Bacterial cellulose conductive thin film and preparation method thereof

A technology of bacterial cellulose and composite film, which is applied in the field of bacterial cellulose conductive composite film and its preparation, can solve the problems of low electrical conductivity and the like, achieve high electrical conductivity, facilitate industrial production, and simplify the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of bacterial cellulose conductive composite film of the present invention comprises the following steps:

[0032] ① Thermally shock expandable graphite at a high temperature of 900-1200°C for 15-25 seconds to obtain expanded graphite;

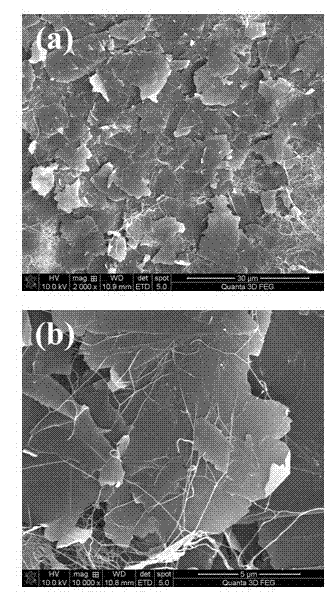

[0033] ② The prepared expanded graphite was stirred in absolute ethanol at high speed for 20-60 minutes, then ultrasonically treated for 10-14 hours, filtered, washed, and dried at 80-120°C to obtain nano-graphite microflakes;

[0034] ③Put nano-graphite flakes into the dispersion medium to form nano-graphite flakes solution;

[0035] ④ Ultrasonic treatment of the nanographite microflake solution for 2-3 hours to obtain a suspension of uniformly dispersed nanographite microflakes;

[0036] ⑤ Add bacterial cellulose wet film to the suspension of nano-graphite microflakes, and perform ultrasonic treatment for 3-9 hours;

[0037] ⑥Take out the treated bacterial cellulose wet film, rinse to remove residual dispersion...

Embodiment 1

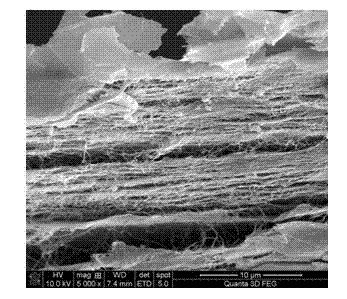

[0040]Expandable graphite (commercially available) was heat-shocked at 1000°C for 20 seconds to obtain expanded graphite; the obtained expanded graphite was subjected to high-speed shear stirring (2400r / min) in absolute ethanol for 30 minutes and then ultrasonically treated (80 kHz, 100 W) for 12 hours, filtered, washed, and dried at 80°C to obtain graphite nanosheet powder. The particle size of the obtained nano graphite flake powder is 3-20μm, the thickness is 20-80nm, the average particle size is about 15μm, the average thickness is about 50nm, it has a large diameter-thickness ratio of about 300, and the periphery is irregular. . Under normal temperature and pressure, put the nano-graphite micro-flakes into absolute ethanol to form an absolute ethanol solution containing 0.05wt% nano-graphite micro-flakes, and ultrasonicate at room temperature for 2 hours to obtain a uniformly dispersed nano-graphite micro-flakes. Suspend the ethanol solution, then add high-swellable bact...

Embodiment 2

[0043] Expandable graphite (commercially available) was heat-shocked at 900°C for 15 seconds to obtain expanded graphite; the resulting expanded graphite was subjected to high-speed shear stirring (2400r / min) in absolute ethanol for 20 minutes and then ultrasonically treated (80 kHz, 100 W) for 10 hours, filtered, washed, and dried at 100°C to obtain graphite nanosheet powder. Under normal temperature and pressure, put the nano-graphite micro-flakes into absolute ethanol to form an absolute ethanol solution containing 0.05wt% nano-graphite micro-flakes, and ultrasonicate at room temperature for 2 hours to obtain a uniformly dispersed nano-graphite micro-flakes. Suspend the ethanol solution, then add high-swelling bacterial cellulose wet film to it, and ultrasonically take it out for 6 hours at room temperature to obtain a finished bacterial cellulose conductive composite film with a thickness of about 38 microns. The bacterial cellulose film content in the composite film is mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com