Natural fruit and vegetable ferment beverage, and preparation method thereof

A fruit and vegetable enzyme and beverage technology, which is applied in food preparation, yeast-containing food ingredients, bacteria used in food preparation, etc., can solve problems such as changes in quality and flavor, and achieve the effect of disease prevention and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

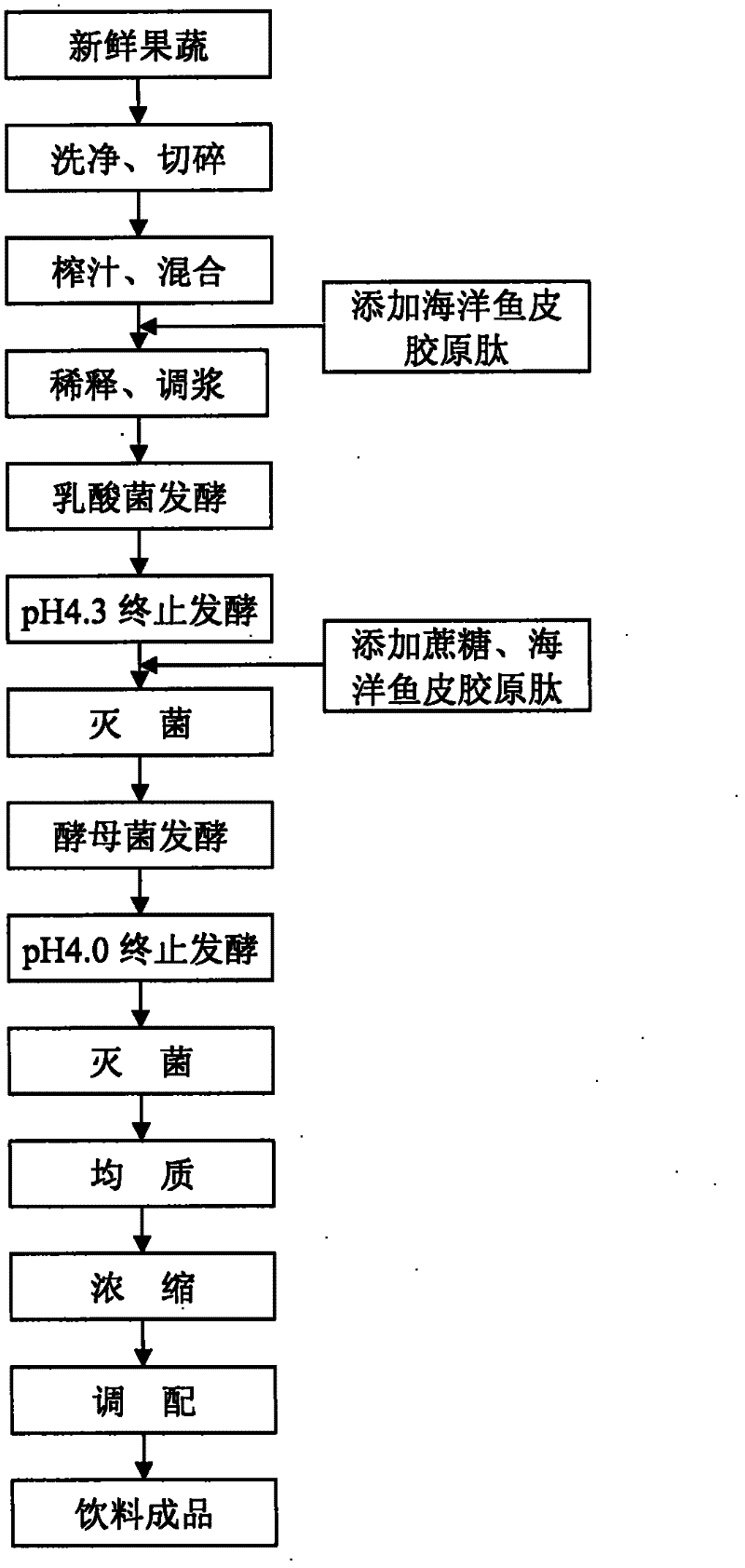

Image

Examples

Embodiment 1

[0026] Take fresh white apples, pineapples, red grapes, Fengshui pears, tomatoes, cabbage, celery, and cucumbers each 1kg, wash and cut into pieces, squeeze the juice, mix the fruit and vegetable juices, add the same volume of pure water to dilute the slurry, and then Add 2% marine fish skin collagen peptide powder (w / v), sterilize in a fermenter and cool down. Add 2U / 1000L of direct-injection freeze-dried lactic acid starter strains, ferment for 7 days at a temperature of 30°C, and stop the fermentation when the pH reaches 4.3. Then 1% sucrose (w / v) and 1% marine fish skin collagen peptide powder (w / v) were added, high temperature sterilized and cooled. Add 0.08% highly active dry yeast, ferment for 5 days at a temperature of 25° C., terminate the fermentation when the pH reaches 4.0, sterilize at high temperature and cool down. Store in a low-temperature storage tank at 8°C for 15 days.

[0027] The fermented liquid was homogenized at 40MPa for 10min, then concentrated in ...

Embodiment 2

[0029] Take 5kg each of fresh red apple, watermelon, blueberry, lemon, green pepper, winter melon, asparagus, and sea cabbage, wash and cut into pieces, squeeze the juice, mix the fruit and vegetable juice, add the same volume of pure water to dilute the paste, and then add 2.5% marine fish skin collagen peptide powder (w / v), sterilized in a fermenter and cooled. Add 3U / 1000L of direct injection freeze-dried lactic acid starter strains, ferment for 10 days at a temperature of 35°C, and stop the fermentation when the pH reaches 4.3. Then 1.2% sucrose (w / v) and 1.2% marine fish skin collagen peptide powder (w / v) were added, high temperature sterilized and cooled. Add 0.10% highly active dry yeast, ferment for 6 days at a temperature of 28°C, terminate the fermentation when the pH reaches 4.0, sterilize at high temperature and cool down. Store in a low-temperature storage tank at 10°C for 18 days.

[0030] The fermented liquid was homogenized at 40MPa for 12min, then concentrat...

Embodiment 3

[0032]Take 10kg each of fresh kiwi fruit, papaya, navel orange, brown plum, white radish, zucchini, oyster mushroom, and enoki mushroom, wash and cut into pieces, squeeze the juice, mix the fruit and vegetable juices, add the same volume of pure water to dilute slurry, then add 2% marine fish skin collagen peptide powder (w / v), sterilize in a fermenter and cool down. Add 4U / 1000L of direct injection freeze-dried lactic acid starter strains, ferment for 10 days at a temperature of 35°C, and stop the fermentation when the pH reaches 4.3. Then add 1.5% sucrose (w / v) and 1.5% marine fish skin collagen peptide powder (w / v), high temperature sterilization and cooling. Add 0.12% highly active dry yeast, ferment for 7 days at a temperature of 30° C., terminate the fermentation when the pH reaches 4.0, sterilize at high temperature and cool down. Store in a low-temperature storage tank at 12°C for 20 days.

[0033] The fermented liquid was homogenized at 40MPa for 15min, then concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com