Method for preparing gelatin

A gelatin and gelatin boiling technology, which is applied in the field of gelatin preparation from animal rubber raw materials, can solve the problems of long process time, high temperature for extracting gelatin, and low yield of high-quality gelatin, and achieve the effects of simplified process, short gelatin cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Wash the tilapia skin raw material with clean water to remove impurities, soak it in saturated lime water, replace it with fresh saturated lime water every 24 hours, wash the skin raw material after 6 days of liming to obtain coarse collagen fibers;

[0038] 2. Mechanically crushing the crude collagen fibers obtained in step 1, adding 0.10 mmol of hydrogen peroxide to each gram of crude collagen fiber material, adding water, and boiling at 50° C. for 4 hours to obtain a gelatin solution;

[0039] 3. Filter the gelatin solution obtained in step 2 through a filter cloth, concentrate in vacuum, dry in sections, and pulverize to obtain a gelatin product.

[0040] The yield of the prepared gelatin is 70%, and the viscosity is 5.11mpa.s.

Embodiment 2

[0042] 1. Wash the chicken aggregates with clean water, demineralize and remove impurities, soak them in saturated lime water, replace with fresh saturated lime water every 24 hours, and wash the bones after 12 days of liming.

[0043]2. Mechanically crush the bone bone material obtained in step 1, add 0.07 mmol of hydrogen peroxide per gram of the bone bone material, add water, boil at 72° C. for 6 hours to obtain a gelatin solution.

[0044] 3, (same as step 3 of embodiment 1.)

[0045] The yield of the prepared gelatin was 66%, and the viscosity was 5.34mpa.s.

Embodiment 3~14

[0047] Examples 3 to 14 are multiple examples of extracting gelatin by using different raw materials for rubber production.

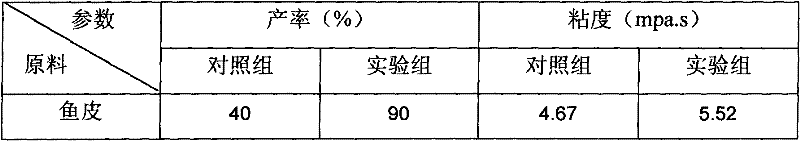

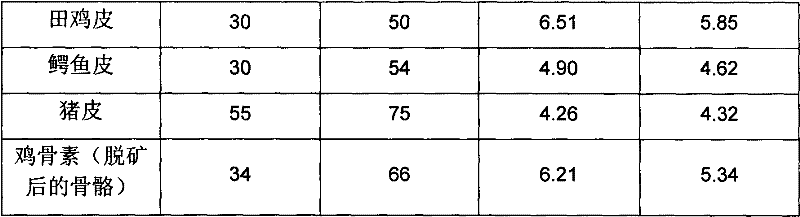

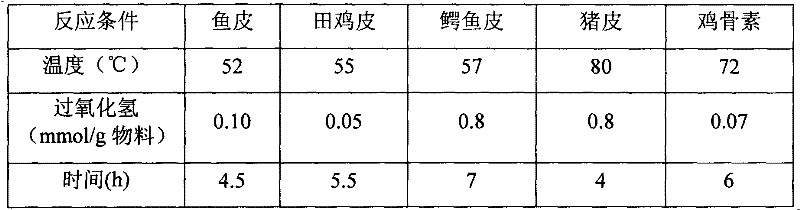

[0048] table 3

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com