LED (Light Emitting Diode) module based on ceramic-based PCB (Printed Circuit Board) and manufacturing process thereof

A technology of LED modules and PCB boards, which is applied in the direction of printed circuits connected with non-printed electrical components, printed circuit components, electrical components, etc. Poor performance and other problems, to achieve the effect of high transmittance, low cost, and improve light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

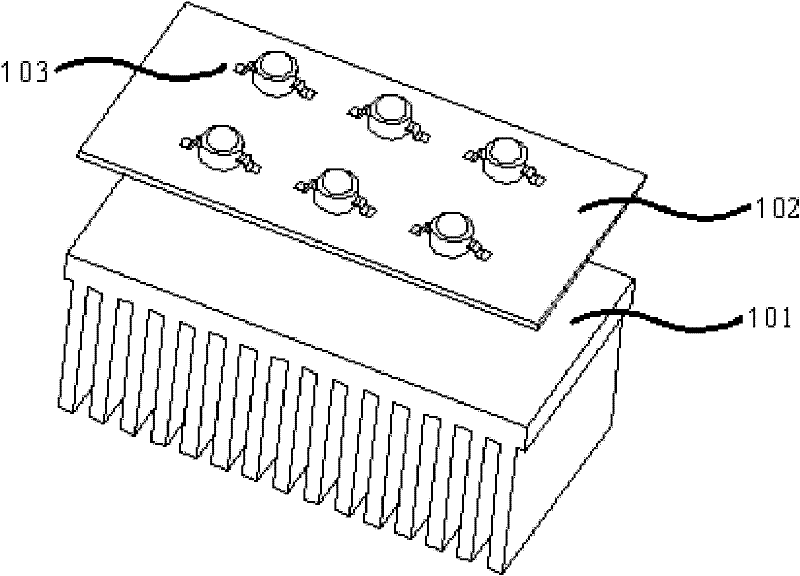

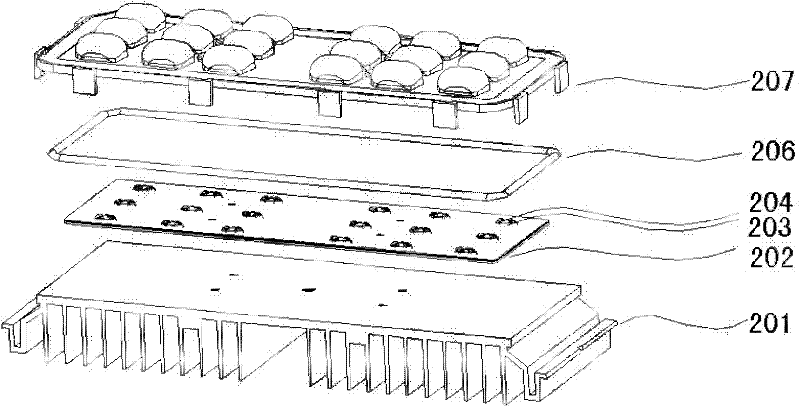

[0107] like figure 2 As shown, an LED module includes: a heat sink 201 , a ceramic base PCB 202 , an LED chip 203 , an LED open circuit protector 204 , encapsulating colloid, sealing silica gel 206 , and a lens module 207 .

[0108] The LED open circuit protector 204 is connected in parallel with the LED chip 203, and its function is for open circuit protection and anti-static. The LED open circuit protector 204 of this embodiment adopts a Zener diode.

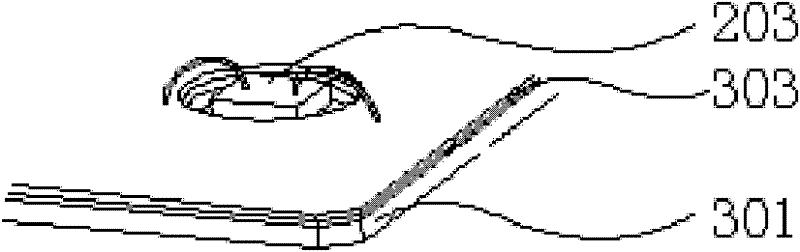

[0109] The ceramic-based PCB 202 can also be a high-thermal-conductivity ceramic-based PCB, which includes a ceramic substrate 301 and an electrical layer 303 .

[0110] like image 3 , Figure 4 As shown, the ceramic base PCB contains fired unpenetrated dimples, and a fired electrical layer 303 . The electrical layer 303 is the positive and negative electrodes and electrical connection lines sintered on the ceramic substrate 301 . The LED chip 203 is directly loaded on the base of the unpenetrated pit, and is welded to ...

Embodiment 2

[0131] The ceramic base PCB 202 of this embodiment is not provided with a pit for installing the LED chip 203 , but the LED chip 203 is directly covered on the ceramic substrate 301 of the ceramic base PCB 202 . The surface of the ceramic substrate 301 where the LED chip 203 is covered is a brightened smooth surface, and the brightened smooth surface may further have a coated mirror surface. The remainder of this embodiment is the same as in Embodiment 1.

[0132] A manufacturing process of an LED module based on a ceramic-based PCB board 202, the steps are as follows:

[0133] (1) sintering electrical layer 303 on ceramic base PCB board 202, described electrical layer 303 is positive and negative electrodes and electrical connecting circuit sintered on ceramic substrate 301;

[0134] (2) The position for installing the LED chip 203 on the ceramic-based PCB board 202 is polished into a reflective smooth surface through a mirror brightening process, or coated with silver on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com