Method for installing and using cable-stayed bridge reinforced concrete cable tower prestressed system

A reinforced concrete and prestressed technology, applied in cable-stayed bridges, bridges, bridge parts, etc., can solve problems such as large-area sealing of anchors, and achieve the effect of less concrete volume, less impact, and avoidance of steel bar truncation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

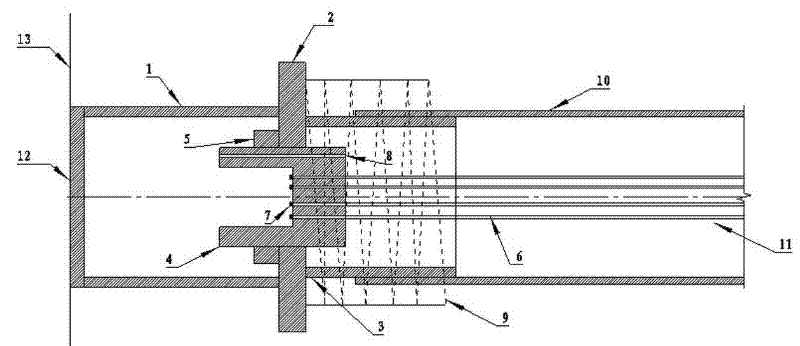

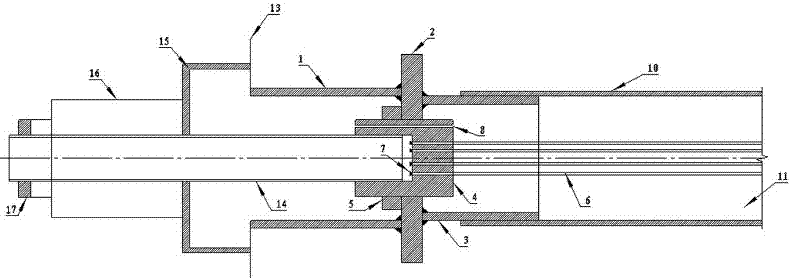

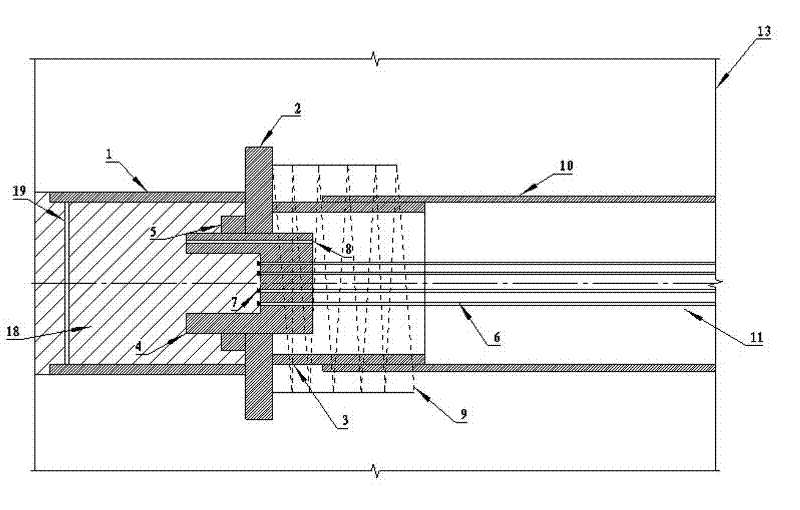

[0032] (1) Prefabrication of prestressed system

[0033] A prestressed system combining prestressed steel wire bundles, pier head anchors and anchor boxes is adopted. The anchor rings and nuts of the pier head anchors must be prefabricated in advance, and the prestressed steel wire bundles, pier head anchors and the anchors worn on the prestressed steel wire bundles shall be prefabricated. The corrugated pipe is installed as a whole, in which the anchor ring and the nut are threaded, and the prestressed steel wire bundle is fixed on the anchor cup with clips. The anchor box is composed of four parts: the inner sleeve, the outer sleeve, the anchor backing plate with a hole in the middle and the protective cover. Installed at the end of the outer sleeve after the prestressing installation is completed, it is used to protect the anchor box from debris. The inner diameter of the inner and outer sleeves and the hole diameter of the anchor plate must meet the requirements of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com