Method for preparing highly-graphitized hollow carbon nanocapsules by using low-temperature reaction

A hollow nano, low-temperature reaction technology, applied in the direction of nanotechnology, can solve the problems of low graphitization degree of hollow nano carbon spheres, low yield of hollow nano carbon spheres, complicated operation process, etc., to achieve low price, high yield, The effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

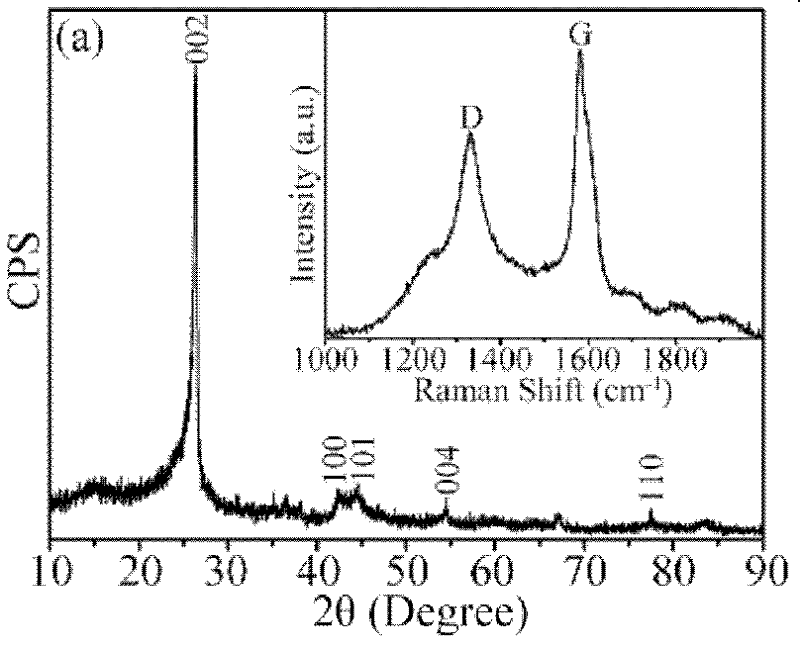

Image

Examples

Embodiment 1

[0029] Hollow carbon nanospheres were prepared by reacting calcium carbide and aluminum chloride hexahydrate. Weigh 11.0g of calcium carbide and 8.9g of aluminum chloride hexahydrate with a balance, and put them into a stainless steel reaction kettle. After the reaction kettle is tightly sealed, heat it in a heating furnace to about 500°C. After keeping the temperature for 5 hours, close the heating furnace to make the reaction The kettle was naturally cooled to room temperature in the furnace. The reaction product is divided into two layers, the upper layer is a spongy black substance, and the lower layer is a gray mixture. The product is washed with concentrated hydrochloric acid and deionized water. During the cleaning process, the black product floats on the liquid surface. The black powder obtained after drying for 8 hours was 2.11 g.

Embodiment 2

[0031] Nano-carbon hollow spheres were prepared by reacting calcium carbide and aluminum chloride hexahydrate. Weigh 11.0g of calcium carbide and 8.9g of aluminum chloride hexahydrate with a balance, and put them into a stainless steel reactor. After the reactor is sealed tightly, heat it in a heating furnace to about 250°C. After keeping the temperature for 5 hours, close the heating furnace to make the reaction The kettle was naturally cooled to room temperature in the furnace. The reaction product is divided into two layers, the upper layer is a spongy black substance, and the lower layer is a gray mixture. The product is washed with concentrated hydrochloric acid and deionized water. During the cleaning process, the black product floats on the liquid surface. The black powder obtained after drying for 6 hours was 0.41 g.

Embodiment 3

[0033] Nano-carbon hollow spheres were prepared by reacting calcium carbide and aluminum chloride hexahydrate. Weigh 11.0g of calcium carbide and 8.9g of aluminum chloride hexahydrate with a balance, and put them into a stainless steel reaction kettle. After the reaction kettle is tightly sealed, heat it in a heating furnace to about 250°C. After keeping the temperature for 1 hour, close the heating furnace to make the reaction The kettle was naturally cooled to room temperature in the furnace. The reaction product is divided into two layers, the upper layer is a spongy black substance, and the lower layer is a gray mixture. The product is washed with concentrated hydrochloric acid and deionized water. During the cleaning process, the black product floats on the liquid surface. The black powder obtained after drying for 8 hours was 0.32 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com