Coating, covered part with the coating and preparation method of covered part

A coating and coating technology, which is applied in the field of coatings, coated parts with the coating and the preparation of the coated parts, can solve the problem that the hardness and wear resistance of ZrN films are not improved, and it is difficult to meet the requirements of modern industry, toughness and resistance. Poor wearability and other problems, to achieve the effect of improving hardness and corrosion resistance, high corrosion resistance and small internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

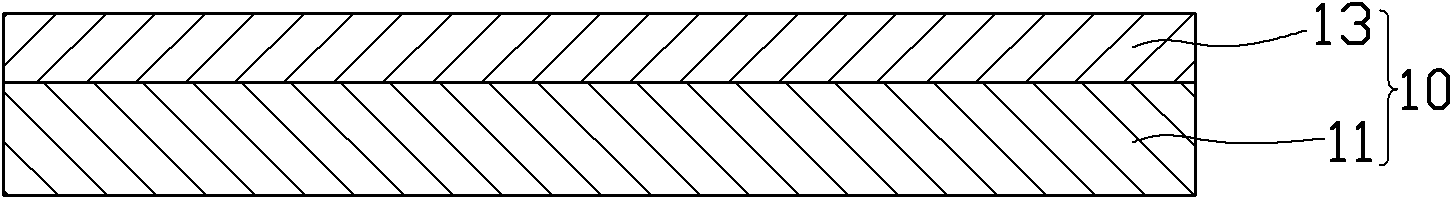

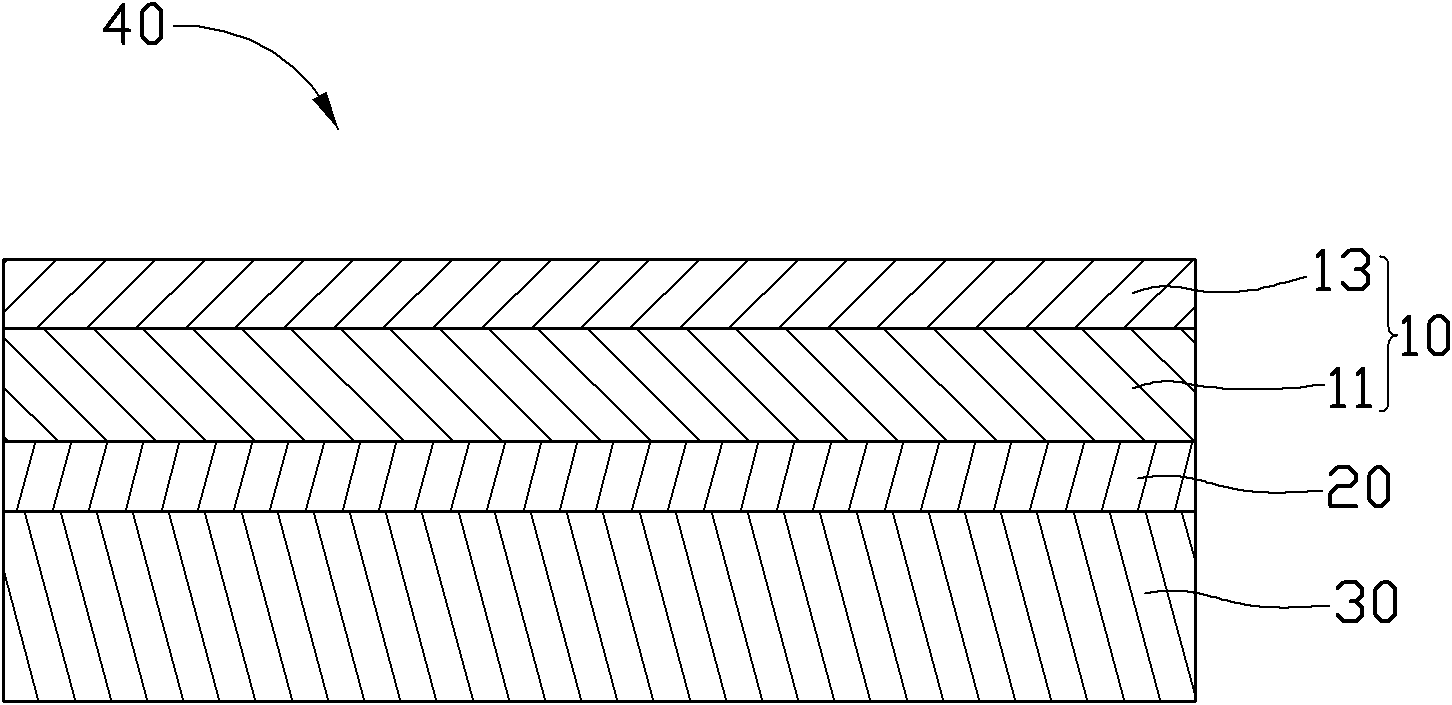

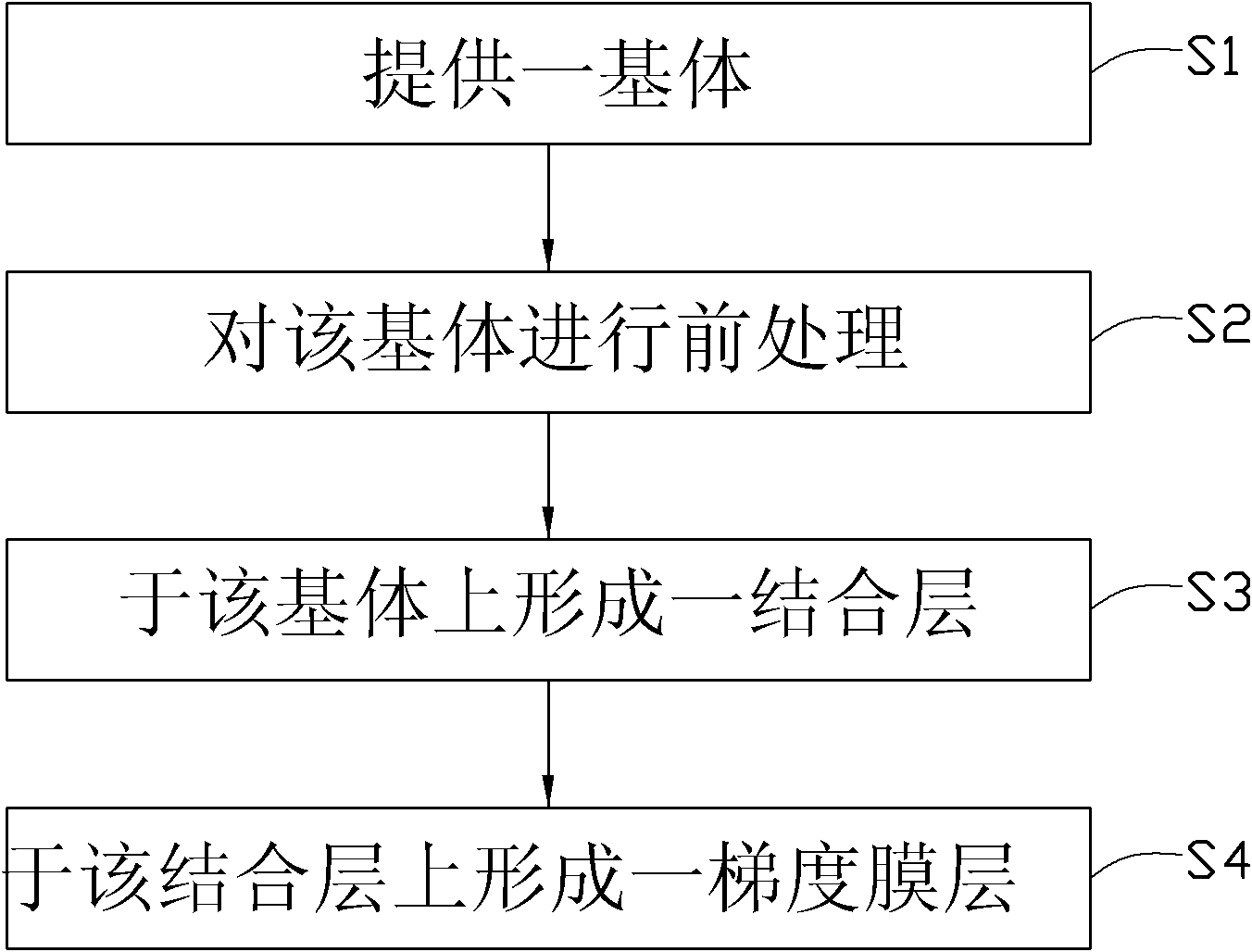

[0025] see figure 1 , the coating 10 of a preferred embodiment of the present invention includes a gradient film layer 11 , and the coating 10 is formed on the surface of a hard substrate 30 . The material of the hard substrate 30 can be high speed steel, hard alloy and stainless steel.

[0026] The gradient film layer 11 is a ZrBN layer with a thickness of 0.5-2 μm. The gradient film layer 11 is deposited and formed by magnetron sputtering. In this gradient film layer 11, the number and content of N atoms and B atoms all increase with the increase of the thickness of this gradient film layer 11, that is, the number and content of N atoms and B atoms in this gradient film layer 11 are from close to The direction from the hard base 30 to the direction away from the hard base 30 increases gradually.

[0027] It can be understood that a color layer 13 may also be plated on the surface of the gradient film layer 11 to enhance the aesthetics of the coating layer 10 .

[0028] s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com