Method and device for removing surface scale of copper and copper alloy ingot before rolling

A process method and copper alloy technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of reduced production efficiency, increased production cost, and increased energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be described in further detail below through embodiments and in conjunction with the accompanying drawings.

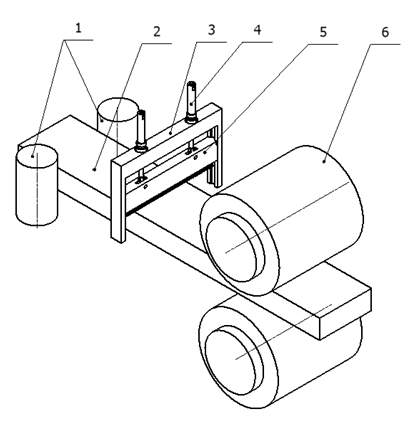

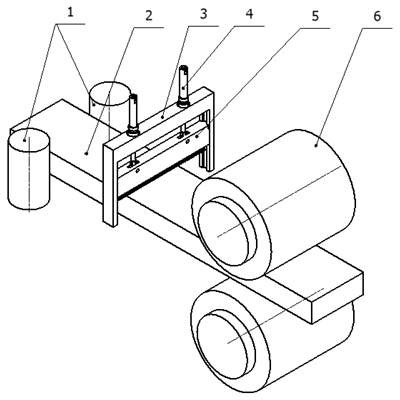

[0017] Such as figure 1 As shown, the device for removing oxide skin on the surface of copper and copper alloy ingots before rolling includes vertical rollers and steel brush devices arranged in sequence at the front end of the hot rolling mill. Two vertical rollers 1 are symmetrically arranged on the copper and copper alloy casting On both sides of the ingot 2, the steel brush device consists of a bracket 3, a steel brush 5 mounted on the bracket and a hydraulic cylinder 4. The hydraulic cylinder 4 is located above the steel brush 5, and the piston rod of the hydraulic cylinder is connected to the upper part of the steel brush.

[0018] The above-mentioned steel brush adopts a plate-type steel brush, a roller-type steel brush, an arc-shaped steel brush or a round steel brush.

[0019] Above-mentioned vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com