A pigment coated paperboard adapted for sterilizable packages

A technology for coating cardboard and pigments, applied in packaging paper, pigmented coatings, packaging, etc., can solve the problems of not improving hydrophobicity and achieve good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

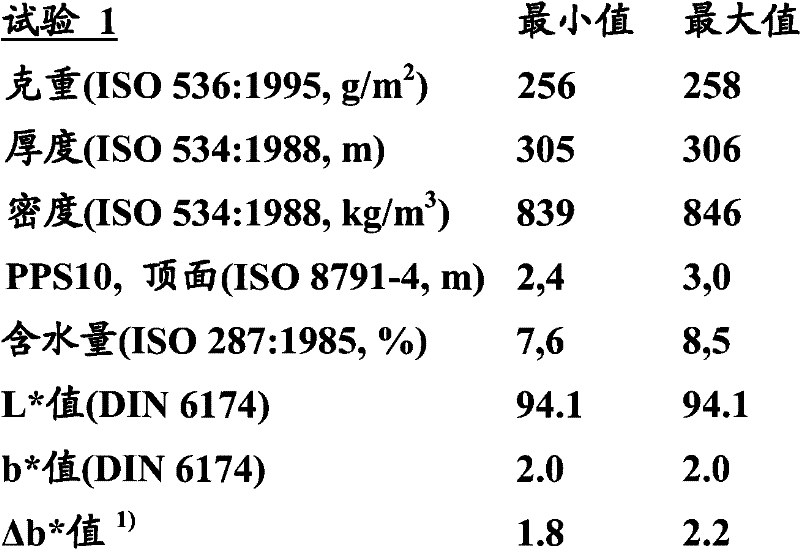

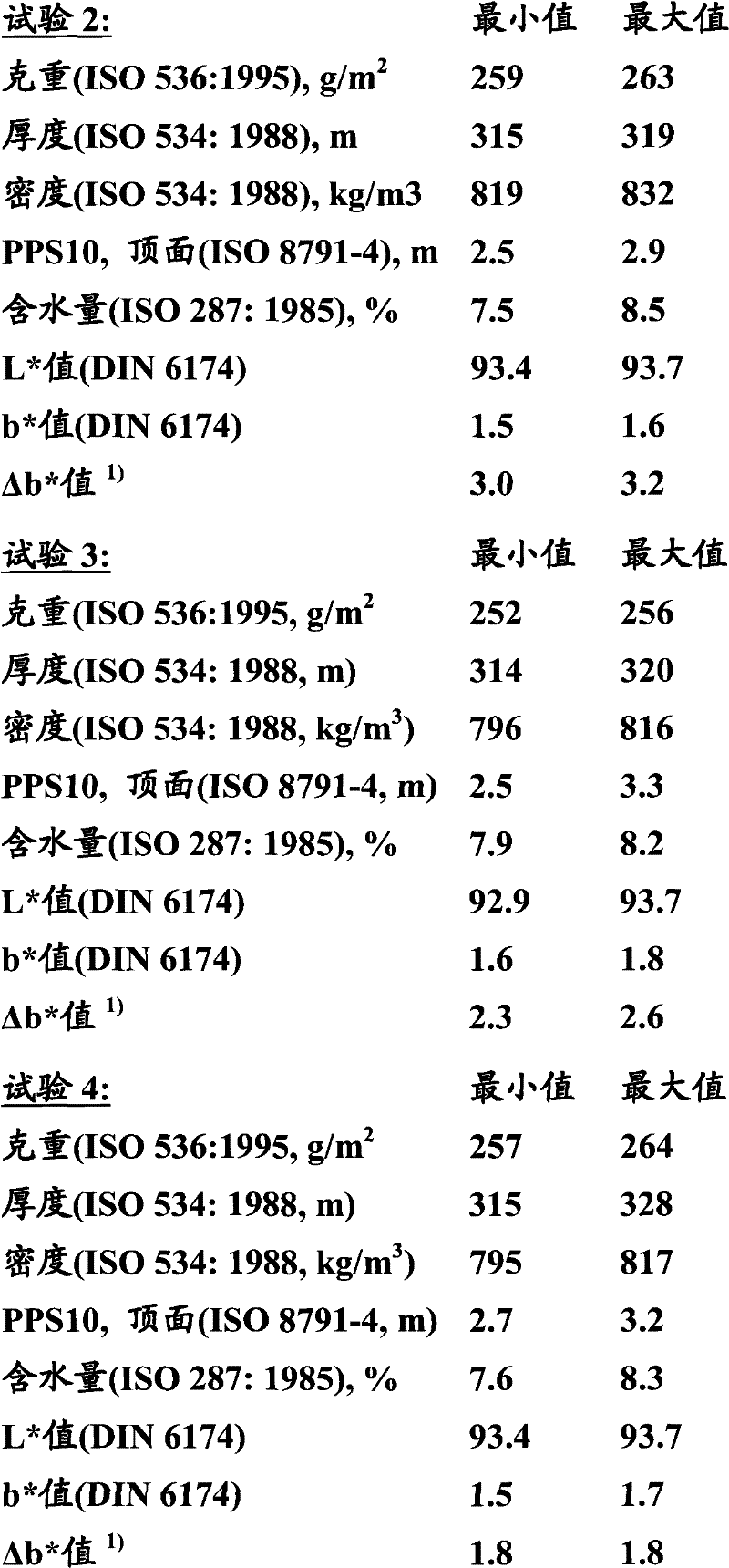

Examples

Embodiment Construction

[0038] The invention is now described by the illustration of embodiments given by way of example only, with the understanding that these embodiments do not constitute a limitation of the scope of protection defined in the claims.

[0039] The pigment-coated paperboard of the present invention can be produced as a two-ply (two-ply) board with a top layer of bleached kraft pulp (a mixture of 50% softwood and 50% by weight hardwood pulp) and bleached or unbleached softwood Bottom layer of pulp. As an alternative to the bottom layer, it is possible to combine bleached / unbleached softwood pulp with bleached or unbleached hardwood pulp, or even to use only bleached / unbleached hardwood pulp. A portion (eg 50% by weight) of the softwood pulp can be treated in the HC refiner to increase the flexibility of the fibres, which is believed to reduce the tendency to crack during board conversion. The beating level of all three pulps should be at least 21° SR.

[0040] The bleached top laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com