Gas tourill used for processing garbage

A technology for gas absorption and garbage treatment, applied in the direction of using liquid separation agent, dispersion particle separation, chemical instruments and methods, etc., can solve problems such as inability to eliminate peculiar smell, poor adsorption effect, corrosion of equipment, etc., and achieve no leakage of peculiar smell, adsorption And the effect of thorough purification and elimination of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

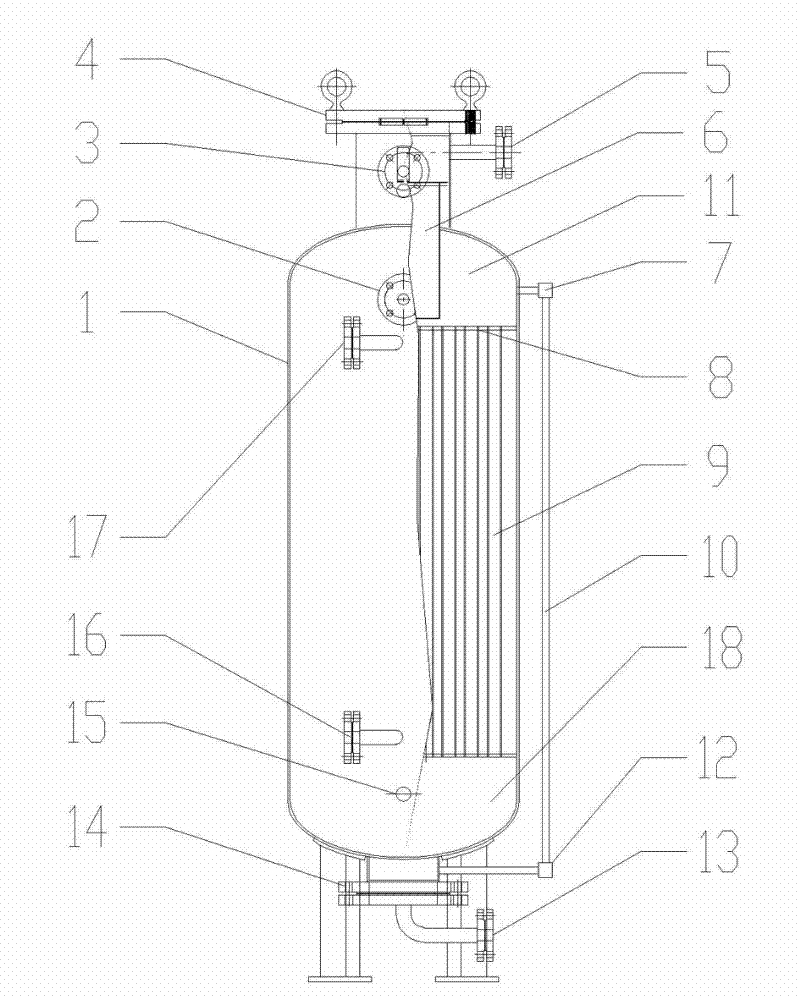

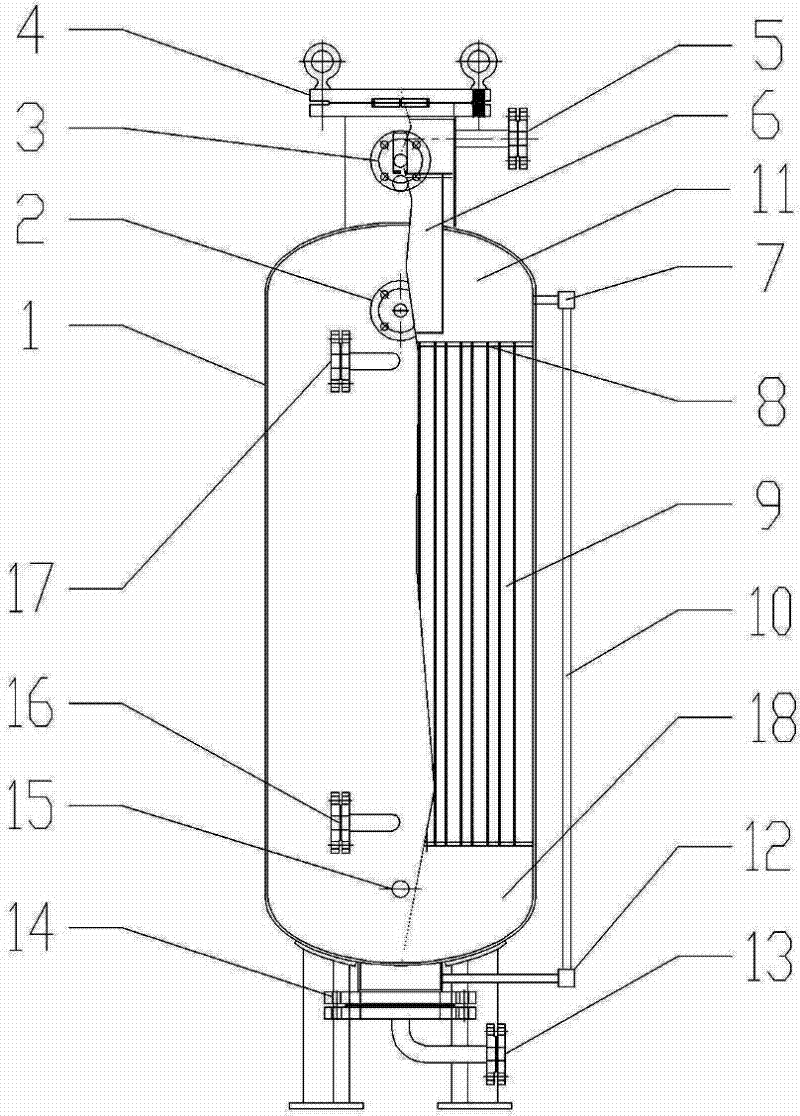

[0010] Such as figure 1 As shown, the present invention comprises a gas absorption tank body 1, and the gas absorption tank body 1 adopts acid and alkali-resistant 316L stainless steel material while its inner wall adopts a corrosion-resistant coating, which can effectively prevent the equipment from being corroded, thereby prolonging the service life of the equipment. The upper and lower ends of the gas absorption tank body 1 are respectively provided with a movable flange blind plate 4 and a flange blind plate 14 under the tank, and the upper and lower parts of the gas absorption tank body 1 are the upper lye warehouse 11 and the lower lye tank. Storehouse 18, the lower lye storehouse 18 is provided with an acid gas inlet 15, and the upper lye storehouse 11 is provided with a gas outlet 5 and an lye inlet 3, injecting alkaline liquid from the lye inlet 3 and spraying in a circular manner High-temperature gas, between the upper lye storehouse 11 and the lower lye storehouse 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com