Vacuum insulation plate with high strength and long service life

A vacuum insulation panel, long-life technology, applied in heat exchange equipment, pipeline protection through thermal insulation, thermal insulation, etc., can solve the problems of thermal conductivity recovery, physical and chemical damage, high fiber resilience, etc., to achieve ultra-long life, Good mechanical strength, the effect of increasing penetration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below according to example the present invention is further described:

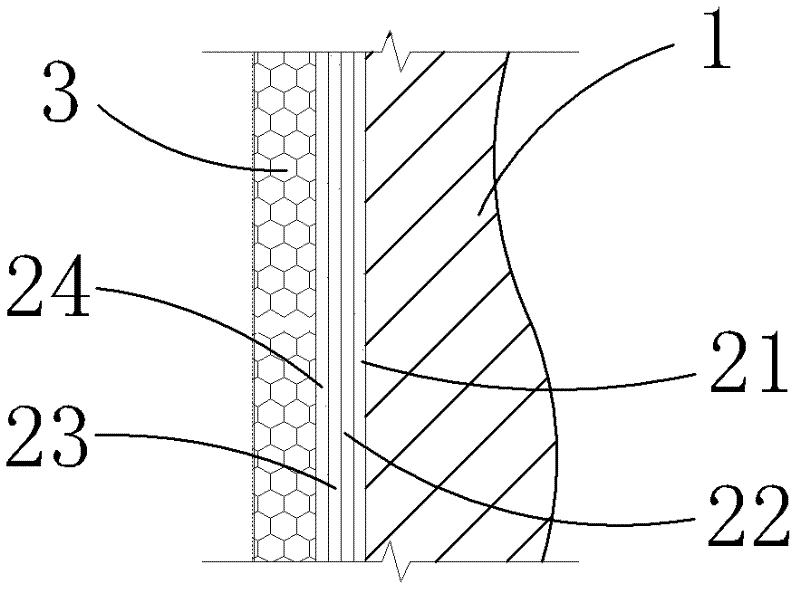

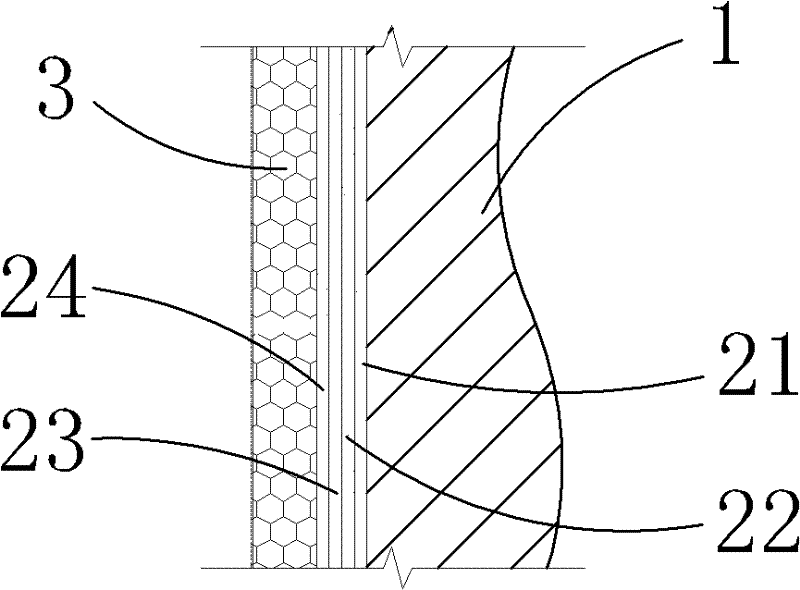

[0017] Such as figure 1 with figure 2 As shown, a high-strength and long-life vacuum insulation panel includes a core material 1, a high-performance barrier film 2 and a plastic protective layer 3, the high-performance barrier film 2 is coated on the outer surface of the core material 1, and the plastic protective layer 3 coated on the outer surface of the high performance barrier film 2.

[0018] The core material 1 can generally adopt perlite, turpentine, obsidian, white carbon black, pearlite, or diatomite with a particle size of 50-2000 mesh, and the core material 1 adopts perlite with a particle size of 50-1500 mesh , pitch rock, obsidian, white carbon black, pearlite, diatomaceous earth or wollastonite.

[0019] Its main component is silicon dioxide containing 50-90%, the rest is Al 2 o 3 , Fe 2 o 3 , CaO, MgO, K 2 O, Na 2 O, or P 2 o 5 of inorganic impurities.

[0020] Such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com