Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of reduced on-resistance, increased on-resistance, and increased drive current of DEMOS devices, etc., to achieve leakage The source on-resistance value and drive current are kept stable and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

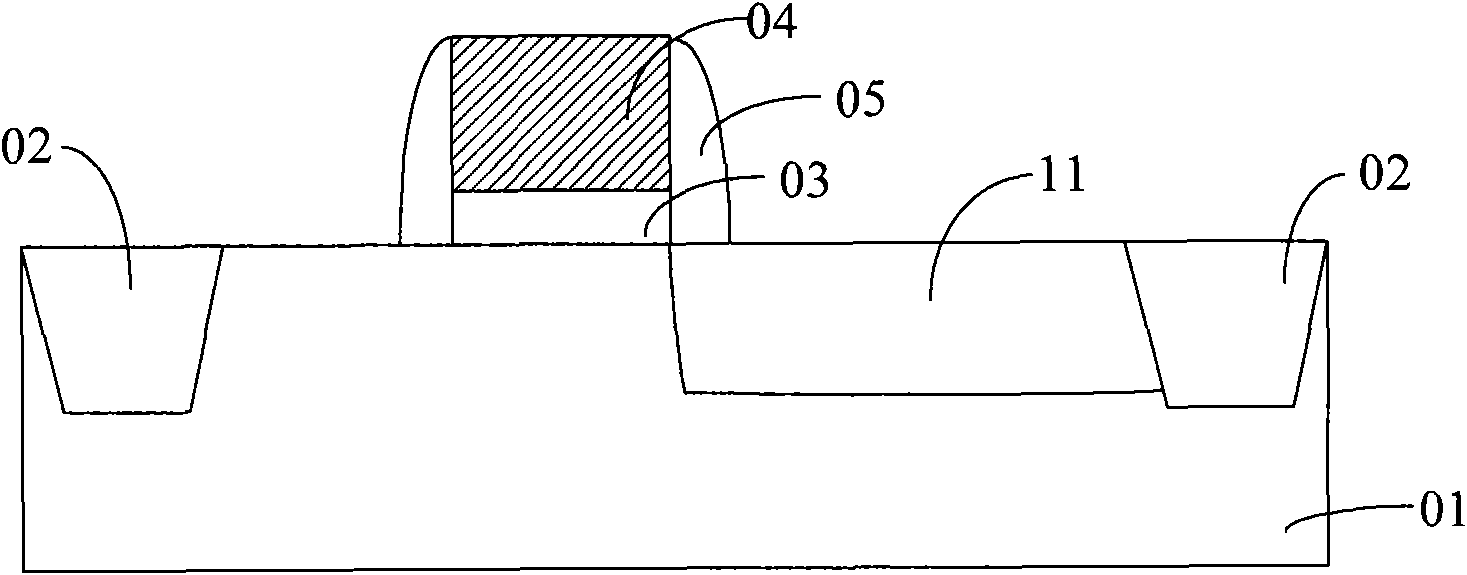

[0044] The present invention covers part of the drain lightly doped region by the gate structure, and uses the gate structure as a mask to perform ion implantation in the drain heavily doped region or the source heavily doped region, so that the drain heavily doped region or the source heavily doped region The distance between the impurity region and the side wall is kept stable, and thus the drain-source on-resistance value and the driving current are kept stable, thereby improving the stability of the manufacturing process of the semiconductor device.

