Method for producing biological water-purifying agent through microbe mutual fermentation of chicken manure

A technology for fermenting chicken manure and water purifying agent is applied in the field of agricultural waste utilization, which can solve the problems of livestock and poultry manure pollution and increase urban pressure, and achieve the effects of improving water quality, high efficiency and high conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The effective microbial strains in the fermentation process of chicken manure were Aspergillus oryzae [ACCC30155], Saccharomyces cerevisiae [ACC20065], Bacillus subtilis [ACCC10148] and photosynthetic bacteria [ACCC10650], all purchased from China Agricultural Microbiology Center.

[0015] Aspergillus oryzae and yeast medium: 10% wort medium, no agar is added as a liquid medium, and 2% agar is added as a solid medium.

[0016] Bacillus subtilis culture medium: nutrient broth, liquid medium without agar, solid medium with 2% agar.

[0017] Photosynthetic bacteria medium: PSB medium, CH 3 COONa 3.0g·L -1 , (NH 4 ) 2 SO 4 , 1.5g·L -1 , MgSO 4 ·7H 2 O0.8g L -1 , KH 2 PO 4 0.3g·L -1 , K 2 HPO 4 0.5g·L -1 , yeast extract powder 1.2g·L -1 , pH7.5, no agar is used as a liquid medium, and 2% agar is added as a solid medium.

[0018] Inoculate the above-mentioned strains on the corresponding slopes for activation, and then inoculate them into the corresponding Erl...

Embodiment 2

[0026] The activation culture of the strain is the same as in Example 1.

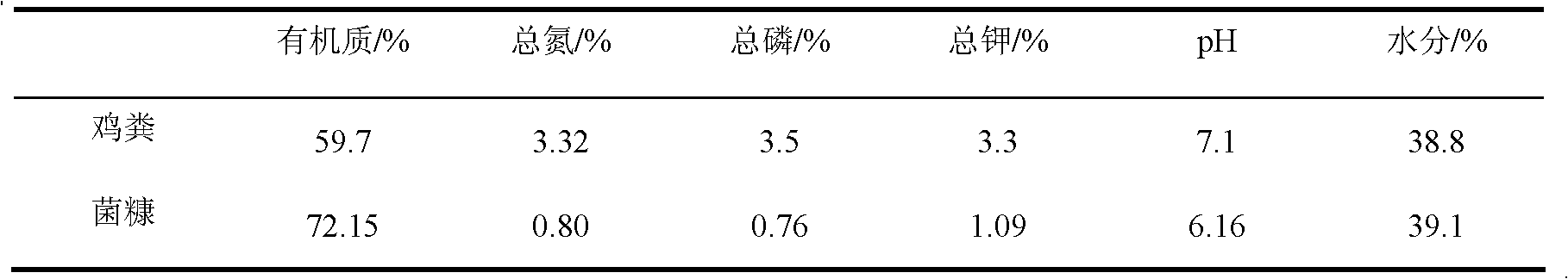

[0027] 55wt% fresh chicken manure, 27% Pleurotus eryngii fungus chaff, 18% inorganic compound fertilizer solid raw material are mixed uniformly, then inoculated with Aspergillus oryzae 6wt% accounting for solid raw material gross weight, saccharomyces cerevisiae 2wt%, Bacillus subtilis 2wt% and 2 wt% of photosynthetic bacteria, then the thickness of the material is kept at 50-60 cm, stacked and fermented at normal temperature for 15 days, and stirred twice during the fermentation process to obtain the product of the present invention. The number of effective microorganisms after fermentation is about 4×10 8 CFU / g, according to different users, inorganic fertilizers can be added to make products with different nutrients.

[0028] Get 100 kilograms of above-mentioned products, add inorganic compound fertilizer (nutrient is 17%N on the market: the product of 5%P: 8%K all can) 20 kilograms are mixed, both ...

Embodiment 3

[0031] The activation culture of the strain is the same as in Example 1.

[0032] 55wt% fresh chicken manure, 27% Pleurotus eryngii fungus chaff, 18% inorganic compound fertilizer solid material are mixed uniformly, then inoculate 2wt% of Aspergillus oryzae accounting for the total weight of solid material, 1wt% of Saccharomyces cerevisiae, 1wt% of Bacillus subtilis and 1 wt% of photosynthetic bacteria, then the thickness of the material is kept at 50-60 cm, stacked and fermented at normal temperature for 15 days, and stirred twice during the fermentation process to obtain the product of the present invention. The effective number of microorganisms after fermentation is 3×10 8 CFU / g, according to different users, inorganic fertilizers can be added to make products with different nutrients.

[0033] Get 100 kilograms of above-mentioned products, add inorganic compound fertilizer (nutrient is 17%N on the market: the product of 5%P: 8%K all can) 15 kilograms mix, can obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com