Glass suitable for trough photo-thermal power generation heat collection tube

A solar-thermal power generation and trough-type technology, which is applied in the field of glass for trough-type solar-thermal power generation collector tubes, can solve problems such as surface blackening, furnace refractory erosion, and low clarification efficiency, and achieve long glass frit and high liquid The effect of finite viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

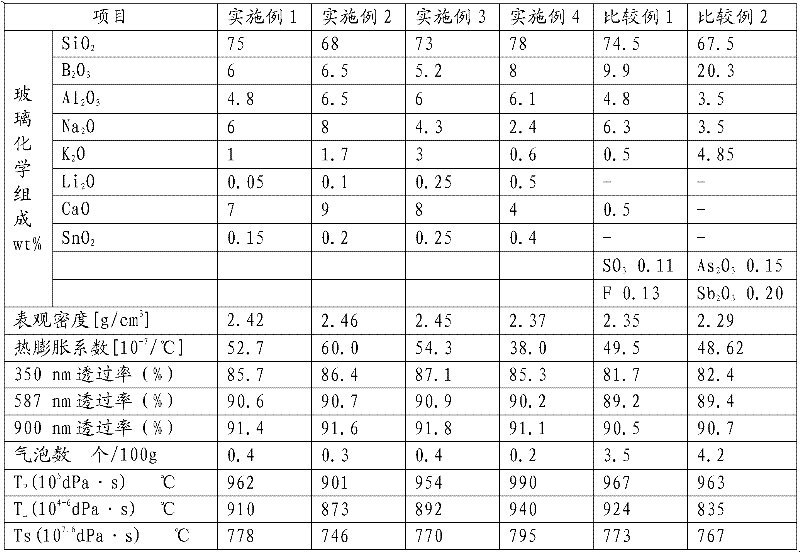

[0025] The present invention is described based on the embodiments, and Table 1 is the composition and performance of the embodiments of the present invention and comparative examples.

[0026] Glass chemical composition and performance list of the embodiment and comparative example of table 1

[0027]

[0028]

[0029] First, select the raw material according to the glass composition of Example 1 in Table 1, the raw material requirements, quartz sand (the 150 μm sieve is less than 1%, the 45 μm sieve is less than 30%, Fe 2 o 3 content less than 0.010wt%), aluminum hydroxide or aluminum oxide (average particle size 50μm), boric acid or borax (400μm sieve is less than 10%, 63μm sieve is less than 10%), calcium carbonate (average particle size 250μm ). Moreover, Fe in the glass raw material 2 o 3 Strictly controlled, the finished glass Fe 2 o 3 The content is less than 150PPm. The selected clarifying agent is tin oxide, and the amount of tin oxide is 0.15%, so that ...

Embodiment 2

[0045] Refer to Example 2 in Table 1 for the actual composition of the glass, use the same raw materials and raw material requirements as in Example 1, make the ingredients meet the glass composition in Table 1, and then use a platinum crucible to melt at 1560 ° C for 24 hours. After melting, the molten metal is hydraulically formed into the specified test product requirements, and then annealed to room temperature at 5°C / min after holding at 570°C for 1h. The basic properties of the samples are shown in Table 1.

[0046] On the whole, compared with Comparative Example, the glass of Example 1 has a better clarification effect, the number of bubbles per 100 grams of glass is less than 1, has a good spectral transmittance, has a moderate expansion coefficient, and can be applied to molybdenum metal It is sealed with Kovar alloy, and the wetting angle is 16°, which has excellent wetting performance. The anti-exposure performance and mechanical properties are better than those of...

Embodiment 3

[0048] The actual composition of the glass refers to Example 3 in Table 1, using the same raw materials and raw material requirements as in Example 1, and the amount of sodium nitrate is 1.0%, so that the ingredients meet the glass composition in Table 1, and then use a platinum crucible to melt at 1560 ° C for 24 Hour. After melting, the molten metal is hydraulically formed into the specified test product requirements, and then annealed to room temperature at 5°C / min after holding at 570°C for 1h. The basic properties of the samples are shown in Table 1.

[0049] On the whole, compared with the comparative example, the glass of Example 1 has a better clarification effect, the number of bubbles per 100 grams of glass is less than 1, and it has a good spectral transmittance. With a moderate expansion coefficient, it can be applied to the sealing of molybdenum metal and Kovar alloy, and the wetting angle is 17°, which is excellent in wetting performance. The anti-exposure perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com