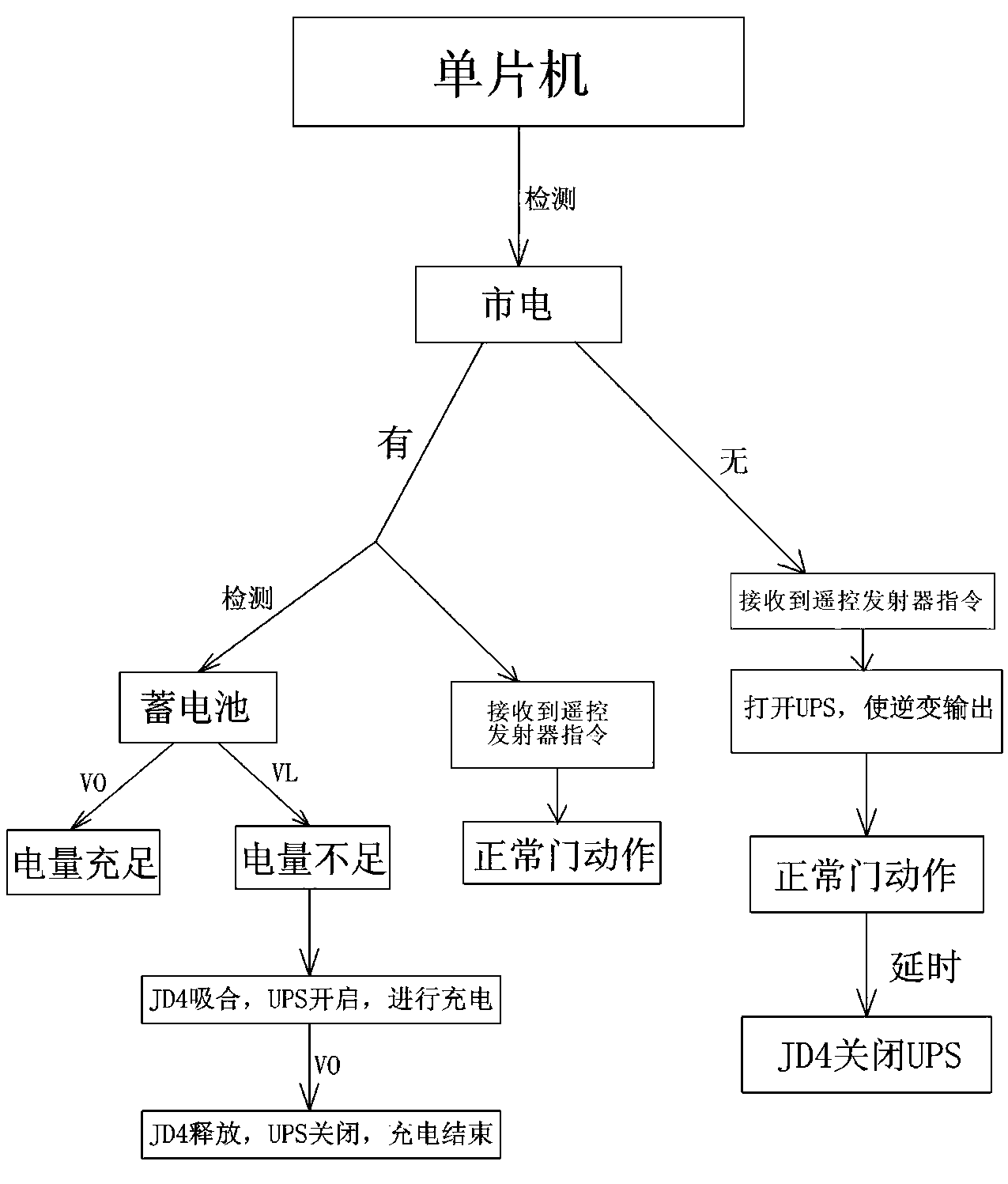

[0023] Embodiment one: see figure 1 and Figure 5 , the electromagnetic lock is fixed on the ground, and the lower edge of the rolling shutter door is fixed with an iron plate 5. The rolling door machine is installed on one side of the reel and closed, and the control chip is installed near the motor or hidden in the box near the wall. The control line of the electric control lock is connected to the output terminal of the control chip U1 after being connected through the PNP Darlington tube Q1. At the same time, a lower limit probe is set on the ground. The lower limit probe in this embodiment adopts a Hall switch, and a magnet is set on the lower edge of the rolling shutter door, and the two form an induction system. The signal end of the Hall probe is connected to the cathode of the diode D3, the anode of the diode D3 is connected to the signal input end of the control chip U1 through the resistor R8, and the anode of the diode D3 is connected to the high level through th...

Embodiment 2

[0039] Embodiment two: see figure 1 and Figure 5 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that an infrared sensing module is provided, that is, infrared directing or reflective sensors are installed on both sides of the door frame close to the ground, and the infrared sensors on both sides are respectively installed. The signal line of the through-shooting or reflection sensor is connected with the input end of the control chip. If there is an obstacle under the door during the process of closing the door, the signal from the transmitter of the infrared probe CON4 will be blocked, and the receiving end of the infrared probe will send out a level signal. After the 4th pin of the microcontroller detects the output signal of the infrared probe , will send a high-level signal to pin 14, drive the relay JD2 to pull in, and the door movement will stop.

Embodiment 3

[0040] Embodiment three: see figure 2 and Figure 5 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the automatic locking module includes an electric control lock and an electromagnetic induction unit. Lock 19, have the slot 18 that cooperates with electric mortise lock on the corresponding position on the door plate simultaneously, and electromagnetic induction unit is that magnet 3 is installed on the lower edge of rolling shutter door, and limit probe 4 is set on the ground directly below magnet simultaneously, and this limit probe 4 The signal terminal of the electric control lock is connected with the input terminal of the control chip U1, and the control terminal of the electric control lock is connected with the PNP Darlington tube Q1 and then connected with the output terminal of the control chip U1. This embodiment uses an electric mortise lock. When the door is closed to the fast bottom,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com