Surface treatment technique of flow control valve

A flow control valve and surface treatment technology, applied in the field of processing technology, can solve problems such as increased leakage, increased fit gap between the flow control valve and the pump body, and affecting the performance of the steering pump of the automobile, so as to reduce the friction force and use The effect of life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

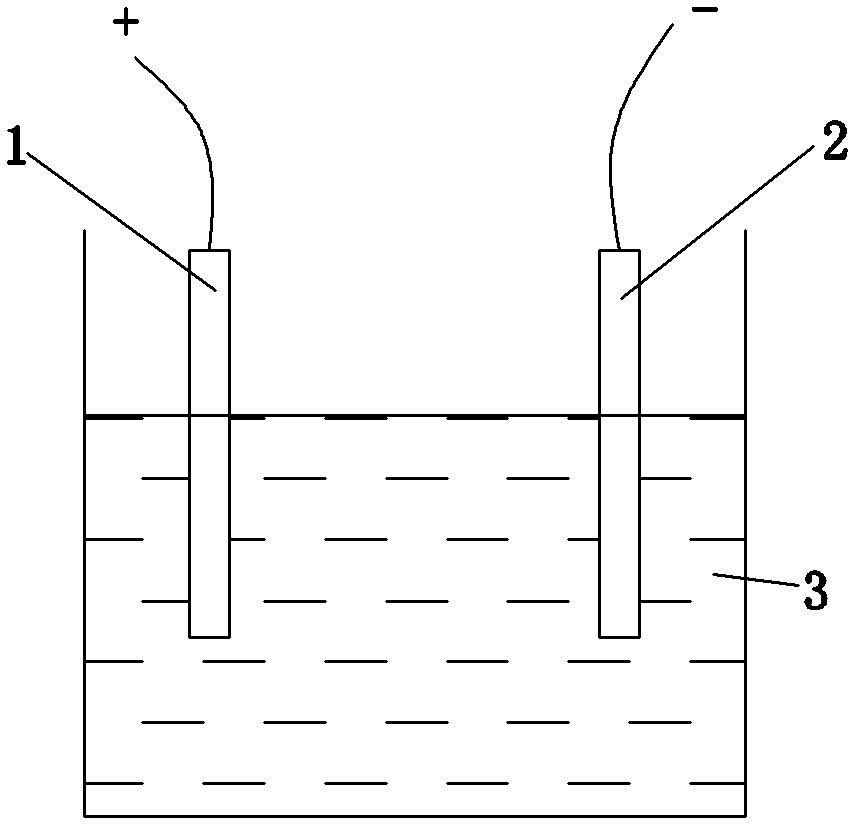

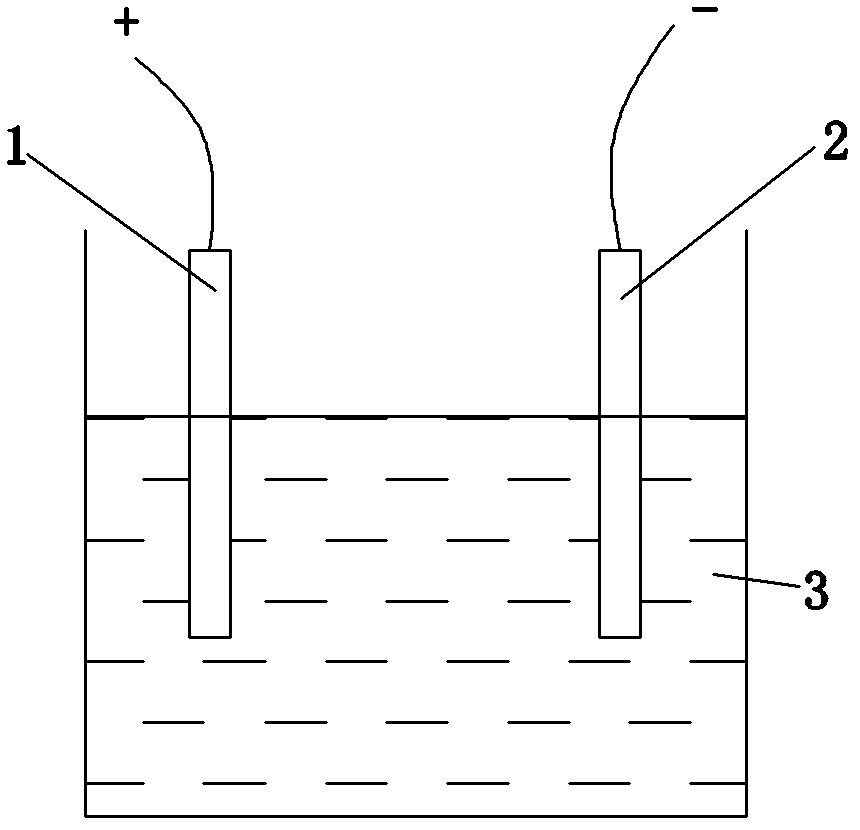

[0013] Such as figure 1 As shown, the flow control valve surface treatment process of the present invention, wherein the material used for the flow control valve is aluminum 6061, the flow control valve is used as the anode 1 and the lead plate is used as the cathode 2 during the treatment process, and the anode 1 and the cathode 2 are placed in the oxidizing solution In 3, the oxidation solution 3 is a mixed solution of 2.24mol / L sulfuric acid aqueous solution and 224mol / L polytetrafluoroethylene aqueous dispersion in a volume ratio of 3:1, the temperature of the mixed solution is -3°C, and the area of the cathode 2 is It is 10 times the area of the anode 1, and the DC power supply is connected. The stable oxidation current density of the anode 1 is 2.5A / dm. During the oxidation process, the oxidation solution 3 is stirred with a magnetic bar to absorb the magnetic impurities in the oxidation solution. In 2.5 hours, in the oxidation solution 3, the size of the polytetrafl...

Embodiment 2

