Metal caloric low-temperature dry distillation process for long flame coal or lignite

A technology of metal heat and long-flame coal, which is applied in the direction of direct heating dry distillation, special form dry distillation, petroleum industry, etc., can solve the problems of high product added value, low heat recovery, low comprehensive efficiency, etc., so as to improve utilization rate and Utilization value, no consumption of water resources, high value-added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

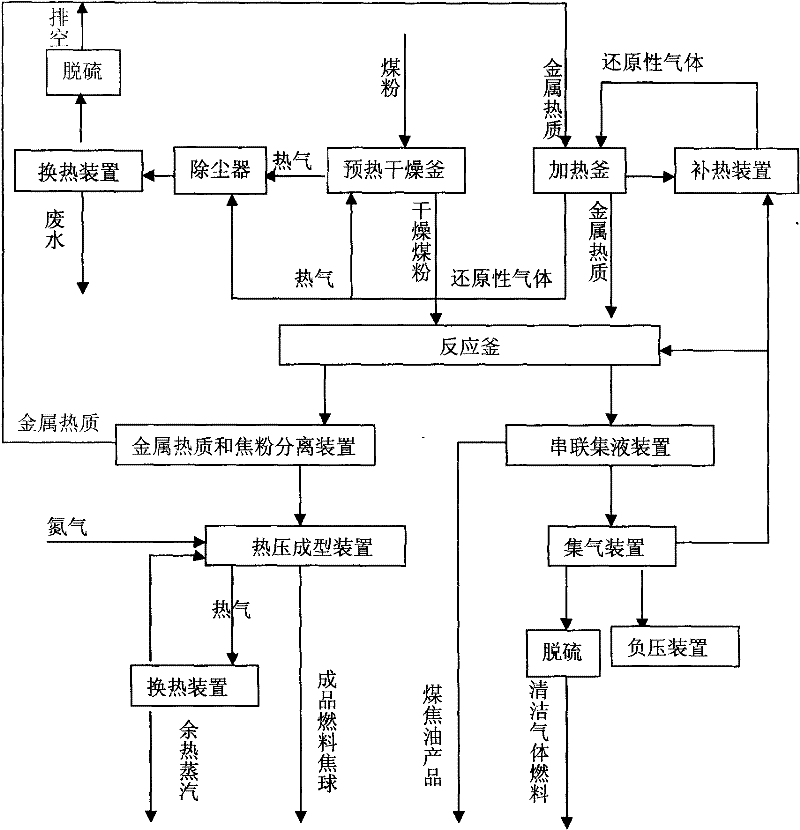

Method used

Image

Examples

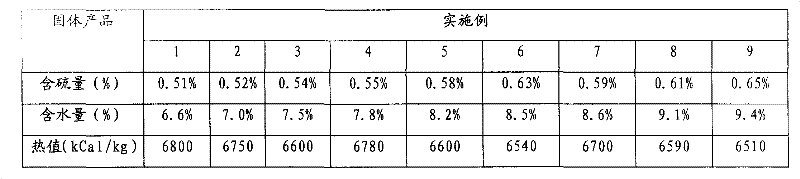

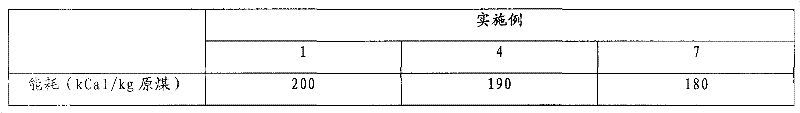

Embodiment 1

[0027] Under normal pressure, the tail gas reducing gas is used to dry and heat the pulverized coal, the heating temperature is controlled at 120-180 degrees, the pulverized coal is preheated and dried, and the particle size of the coal particles is below 2mm. The heating temperature of the metal heat mass is controlled at 730 degrees, and the metal heat mass is a cast steel ball. According to the weight ratio of coal powder and metal thermal mass 1:10, it is sent into the reaction kettle in batches, the temperature of the reaction kettle is kept at 650 degrees, the atmosphere is reduced, and the reaction time is 90 seconds. During the dry distillation process, the volatile substances are extracted by negative pressure and collected in six stages. Coke powder and metal heat are separated by sieving. The coke powder is formed by hot pressing, and the coke ball is cooled by nitrogen gas to reduce the temperature to below 160 degrees Celsius. The sieved metal thermal mass, with...

Embodiment 2

[0029] Under normal pressure, the tail gas reducing gas is used to dry and heat the pulverized coal, the heating temperature is controlled at 120-180 degrees, the pulverized coal is preheated and dried, and the particle size of the coal particles is below 2mm. The heating temperature of the metal heat mass is controlled at 680 degrees, and the metal heat mass is a cast steel ball. According to the weight ratio of coal powder and metal thermal mass 1:15, send them into the reaction kettle in batches, keep the temperature of the reaction kettle at 650 degrees, reduce the atmosphere state, and the reaction time is 60 seconds. During the dry distillation process, the volatile substances are extracted by negative pressure and collected in six stages. Coke powder and metal heat are separated by sieving. The coke powder is formed by hot pressing, and the coke ball is cooled by nitrogen gas to reduce the temperature to below 160 degrees Celsius. The sieved metal thermal mass, with w...

Embodiment 3

[0031] Under normal pressure, the tail gas reducing gas is used to dry and heat the pulverized coal, the heating temperature is controlled at 120-180 degrees, the pulverized coal is preheated and dried, and the particle size of the coal particles is below 2mm. The heating temperature of the metal heat mass is controlled at 630 degrees, and the metal heat mass is a cast steel ball. According to the weight ratio of coal powder and metal thermal mass 1:20, send them into the reaction kettle in batches, keep the temperature of the reaction kettle at 650 degrees, reduce the atmosphere state, and the reaction time is 30 seconds. During the dry distillation process, the volatile substances are extracted by negative pressure and collected in six stages. Coke powder and metal heat are separated by sieving. The coke powder is formed by hot pressing, and the coke ball is cooled by nitrogen gas to reduce the temperature to below 160 degrees Celsius. The sieved metal thermal mass, with w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com