Method for directly preparing anhydrous cobalt chloride powder from cobalt chloride solution

A technology of cobalt chloride and solution, applied in the directions of cobalt halide, spray evaporation, etc., can solve the problems of long process flow, difficult sieving, long time consumption, etc., and achieve the effect of simple process flow, uniform particle size and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with specific embodiment the present invention is described:

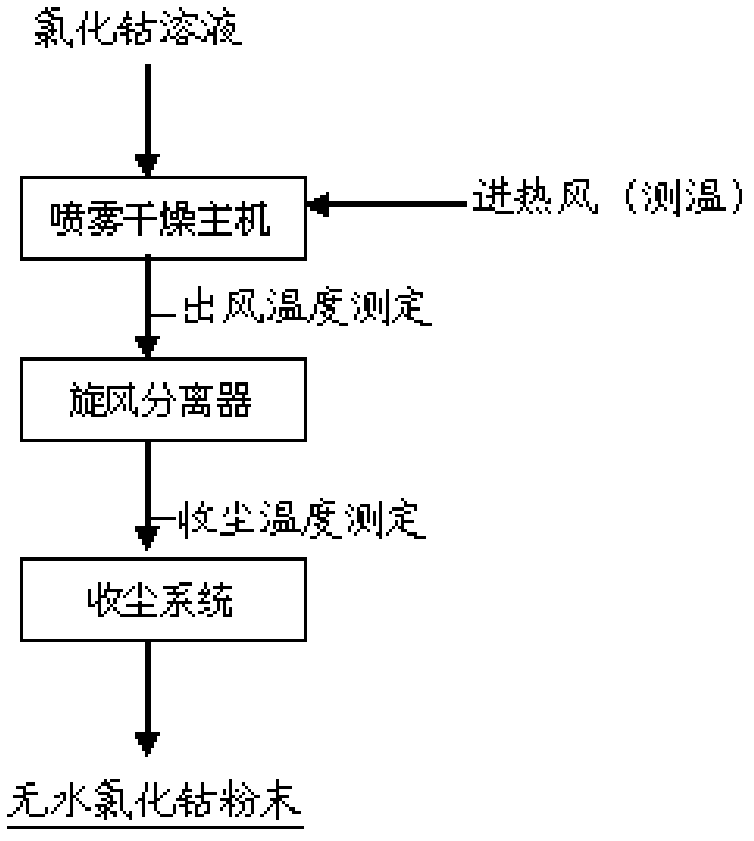

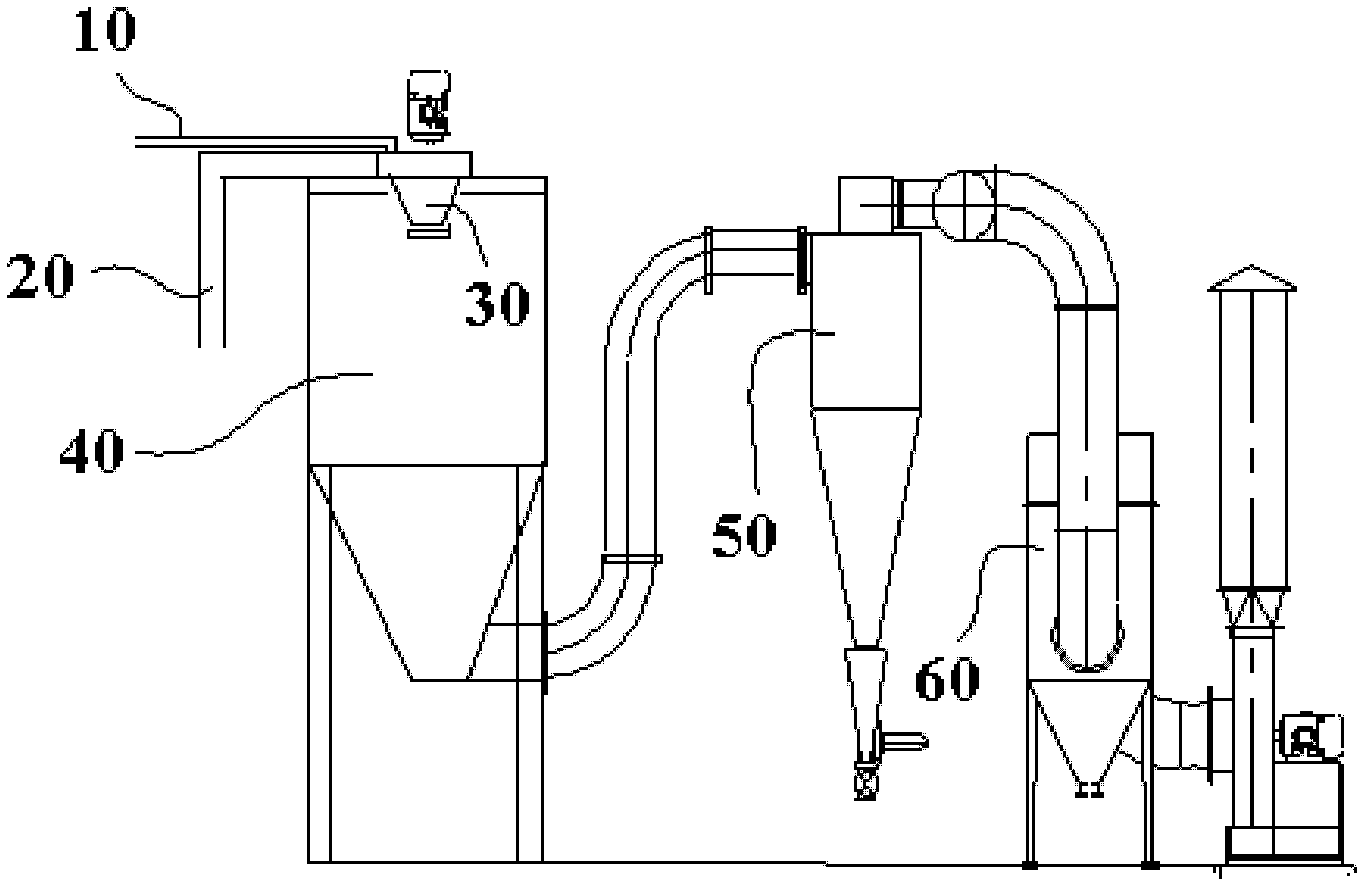

[0015] Such as figure 1 and 2 As shown, the equipment for directly producing cobalt chloride powder from cobalt chloride solution includes spraying main equipment and auxiliary equipment, wherein, reference numeral 10 indicates that cobalt chloride solution is added to the channel, and reference numeral 20 indicates that hot air provides channels; Reference numeral 30 represents an atomizer; reference numeral 40 represents a spray drying chamber; reference numeral 50 represents a cyclone separator; and reference numeral 60 represents a high-temperature plastic plate dust collector.

[0016] The air is converted into hot air through the heater, enters the hot air distributor on the top of the spray drying chamber, and enters the drying room. In the spiral state, at the same time, the cobalt chloride solution with a cobalt concentration of 80--130g / L is pumped into the high-speed centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com