Trithiocarbonate compound containing ethylene, preparation method and application thereof

A technology of trithiocarbonates and compounds, which is applied in the field of preparation of trithiocarbonates, can solve the problems of difficulty in obtaining continuous structure membrane materials, difficulty, and restrictions on the promotion and application of new membrane materials, and achieve good application prospects, Easy to adjust, suitable for a wide range of monomer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Preparation of 2-(dodecyl trithiocarbonate group) propionic acid

[0058] Mix 10 grams of sodium hydroxide, 5.4 grams of tetrapropylammonium bromide and 10 grams of water uniformly at room temperature, add them to a 500 mL three-necked round-bottomed flask with a stirring bar and stir, and protect the reaction system with nitrogen gas. 60mL of dodecanethiol was added dropwise into a three-necked round-bottomed flask with a syringe, and the reaction was continued for 0.5 hours after the dropwise addition; During the dropwise addition, it can be observed that white flocs are generated and gradually increase. After the dropwise addition, the reaction is kept for 0.5 hours, and then ice bathed. After the temperature of the material in the reactor was completely lowered to 0°C, 15 mL of carbon disulfide was added dropwise into the flask with a syringe, and the reaction solution turned into a yellow turbid solution at this time. After keeping the reaction for 0.5 hour, 3...

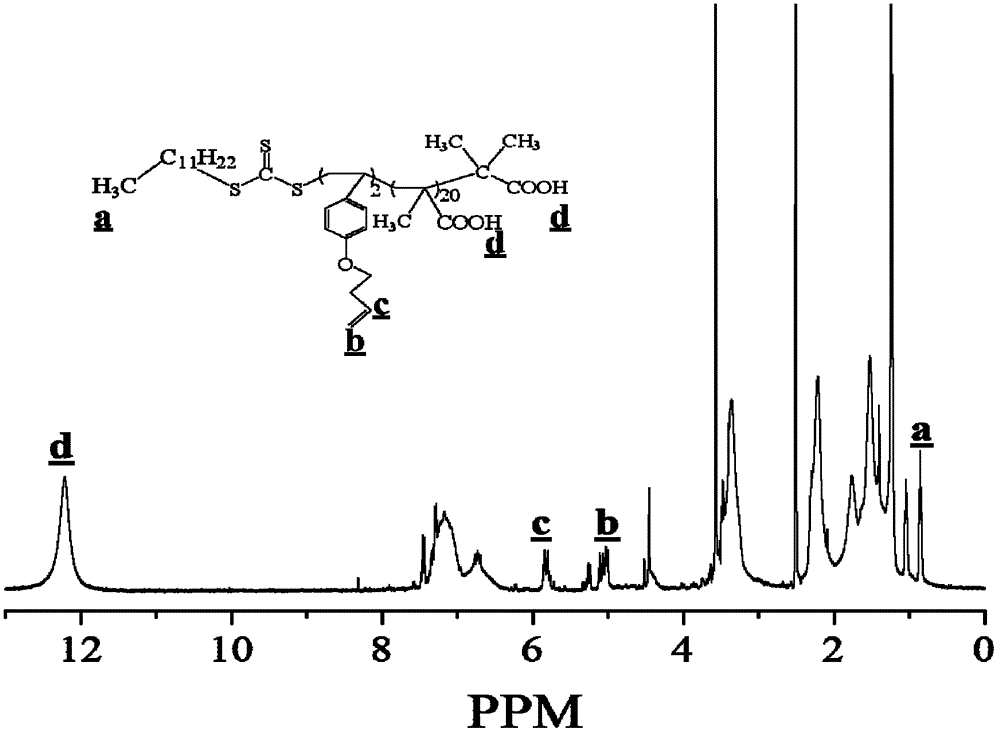

Embodiment 2

[0063] (1) The preparation of 2-(dodecyl trithiocarbonate group) propionic acid is the same as in Example 1.

