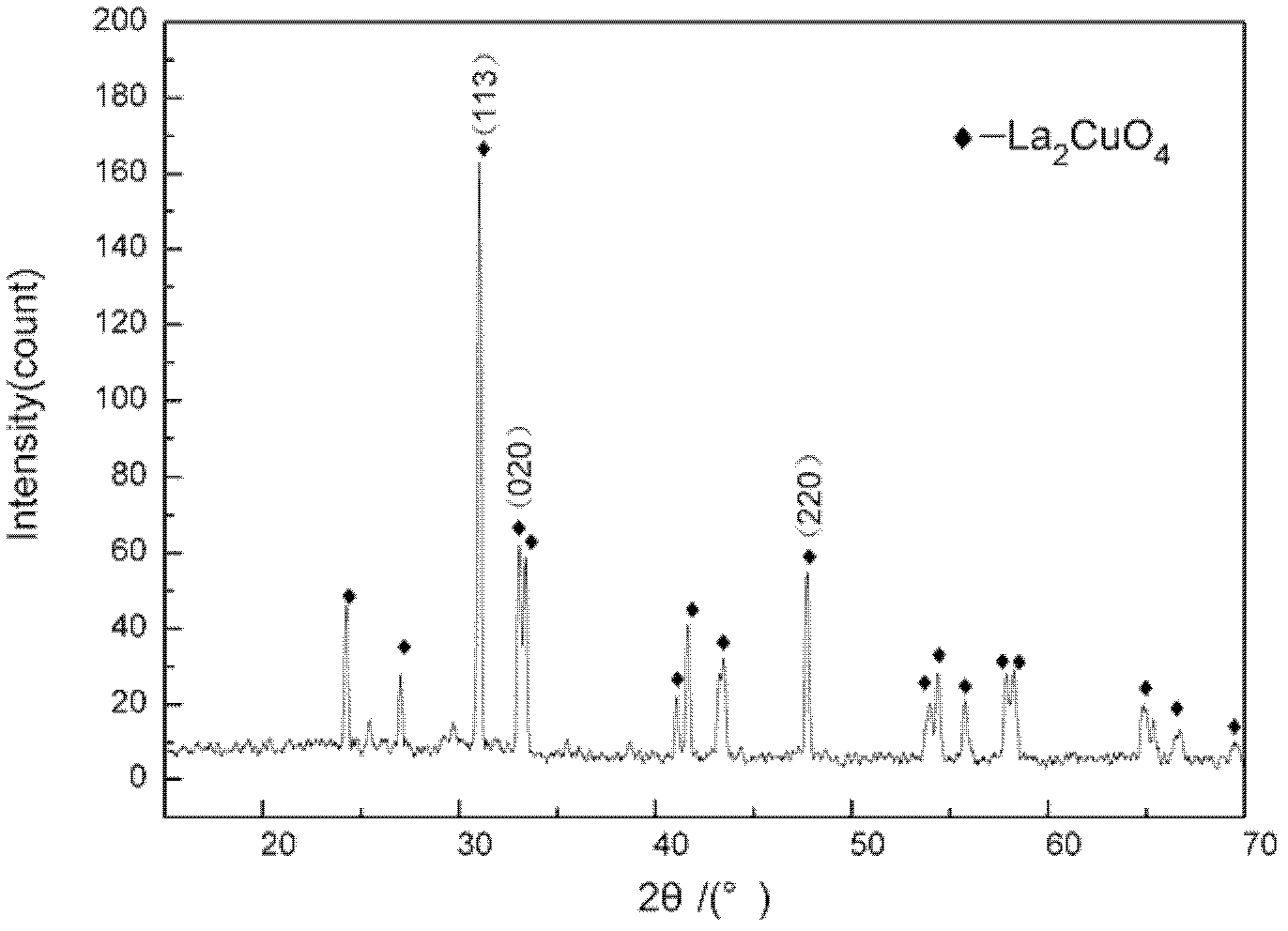

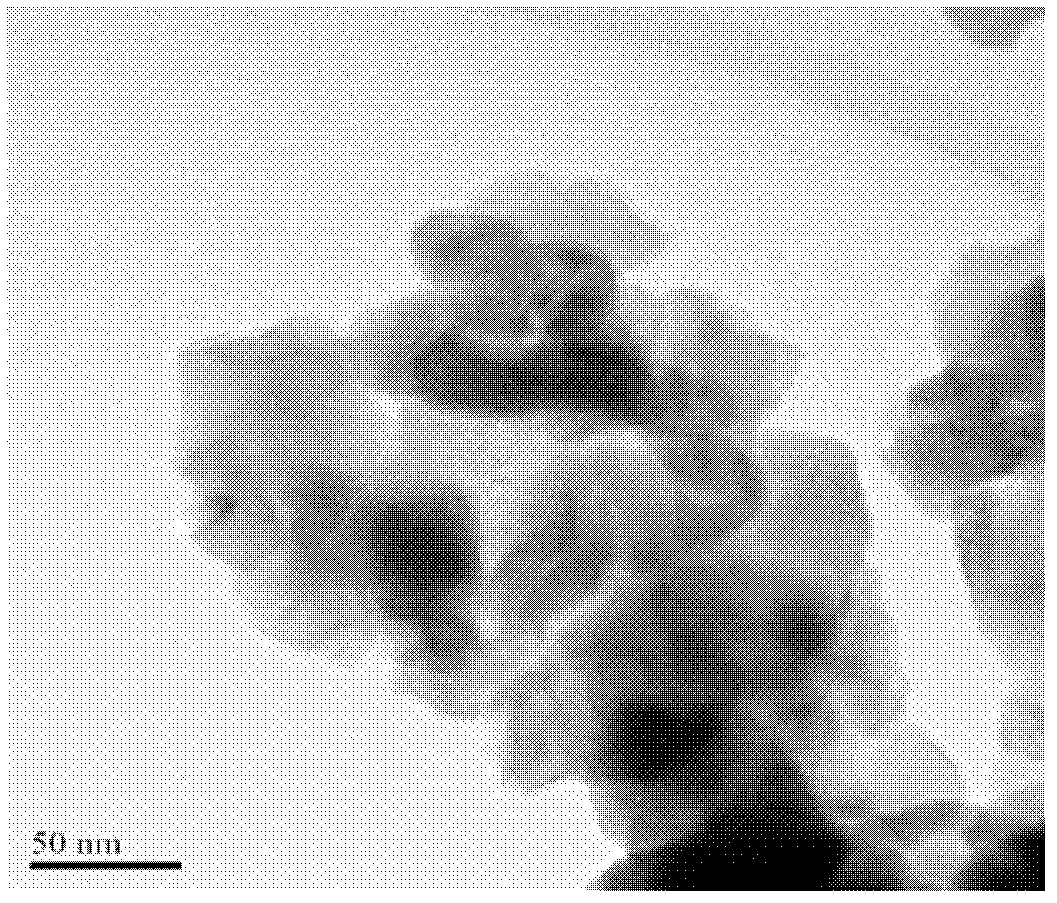

Method for preparing lanthanum cuprate (La2CuO4) powder by means of microwave-hydrothermal method

A technology of microwave hydrothermal method and lanthanum cuprate, applied in chemical instruments and methods, copper compounds, inorganic chemistry, etc., can solve problems such as easy sintering of products, poor safety performance, and time-consuming, so as to overcome uneven heating and improve Work efficiency and the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Get 50ml distilled water and add in the beaker, then add analytically pure lanthanum nitrate (La(NO) in the beaker 3 ) 3 ·6H 2 O) magnetic stirring makes concentration be the solution A of 0.6mol / L;

[0020] 2) Add analytically pure copper nitrate (Cu(NO 3 ) 3 ·3H 2 O) stirring and making copper nitrate concentration is solution B of 0.3mol / L;

[0021] 3) press citric acid (C 6 h 8 o 7 ·H 2 O) and metal cation sum are 3: 1, add analytically pure citric acid (C) in solution B in the mol ratio 6 h 8 o 7 ·H 2 O) stirring at normal temperature to obtain solution C;

[0022] 4) Add ammonia water with a mass percentage of 4% to solution C dropwise, adjust the pH to 3, and stir for 30 minutes to obtain solution D;

[0023] 5) Add solution D into the microwave hydrothermal reaction tank, and control the filling degree to 70%; after sealing the reaction tank, place it in a microwave hydrothermal instrument; control the hydrothermal temperature at 200°C, react fo...

Embodiment 2

[0027] 1) Get 45ml distilled water and add in the beaker, then add analytically pure lanthanum nitrate (La(NO) in the beaker 3 ) 3 ·6H 2 O) magnetic stirring makes concentration be the solution A of 0.5mol / L;

