Method for extracting 1-octacosanol from bagasse

A technology of octacosanol and bagasse is applied in chemical instruments and methods, preparation of organic compounds, production of bulk chemicals, etc., can solve the problems of long extraction time, complex process, large energy consumption, etc., and achieves reduction in extraction Effects of pressure and temperature, increasing extraction efficiency, and reducing extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

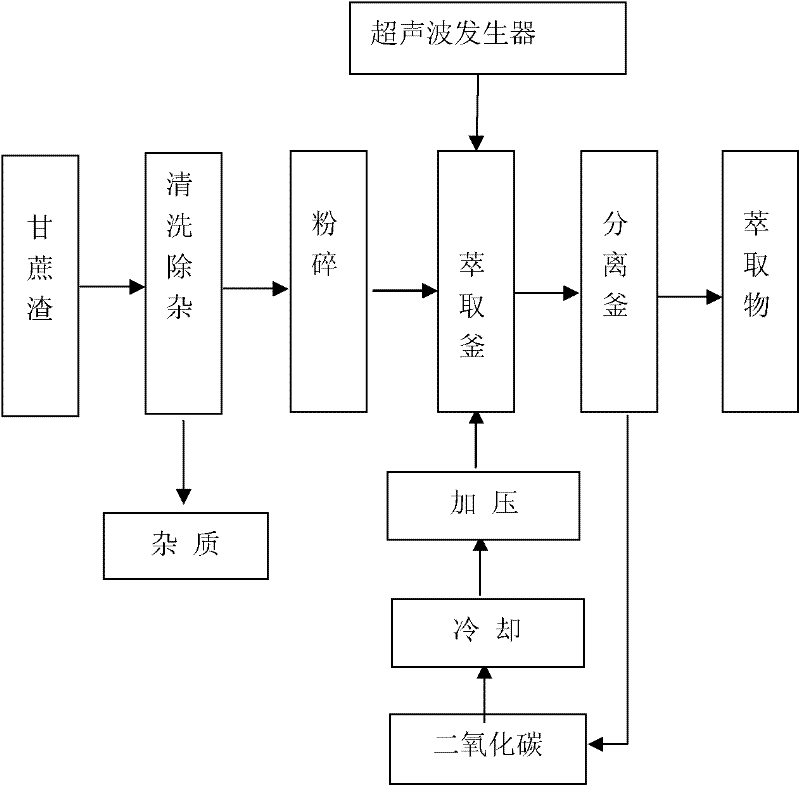

Method used

Image

Examples

Embodiment 1

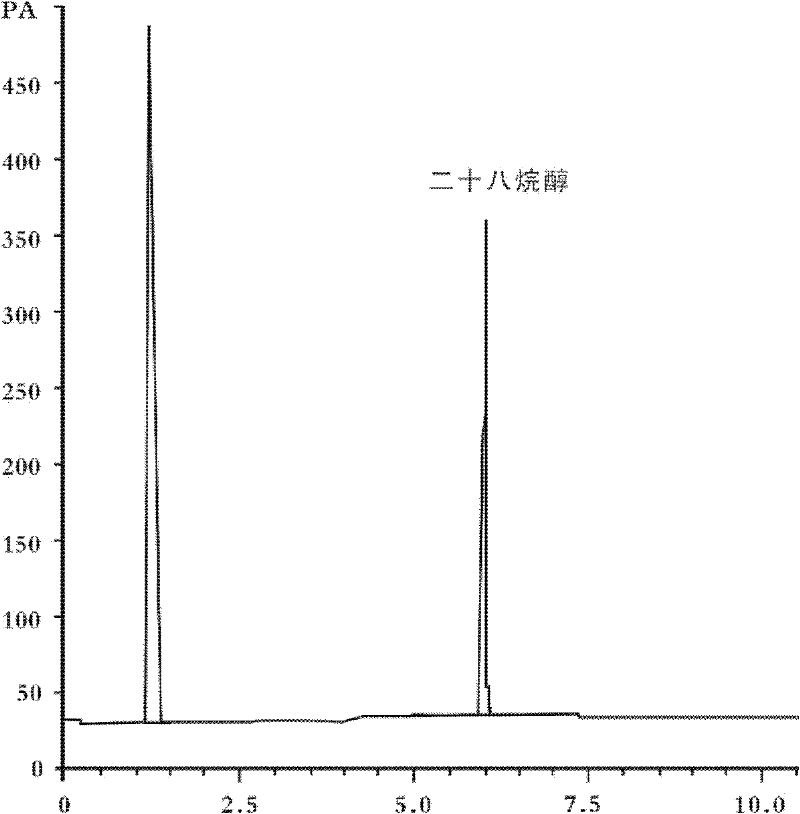

[0029] Bagasse is sorted, cleaned, sterilized, dried, pulverized into powder by a pulverizer, and passed through a 200-mesh sieve; 1 kg of bagasse powder with a crushed particle size of 200 mesh is put into an extraction kettle with a built-in plug-in ultrasonic device to form a filling layer; Driven by pressure, supercritical carbon dioxide enters the extraction kettle from the bottom, passes through the bagasse powder in the filling layer, then flows out of the extraction kettle from the top, and enters the separation kettle through a pressure reducing valve. After 2 hours of extraction, the separation kettle is opened after the pressure is reduced. Separate the product into an open plastic tank to obtain about 55 grams of ointment; the ultrasonic frequency during extraction is 16kHz, the power density is 80W / L, and the ultrasonic irradiation mode is intermittent time / continuous irradiation time is 4s / 4s; The temperature of the kettle is 35°C and the pressure is 15Mpa; the te...

Embodiment 2