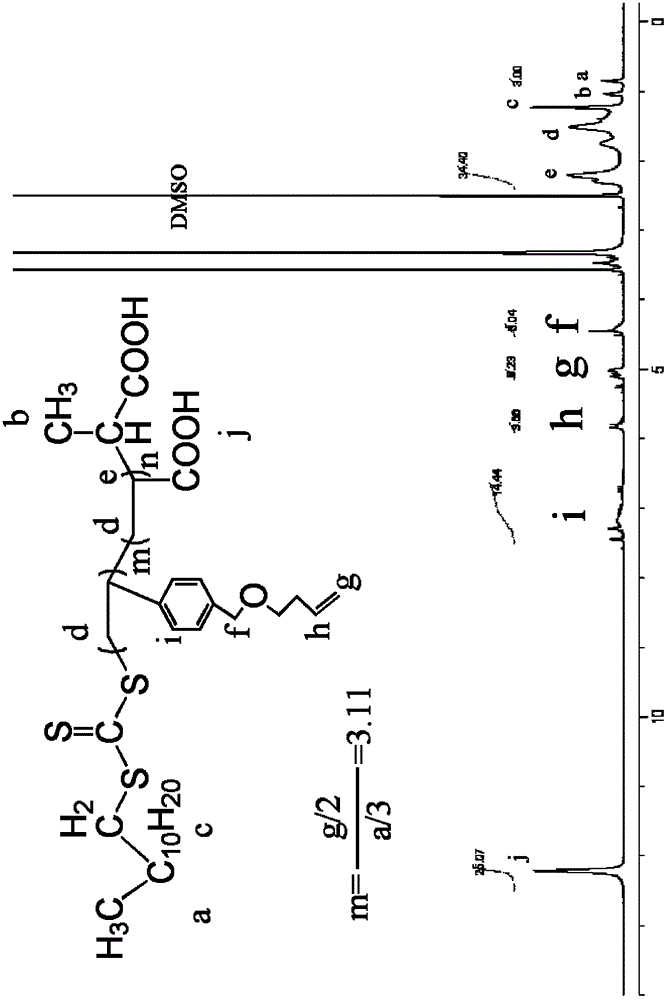

[0064] (2) Preparation of vinyl-containing trithiocarbonate compounds

[0065] In a 250mL three-necked flask equipped with a reflux condenser, a nitrogen inlet, and a feed port, drop the following reagents: 5 grams of dioxane, 2-(dodecyltrithiocarbonate) propane prepared in step (1) Acid 0.3 g, azodicyanovaleric acid 0.025 g and N, N'-dimethylacrylamide 4.0 g. After passing high-purity (purity: 99.99%) nitrogen to the above device for 1 hour, immerse in a 70°C water bath, and after 10 hours, an intermediate product was obtained; continue to add 1 gram of dioxane and azodicyanovaleric acid to the three-necked flask 0.025 g, 0.97 g of a dienyl double bond-containing monomer with the structure of formula 20 was continued to react in a water bath at 80° C. for 12 hours, then the temperature was lowered, and the reaction was stopped to obtain the product. The product was...

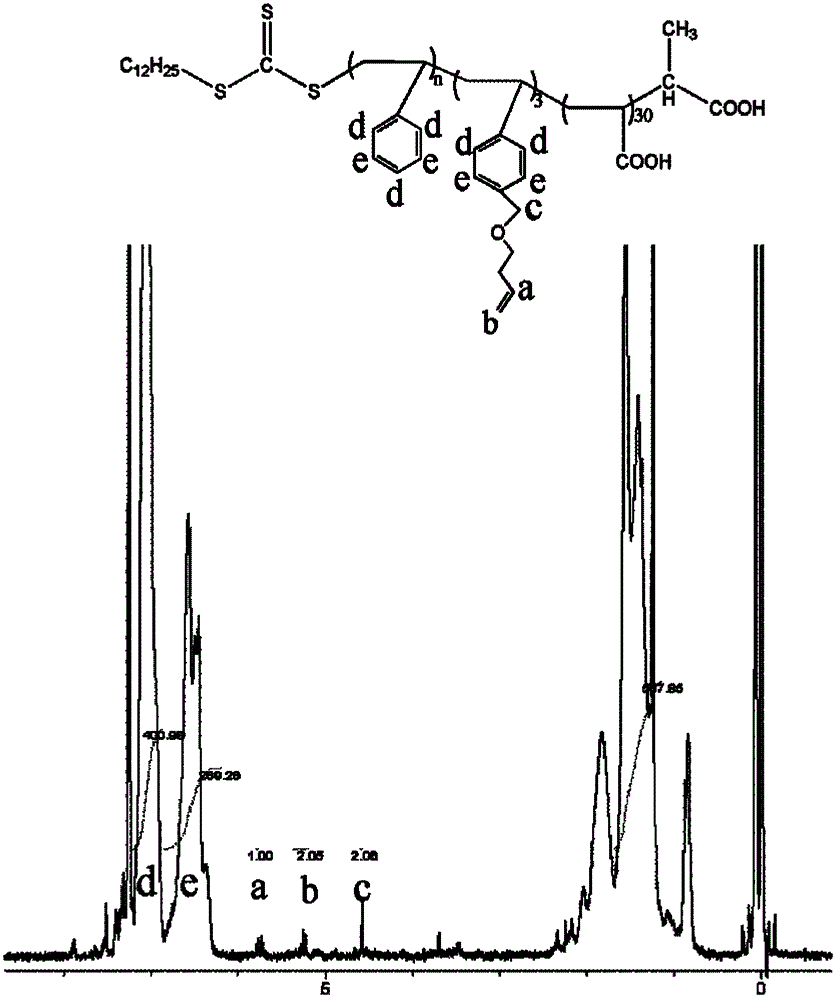

Embodiment 3

[0068] (1) Preparation of 2-(dodecyl trithiocarbonate group) isobutyric acid

[0069] Add 202.4 grams of mercaptan, 16.14 grams of methyl trioctyl ammonium chloride and 482.06 grams of acetone into a three-necked flask with a reflux condensing device, the temperature of the water bath is 10 ° C, magnetic stirring, nitrogen, and deoxygenation for 20 minutes Add dropwise the sodium hydroxide aqueous solution of 40 grams (mass concentration is 50%), add in 20 minutes, continue reaction 15 minutes; Add dropwise the acetone mixed solution of the carbon disulfide of 76.1 grams and 98.74 grams, after adding in 20 minutes, Continue to react for 10 minutes; Add 179.07 grams of chloroform, then dropwise add 200 grams of sodium hydroxide aqueous solution (mass concentration is 50%), dropwise in 0.5 hours, stir and react for 12 hours; Add 1500 grams of deionized water, Then add 109.5 grams of concentrated hydrochloric acid (mass concentration is about 37%); blow nitrogen, stir vigorously,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com