[0028] 2) Add analytically pure copper nitrate (Cu(NO3 ) 3 ·3H 2 O) stirring and making copper nitrate concentration is solution B of 0.5mol / L;

[0029] 3) press citric acid (C 6 h 8 o 7 ·H 2 O) and metal cation sum are 2.8: 1, and in solution B, add analytically pure citric acid (C 6 h 8 o 7 ·H 2 O) stirring at normal temperature to obtain solution C;

[0030] 4) Add ammonia water with a mass percentage of 3% to solution C dropwise, adjust the pH to 1.5, and stir for 10 minutes to obtain solution D;

[0031] 5) Add solution D into the microwave hydrothermal reaction tank, and control the filling degree to 80%; after sealing the reaction tank, place it in a microwave hydrothermal instrument; control the hydrothermal temperature at 160 ° C, react for 60 minu...

Embodiment 3

[0034] 1) Get 60ml distilled water and add in the beaker, then add analytically pure lanthanum nitrate (La(NO) in the beaker 3 ) 3 ·6H 2 O) magnetic stirring makes concentration be the solution A of 0.7mol / L;

[0035] 2) Add analytically pure copper nitrate (Cu(NO 3 ) 3 ·3H 2 O) stirring and making copper nitrate concentration is solution B of 0.4mol / L;

[0036] 3) press citric acid (C 6 h 8 o 7 ·H 2 O) and metal cation sum are 3.8: 1, the mol ratio adds analytically pure citric acid (C in solution B) 6 h 8 o 7 ·H 2 O) stirring at normal temperature to obtain solution C;

[0037] 4) Add ammonia water with a mass percentage of 5% to solution C dropwise, adjust the pH to 5, and stir for 120 minutes to obtain solution D;

[0038] 5) Add solution D into the microwave hydrothermal reaction tank, and control the filling degree to 60%; after sealing the reaction tank, place it in the microwave hydrothermal instrument; control the hydrothermal temperature at 220 ° C, rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com