[0031] Bagasse is sorted, cleaned, sterilized, dried, pulverized into powder by a pulverizer, and passed through a 60-mesh sieve; 1 kg of bagasse powder with a particle size of 60 mesh is put into an extraction kettle with a built-in plug-in ultrasonic device to form a filling layer; Driven by pressure, supercritical carbon dioxide enters the extraction kettle from the bottom, passes through the bagasse powder in the filling layer, flows out of the extraction kettle from the top, and enters the separation kettle through a pressure reducing valve. After 3 hours of extraction, the separation kettle is opened after depressurization. The product is separated into an open plastic tank to obtain about 51 grams of ointment; wherein the ultrasonic frequency is 24kHz, the power density is 120W / L, and the ultrasonic irradiation mode is intermittent time / continuous irradiation time is 8s / 8s; extraction The temperature of the kettle is 50°C and the pressure is 35Mpa; the temperature of the...

Embodiment 3

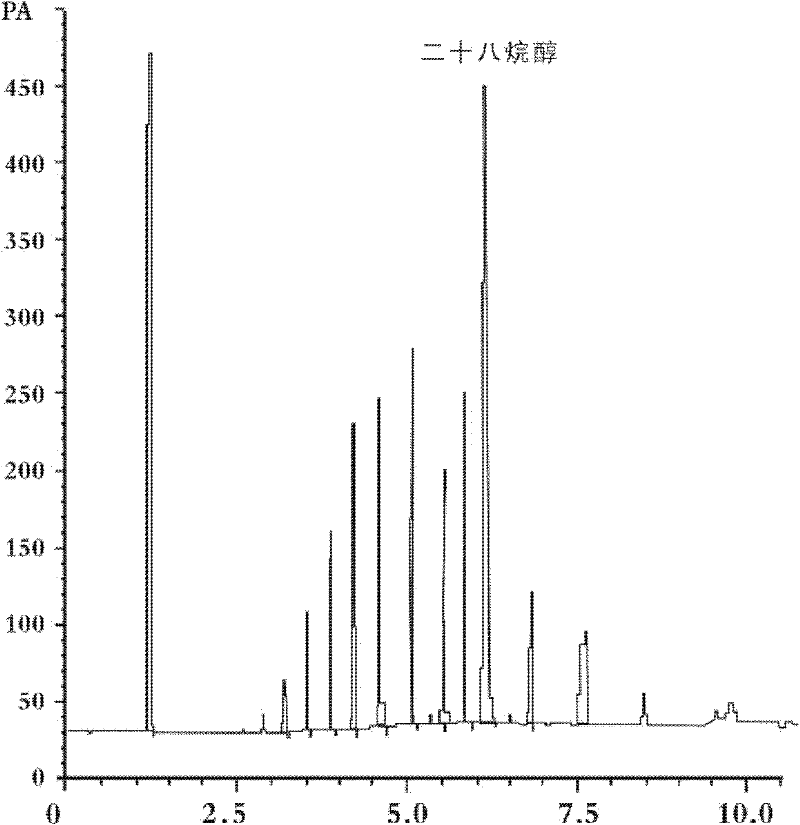

[0033] Bagasse is sorted, cleaned, sterilized, dried, pulverized into powder with a pulverizer, and passed through a 100-mesh sieve; 1 kg of bagasse powder with a particle size of 100 mesh is put into an extraction kettle with a built-in plug-in ultrasonic device to form a filling layer; Driven by pressure, supercritical carbon dioxide enters the extraction kettle from the bottom, passes through the bagasse powder in the filling layer, then flows out of the extraction kettle from the top, and enters the separation kettle through a pressure reducing valve. After 4 hours of extraction, the separation kettle is opened after the pressure is reduced. The product is separated into an open plastic tank to obtain about 62 grams of ointment; wherein the ultrasonic frequency is 20kHz, the power density is 100W / L, and the ultrasonic irradiation mode is intermittent time / continuous irradiation time is 6s / 6s; extraction The temperature of the kettle is 45°C and the pressure is 30Mpa; the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com