Foaming agent composition and purpose thereof

A technology of composition and foaming agent, which is applied in the direction of drilling composition, production fluid, wellbore/well parts, etc., can solve the problems of poor thermal stability of foaming agent and cannot meet the needs, and achieve the effect of improving salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

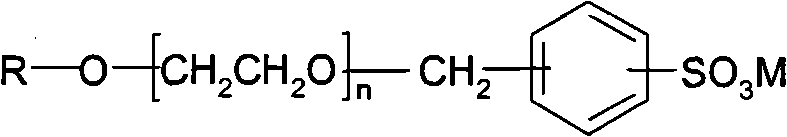

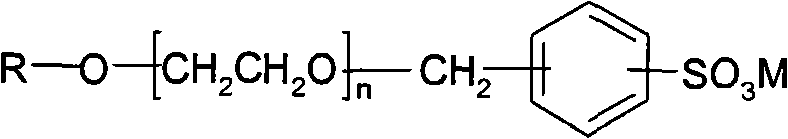

Image

Examples

Embodiment 1

[0025] (1) Add 93g (0.5 mole) dodecyl alcohol and the calcium oxide catalyst of alcohol weight 1% in the reactor that condensing device, stirring device and gas disperser are housed, when heating to 135 ℃ while flowing nitrogen, add 8g water , and stirred for 1 hour. Then first distilled water at normal pressure, then decompressed under 20 mm Hg vacuum, evaporated moisture at 140 DEG C in vacuum for 20 minutes, cooled the solution to 80 DEG C, slowly added dropwise neutralizing catalyst theoretical acid amount of 20% by weight concentrated sulfuric acid. Heat the system temperature to 80-90°C, turn on the vacuum system, dehydrate under high vacuum for 1 hour, then use nitrogen to blow 3-4 times to remove the air in the system, then adjust the reaction temperature of the system to 150°C Enter 155 grams of oxirane, control pressure<0.60MPa to carry out alkoxylation reaction; Obtain lauryl alcohol polyoxyethylene (7) ether.

[0026] (2) 240g (0.5 mole) of polyoxyethylene laury...

Embodiment 2

[0034] Get the foaming agent composition in [Example 1] and put it into a pressure bomb, put it into an oven and age it at 150°C for 10 days, take it out, and measure the foaming ability and foam of the composition after aging under the condition of 85°C water bath by Roche method The results of the half-life measured by the scanner are shown in Table 3.

[0035] table 3

[0036] X(weight)%

Embodiment 3

[0038] Get the foam composition lauryl alcohol polyoxyethylene (7) ether sodium benzene sulfonate 0.5 (weight)% in [Example 1], α-olefin sulfonate AOS 14160.1 (weight)% to carry out the plugging performance evaluation test, the quartz sand fills the core tube with a permeability of 4D, injects the aqueous solution of the foam agent composition into the sand tube at a speed of 2mL / min, and simultaneously presses in nitrogen gas at a speed of 9mL / min to measure the plugging performance. The plugging pressure difference is 1.55MPa, and the calculated resistance factor is 38.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com