Hydrogel containing coenzyme Q10, and cataplasm prepared by hydrogel

A technology of hydrogel and preparation, applied in the field of preparation carrier form of coenzyme Q10, can solve the problems of oxidation and decomposition, great influence on product quality and use effect, and decrease in content of coenzyme Q, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

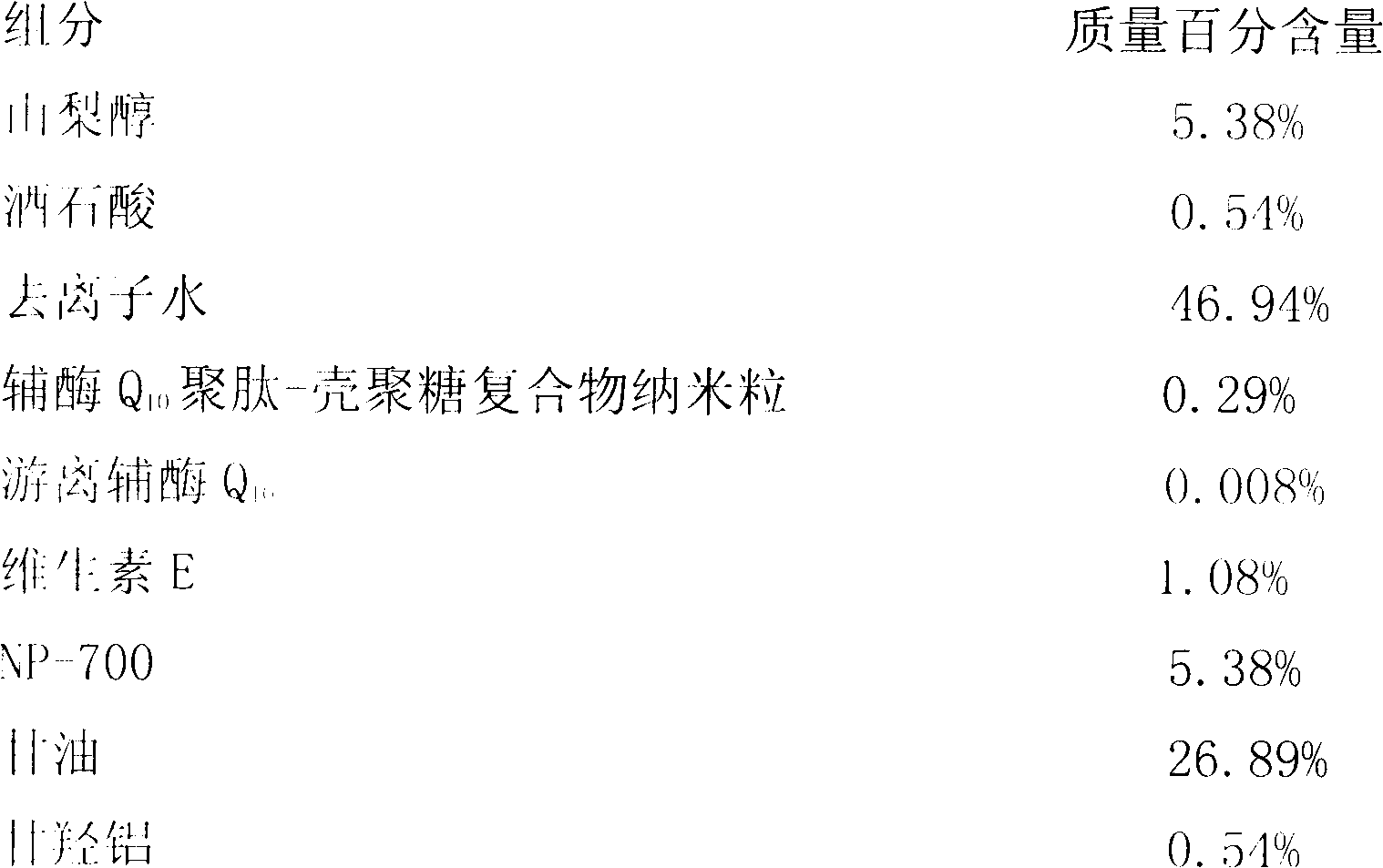

[0063] Preparations Containing Coenzyme Q 10 Nanoparticle hydrogel and cataplasm containing the hydrogel

[0064] In this example, the preparation containing Q 10 The hydrogel and cataplasm of polypeptide-chitosan composite nanoparticles were taken as an example to prepare coenzyme Q 10 A hydrogel of nanoparticles and a cataplasm containing the hydrogel will be described.

[0065] Coenzyme Q is prepared in this embodiment 10 The method for the polypeptide-chitosan composite nanoparticle can refer to CN101530394B.

[0066] First prepare the coenzyme Q-containing 10 Polypeptide-chitosan composite nanoparticles. The main auxiliary material used in the preparation of nanoparticles in the present invention is poly(L-glutamic acid-γ-benzyl ester)-polyethylene glycol block copolymer (PBLG-b-PEG), and its preparation method is as follows:

[0067] 2.5 mg of PBLG-b-PEG block copolymer and 3 mg of coenzyme Q 10 The mixture was dissolved in 25 mL of dimethylformamide: tetrahydrofu...

Embodiment 2

[0084] Preparations Containing Coenzyme Q 10 Hydrogel of flexible nano liposome and cataplasm containing the hydrogel.

[0085] This example uses egg yolk lecithin as the main membrane material rice to prepare coenzyme Q 10 Flexible nanoliposome, its preparation method is as follows: Weigh respectively 2.25g egg yolk lecithin, 0.36g cholesterol, 1.62g Tween 80, place in 250mL round bottom flask, add 20mL ether to make it dissolve, then the round bottom The flask was connected to a rotary decompression evaporator, and evaporated under reduced pressure for 30 minutes to remove the organic solvent therein until the dry lipid film was deposited on the wall of the bottle, and then 5 mL of ether was added to the round-bottomed flask, and the round-bottomed flask was shaken until it was deposited on the The dry lipid film on the wall of the flask was completely peeled off and dissolved. Then accurately weigh 30mg of coenzyme Q 10 and 0.36g sodium cholate, add 10mL deionized water,...

Embodiment 3~7

[0090] Coenzyme Q selected in the hydrogel described in Examples 3-7 and the cataplasm containing the hydrogel 10 The flexible nanoliposome is the same as in Example 2.

[0091]

[0092]

[0093] Coenzyme Q described in the above-mentioned Examples 3-7 10 Coenzyme Q contained in flexible nanoliposomes in embedded and free states 10 The content of the above-mentioned companies were respectively carried out, the results are as follows:

[0094] coenzyme Q 10 content Example 3 Example 4 Example 5 Example 6 Example 7 Embedded Coenzyme Q 10 content 0.05% 0.05% 0.05% 0.063% 0.063% free coenzyme Q 10 content 0.061% 0.061% 0.061% 0.077% 0.077% total coenzyme Q 10 content 0.111% 0.111% 0.111% 0.14% 0.14%

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com