Deodorization composite biological stuffing as well as preparation method and application of the same

A biological filler and microorganism technology, applied in the field of deodorizing composite biological filler and its preparation, can solve the problems of lack of nutrients, high cost, perishable plant fibers, etc., achieve stable continuous use time, solve processing problems, and good biological adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Preparation of biocomposite fillers.

[0020] The filler main body is a mixture of 75% calcium carbonate, 2.5% diammonium hydrogen phosphate, 20% bark powder and 2.5% urea.

[0021] Binder by weight percentage, ethylene / vinyl acetate 30%, Na 2 O nSiO 2 / K 2 O nSiO 2 For a mixture of 70%, the total amount of binder is 30% of the filler body by weight.

[0022] Mix the filler body in the container for 10 minutes, add the binder, and then add water that is 80% by weight of the filler body. Put the mixture into a mold and extrude it into pellets, and then dry it at 90°C for 1 hour for later use.

[0023] 2. Fermentation of deodorizing compound bacterial agent.

[0024] (1) Prepare liquid medium. The liquid culture medium is an aqueous solution containing 0.5% of glucose, 0.5% of beef extract, 0.5% of sodium thiosulfate, 0.2% of potassium dihydrogen phosphate, and 0.02% of magnesium chloride (containing 6 parts of crystal water) by weight percentage, and does not ...

Embodiment 2

[0029] 1. Preparation of biocomposite fillers.

[0030] The main body of the filler is a mixture of 80% calcium carbonate, 5% diammonium hydrogen phosphate, 10% bark powder and 5% soybean meal powder in terms of weight percentage.

[0031] The binder is 100% ethylene / vinyl acetate by weight percentage, and the total amount of the binder is 20% of the filler main body by weight percentage.

[0032] The filler body was mixed in the container for 15 minutes, the binder was added, and then 70% water by weight of the filler body was added. Put the mixture into a mold and extrude it into a cylindrical shape, and dry it at 60°C for 5 hours before use.

[0033]2. Fermentation of deodorizing compound bacterial agent.

[0034] (1) Prepare liquid medium. The liquid medium is an aqueous solution containing 1.0% of glucose, 1.0% of beef extract, 0.5% of sodium thiosulfate, 0.2% of potassium dihydrogen phosphate, and 0.02% of magnesium chloride (containing 6 parts of crystal water) by we...

Embodiment 3

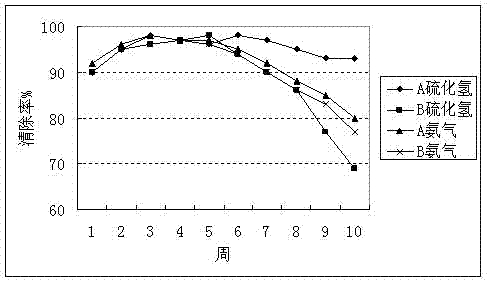

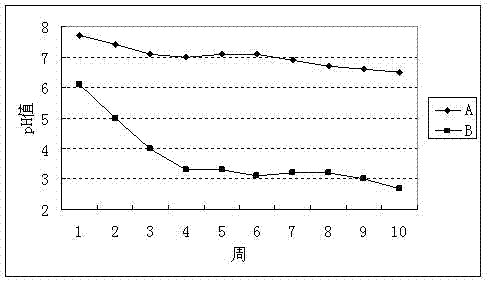

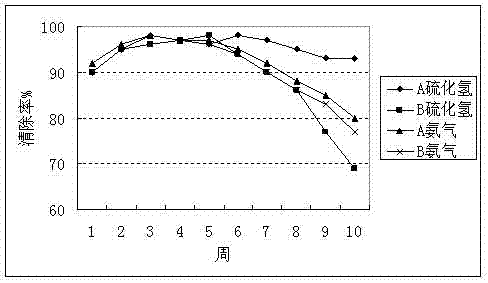

[0039] Put equal volumes of the biological composite filler (biological filter bed A) and bark (biological filter bed B) into two identical biological filter bed test devices, and adopt natural stacking method without compaction. The filler used in A is prepared according to the method described in Example 2, and the deodorizing composite bacterial agent (prepared according to the method described in Example 2) that accounts for 0.3% of the total volume of the biofilter tank filler is added; the bark used in B does not add any deal with. The air flow rate during the test is 1m 3 / h, containing hydrogen sulfide 500mg / m 3 , Ammonia 500mg / m 3 , continuously fed for 10 weeks, the removal effect of the two filter beds on hydrogen sulfide and ammonia and the pH value of the system are shown in figure 1 and figure 2 .

[0040] Compared with the biological filter bed of group B using only bark, the hydrogen sulfide removal effect of group A using the biological composite filler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com