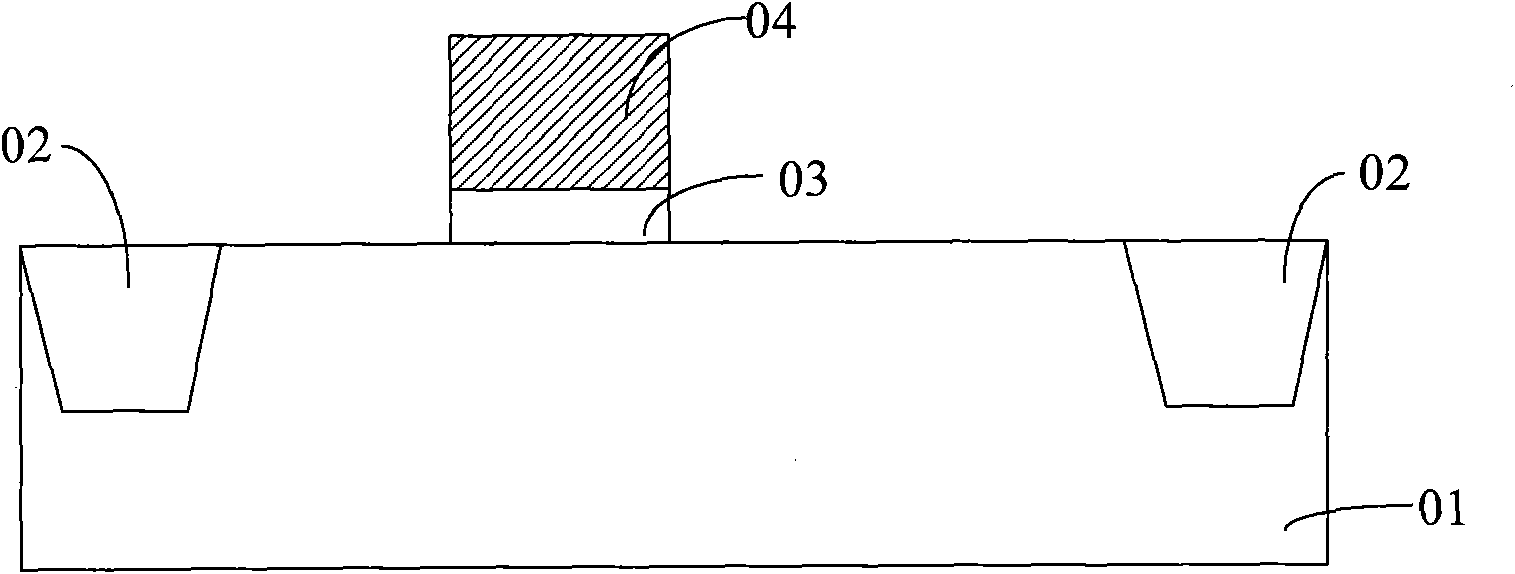

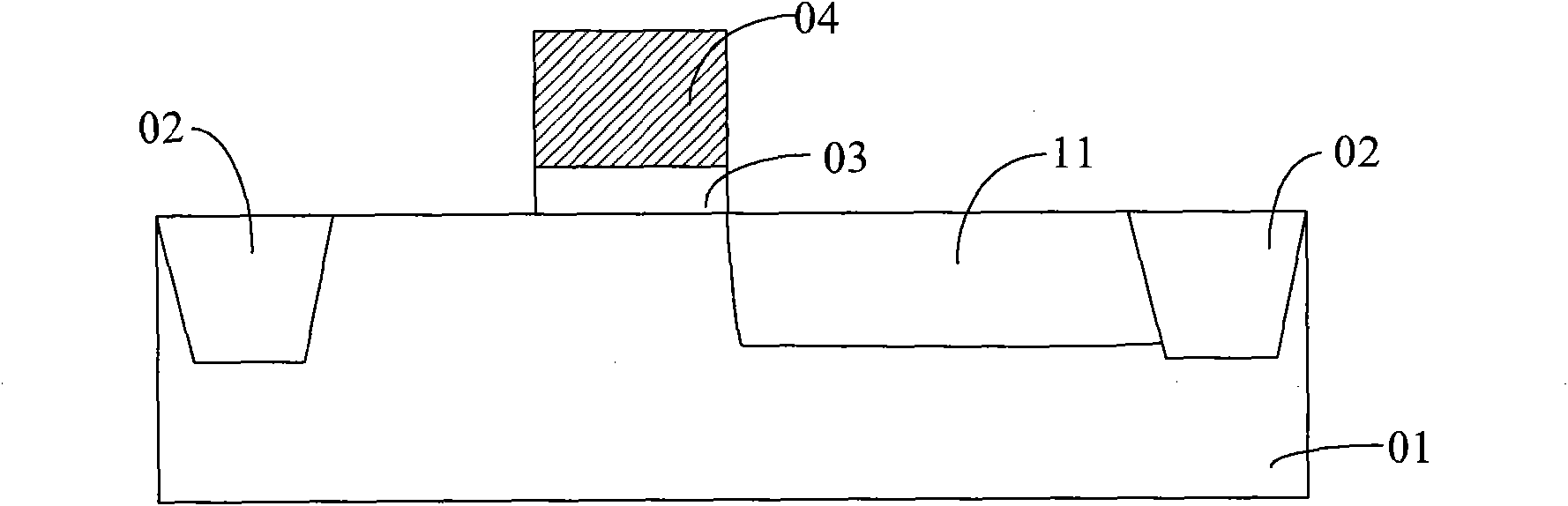

[0045] In order to solve the above problems, the invention provides a method for manufacturing a semiconductor device, such as Image 6 shown, including:

[0046]Step S101, providing a substrate, the substrate includes a vertically extended MOS transistor region, and the substrate has a first conductivity type;

[0047] Step S102, forming a lightly doped drain region in the substrate of the vertically extended MOS transistor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com