[0015] Such as figure 1 As shown, the flow control valve surface treatment process of the present invention, wherein the material used for the flow control valve is aluminum 6061, the flow control valve is used as the anode 1 and the stainless steel plate is used as the cathode 2 during the treatment process, and the anode 1 and the cathode 2 are placed in the oxidizing solution In 3, the oxidation solution 3 is a mixed solution of 2.24mol / L sulfuric acid aqueous solution and 224mol / L polytetrafluoroethylene aqueous dispersion in a volume ratio of 3:1, the temperature of the mixed solution is -4°C, and the area of the cathode 2 is It is 10 times the area of the anode 1, and the DC power supply is connected. The stable oxidation current density of the anode 1 is 2.5A / dm. During the oxidation process, the oxidation solution 3 is stirred with a magnetic bar to absorb the magnetic impurities in the oxidation solution. For 3 hours, in the oxidation solution 3, the size of the p...

Embodiment 3

[0017] Such as figure 1 As shown, the flow control valve surface treatment process of the present invention, wherein the material used for the flow control valve is aluminum 6061, the flow control valve is used as the anode 1 and the lead plate is used as the cathode 2 during the treatment process, and the anode 1 and the cathode 2 are placed in the oxidizing solution In 3, the oxidizing solution 3 is a mixed solution of 2.24mol / L sulfuric acid aqueous solution and 224mol / L polytetrafluoroethylene aqueous dispersion in a volume ratio of 3:1, the temperature of the mixed solution is -3.5°C, and the area of the cathode 2 is It is 10 times the area of the anode 1, and the DC power supply is connected. The stable oxidation current density of the anode 1 is 2.5A / dm. During the oxidation process, the oxidation solution 3 is stirred with a magnetic bar to absorb the magnetic impurities in the oxidation solution. In 2.7 hours, in the oxidation solution 3, the size of the polytetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com